Technical Differences, Best Applications, and How to Choose the Right Solution

Choosing the right extruder is one of the most critical decisions in a plastic recycling line. The choice between a single-screw and a twin-screw extruder directly affects material compatibility, product quality, operating stability, and long-term return on investment.

This in-depth comparison explains the technical differences, application scenarios, and decision logic behind twin-screw and single-screw extruders, helping recyclers and manufacturers select the most suitable solution for their specific recycling challenges.

What Is the Difference Between Single-Screw and Twin-Screw Extruders?

Core takeaway:

Single-screw extruders prioritize simplicity and cost efficiency, while twin-screw extruders excel in material mixing, degassing, and processing complex recycling feedstocks.

Single-Screw Extruders

Single-screw extruders rely on a single rotating screw to convey, melt, and homogenize plastic materials. Their design is straightforward, making them reliable and energy-efficient for stable and uniform input materials.

Key characteristics:

Simple mechanical structure

Lower initial investment

Easier operation and maintenance

Best suited for clean, consistent materials

Twin-Screw Extruders

Twin-screw extruders use two intermeshing screws that provide enhanced conveying, mixing, and devolatilization performance. This makes them particularly effective for challenging recycling materials.

Key characteristics:

Superior mixing and dispersion

Strong degassing capability

Higher tolerance for contaminated or blended materials

Greater process control flexibility

Which Extruder Works Best for Different Plastic Recycling Materials?

Core takeaway:

Material complexity is the primary factor that determines whether a single-screw or twin-screw extruder is the better choice.

Best Applications for Single-Screw Extruders

Single-screw systems perform best when the material stream is stable and predictable.

Typical applications include:

Clean post-industrial scrap

Uniform films or rigid plastics

Low-moisture, low-contamination materials

In these scenarios, single-screw extruders offer reliable output with lower operating costs.

Best Applications for Twin-Screw Extruders

Twin-screw extruders are designed for complex and demanding recycling tasks.

Typical applications include:

Mixed or contaminated post-consumer plastics

Engineering plastics and blends

Fiber-reinforced or heavily printed materials

Materials requiring intensive degassing

Their ability to manage variability makes twin-screw systems ideal for advanced recycling operations.

How Do Performance and Product Quality Compare?

Core takeaway:

Twin-screw extruders provide more consistent output quality when processing unstable or contaminated materials.

Performance differences become especially visible when recycling conditions are less than ideal. Twin-screw systems offer:

Improved melt homogeneity

More stable pressure and temperature control

Reduced risk of unmelted particles

Single-screw extruders, however, remain highly efficient for standard recycling lines where feedstock quality is controlled.

What Are the Cost Differences and ROI Considerations?

Core takeaway:

Lower upfront cost does not always mean lower long-term cost.

Initial Investment

Single-screw extruders typically require lower capital expenditure.

Twin-screw extruders involve higher upfront investment due to their complex design.

Long-Term ROI

Twin-screw systems often deliver better long-term returns when:

Processing waste streams with high variability

Reducing downtime caused by material instability

Improving pellet quality and reducing rejects

For operations handling complex recycling materials, the performance advantages of twin-screw extruders can offset higher initial costs over time.

How Should Buyers Decide Between Twin-Screw and Single-Screw Extruders?

Core takeaway:

The best extruder choice is determined by material characteristics, output requirements, and long-term operational goals.

When selecting an extrusion system, decision-makers should evaluate:

Material type and contamination level

Desired output quality and consistency

Production capacity and flexibility

Maintenance capability and operating costs

Future expansion or material diversification plans

Rather than choosing based solely on price, recyclers should consider how well the system supports stable production and long-term scalability.

Industry Trend: Why Hybrid and Customized Solutions Are Gaining Attention

Core takeaway:

Modern recycling lines increasingly combine different technologies to balance cost and performance.

Many recycling projects now integrate:

Pre-treatment systems to stabilize input material

Customized screw designs

Advanced filtration and degassing modules

This trend reflects a shift from “one-size-fits-all” equipment toward application-specific recycling solutions.

In summary, single-screw extruders are best suited for clean and consistent recycling materials, while twin-screw extruders offer greater flexibility and performance for complex and contaminated feedstocks.

Single-Screw vs. Twin-Screw Extruders: Key Differences at a Glance

| Comparison Aspect |

Single-Screw Extruder |

Twin-Screw Extruder |

| Core Design |

Single rotating screw |

Two intermeshing screws |

| Mixing Capability | Basic | Excellent |

| Degassing Performance | Limited | Strong |

| Material Tolerance | Clean, uniform materials | Mixed, contaminated, or complex materials |

| Process Stability | High with stable feedstock | High even with variable input |

| Output Consistency | Good for standard recycling | Superior for demanding applications |

| Initial Investment | Lower | Higher |

| Operating Flexibility | Limited | High |

| Typical Applications | Post-industrial scrap, clean plastics | Post-consumer waste, blends, engineering plastics |

| Long-Term ROI | Cost-effective for simple materials | Strong ROI for complex recycling challenges |

Frequently Asked Questions (FAQ)

A: Under the same production capacity, single-screw extruders are usually more energy-efficient. This is because the single-screw structure is simple, the frictional heat generation efficiency is high, and there is no complex transmission system. However, if processing high-humidity or complex materials requiring deep degassing, twin-screw extruders, with their efficient degassing and homogenization capabilities, can reduce the scrap rate of secondary processing. From the perspective of comprehensive energy consumption per unit of qualified product, twin-screw extruders have an advantage in large-scale modification production.

