SCF Self Cleaning No Mesh Melt Filter For Plastic Recycling Pelletizing Machine

Screen changer

The screen changer is a manual or automatic switching device consisting of one or more filters, which is used to filter out foreign particles and impurities when plasticizing material flow filters. As we all know, the cleanliness of the recycled materials and the technological use of the final regenerated particles determine the filtration technical standards of the filtration system. For different melt filtration loads, the conventional non-stop single-plate double-station or two-piston double-station screen-changing filtration system is applied to achieve excellent melt filtration performance.

SCF Self Cleaning No Mesh Melt Filter For Plastic Recycling Pelletizing Machine

The new SCF self-cleaning filtration system makes non-stopping recycling extrusion, especially suitable to highly contaminated materials re-pelletizing.

Different from traditional screen changers, which requires timely change the dirty wire mesh, the SCF system will present continuous filtering performance, and remove the contaminates from the surface of steel screen plate automatically.It has the advantages of a high degree of automation and large-volume production, which can increase the recycling rate of recycled materials, and the slag discharge rate (the amount of slag discharged and the plastic content in the accompanying slag discharge process) can reach 1:1.

Product Parameters:

| Model | SCF350 |

SCF350-D | SCF500D |

|

Diameter

|

350mm*1

|

350mm*2 | 500mm*2 |

| Filtration area | 961c㎡ |

1922c㎡

| 2700c㎡ |

|

Filtration fineness(mesh) | 40-120 |

40-120

| 40-120 |

|

Filtration fineness(um)

| 120-380 | 120-380 | 120-380 |

| Hole shape | Cylinder/Cone |

Cylinder/Cone

| Cylinder/Cone |

| Processing technic | CNC/Laser |

CNC/Laser

| CNC/Laser |

| Max.melt pressure | 200Bar |

200Bar

| 300Bar |

|

Max.melt difference |

150Bar

|

150

Bar

| 150 Bar |

| Throught capacity |

200-500kg/h

|

500

-1000

kg/h

| 600-1200kg/h |

| Rotation motor power | 2.2 kw |

2.2 kw

| 7.5kw |

| Discharge scrw motor power |

0.37

kw |

0.37 kw

*2

| 0.55kw*2 |

| Heating power |

28kw

| 33kw

| 48kw |

| Dirt discharge |

Screw

|

Screw

| Screw |

| PLC | Siemens |

Siemens

| Siemens |

| Inverter | Schneider/ABB | Schneider/ABB | Schneider/ABB |

SCF Self-cleaning Filtration System

The effective accuracy of SCF can reach 120 meshes. The use of Aceretech SCF self-cleaning filters can more efficiently produce pelletizing lines with an output of more than one ton per hour.

The SCF filtration system consists of hardened steel screen plate, rotating unit,hydraulic section, contaminates removing blades and discharging screw.

SCF filtration system can handle and remove up to 5% contaminates in the melt flowing, can separate the contaminates as: paper,wood, aluminum, unmelted plastic and rubbers etc.