A: Single-screw extruders perform better in terms of wear resistance. Due to the larger gap between the barrel and the screw and the robust structure of the single-screw machine, it is less sensitive to hard impurities. Due to the tight meshing of twin-screw extruders, hard foreign objects can easily cause screw jamming or tooth breakage. Recommendation: Regardless of which type you choose, a high-strength magnetic separator and melt filter must be installed at the front end.

A: No. They are complementary rather than substitutive. In the large-scale recycling of pure materials (such as PET bottle flakes, PE film industrial waste), single-screw extruders dominate due to their extremely high cost-effectiveness and stability. Twin-screw extruders mainly address the value enhancement (upcycling) process from waste materials to high-performance materials.

A: The cost difference mainly stems from:

Gearbox structure: Twin-screw extruders require high-torque, high-precision distribution gearboxes, which have extremely complex manufacturing processes.

Screw design: Twin screws typically use a modular (segmented) design, requiring higher-grade materials (such as high-performance alloy steel).

Control system: Twin-screw extruders are usually equipped with more sophisticated automated control systems to monitor complex process parameters.

A: The most advanced solution currently is the "single-screw plus twin-screw" two-stage extrusion granulation line. That is: the first stage uses a single-screw extruder with a large length-to-diameter ratio for pre-melting and coarse filtration, and the second stage uses a co-rotating twin-screw extruder for deep degassing, additive addition, and fine modification. This combination integrates the strong adaptability of single-screw extruders and the high dispersion capabilities of twin-screw extruders, making it the preferred solution for producing high-quality recycled materials.

Conclusion: Choosing the Right Extrusion Solution for Your Recycling Line

Selecting between a twin-screw and a single-screw extruder is not about choosing the “better” machine—it is about choosing the right solution for your materials and objectives.

A well-matched extrusion system improves product quality, reduces operational risk, and supports long-term business sustainability in plastic recycling.

Looking for Expert Guidance on Your Recycling Project?

If you are evaluating extrusion technologies or planning a new plastic recycling line, professional system design and material assessment can make a critical difference.

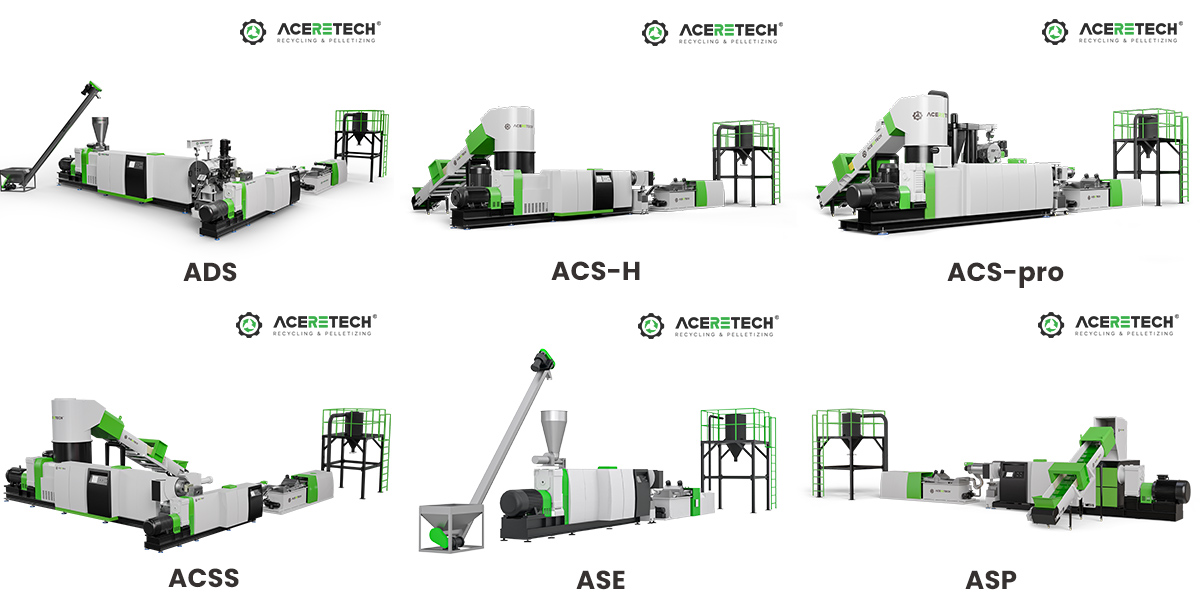

ACERETECH specializes in customized plastic recycling solutions, offering both single-screw and twin-screw extrusion systems tailored to real-world recycling challenges.

👉 Contact ACERETECH to discuss the optimal extrusion solution for your material and production goals.