SCF Typical Features

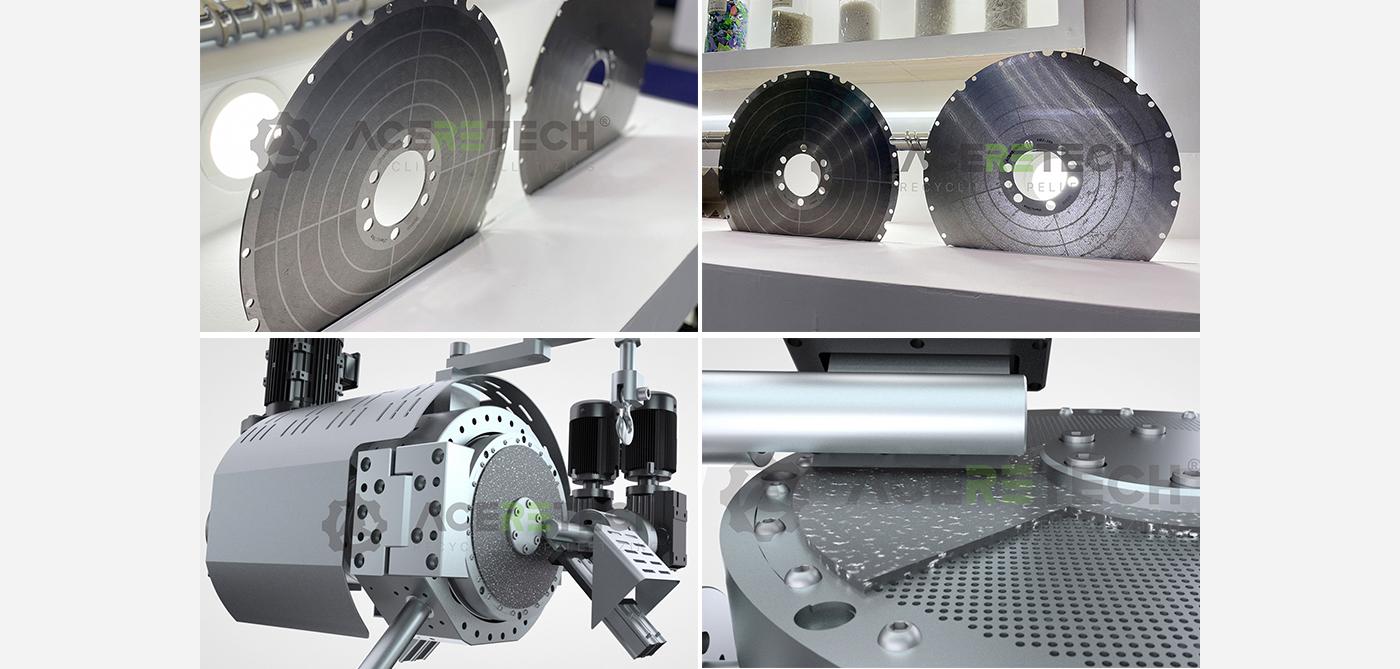

SCF Product Display

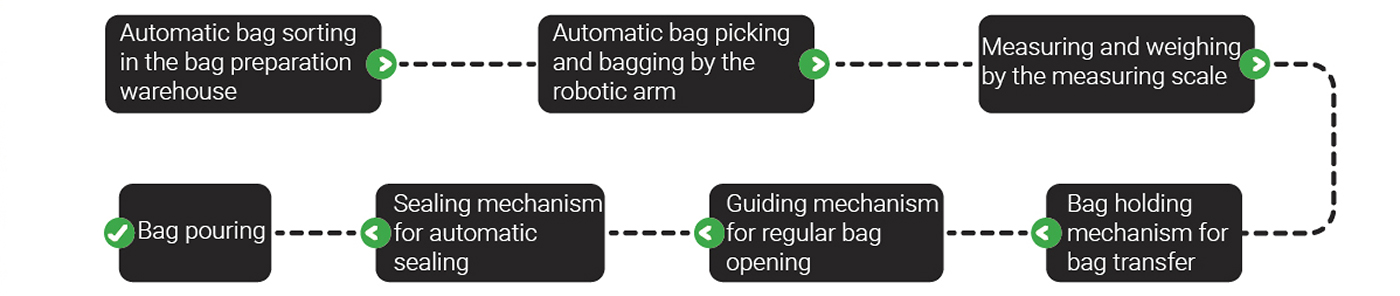

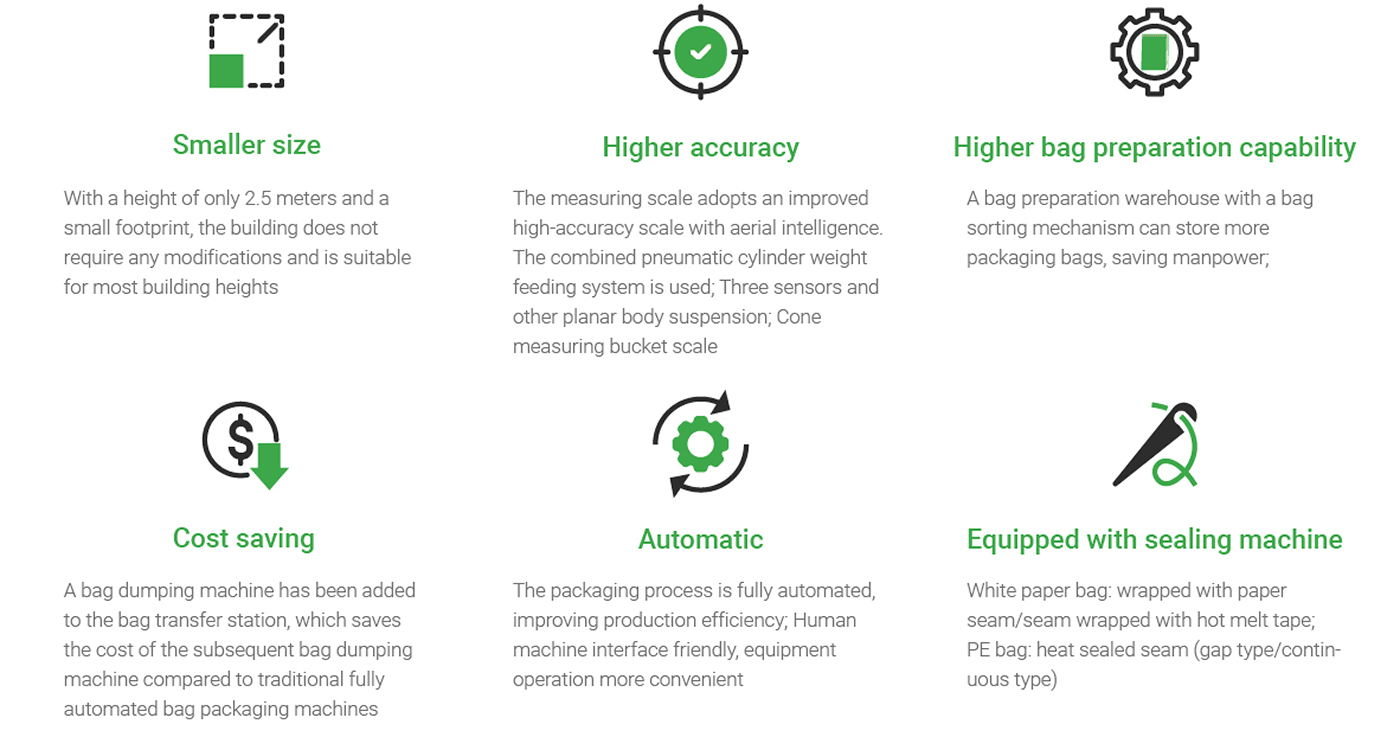

Product Features

Parameters

|

Model

|

Material to be packaged

|

Weighing range

|

Packing speed | Packing accuracy | Power |

|

|

Pellets |

20-25kg/bag

|

200bag/h | ±0.1% | 2kw |

|

ACGS-DA(R)

|

Gas consumption

|

Weight

|

Working condition

|

Air pressure

|

Noise

|

|

|

18 m ³ /h |

1.5-2t

|

0-40℃

|

0.5-0.7MPa

|

≤ 75db |

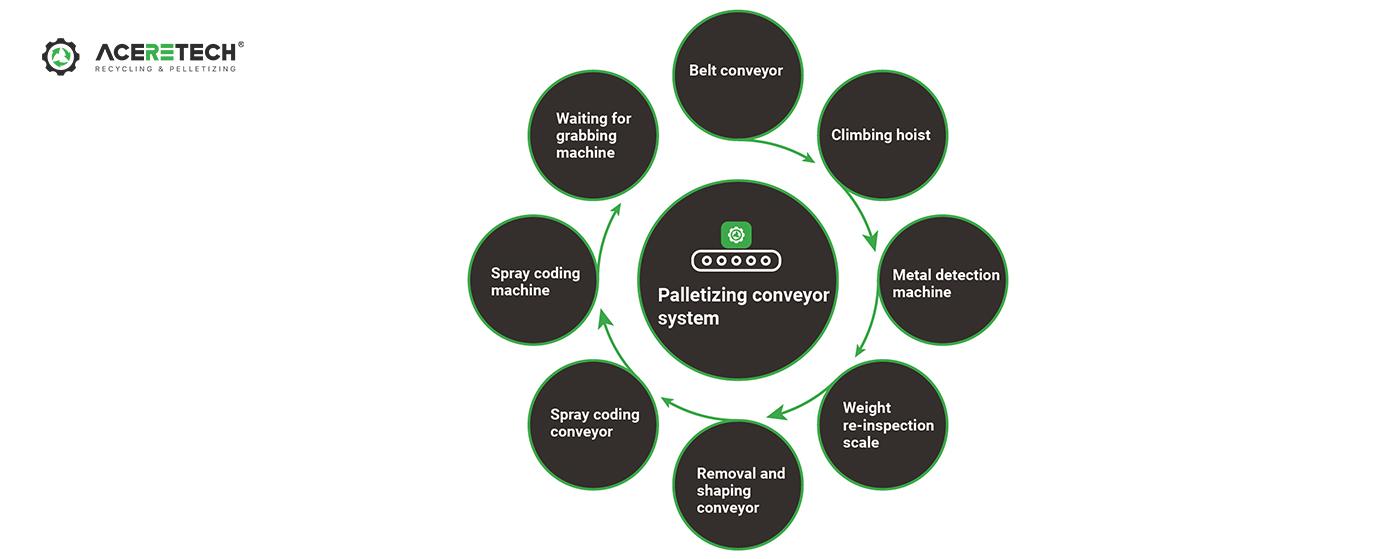

Palletizing Conveyor System

After the sealed package is poured onto the receiving belt conveyor, the climbing conveyor lifts the package to the required height for robot palletizing and grabbing. It then enters the weight recheck scale to recheck the accuracy. Products with unqualified accuracy are removed by the removal and shaping machine, while qualified products are shaken and shaped by the vibration shaping and pressing conveyor. After shaping is completed, the package is transported to the position of the coding

conveyor for coding. After coding is completed, the package is transported to the grabbing conveyor and waiting for the robot to grasp the palletizing.

Palletizing Conveyor System Including

Stacking Robot System

* Adopting ergonomic design, comfortable and lightweight operation ;

* Display in both Chinese and English, with a user-friendly interface ;

* Dual safety switch, fully ensuring the safety of personnel operation ;

* Equipped with USB interface, supporting import/ export of teaching programs ;

Tray Storage System

The pallet storage warehouse transports empty pallets to the palletizing conveyor through the empty pallet conveyor and waits for the robot to palletize them. When there are material packages on the grabbing conveyor, the robot starts palletizing and stacks them onto the pallet of the palletizing conveyor; Complete the palletizing operation according to the prescribed grouping mode, and the full stack of material packages will enter the online winding machine for automatic film wrapping, and then be covered with film on the top by the top covering machine; The wrapped products enter the full stack fork picking conveyor and wait for the forklift to pick them up.