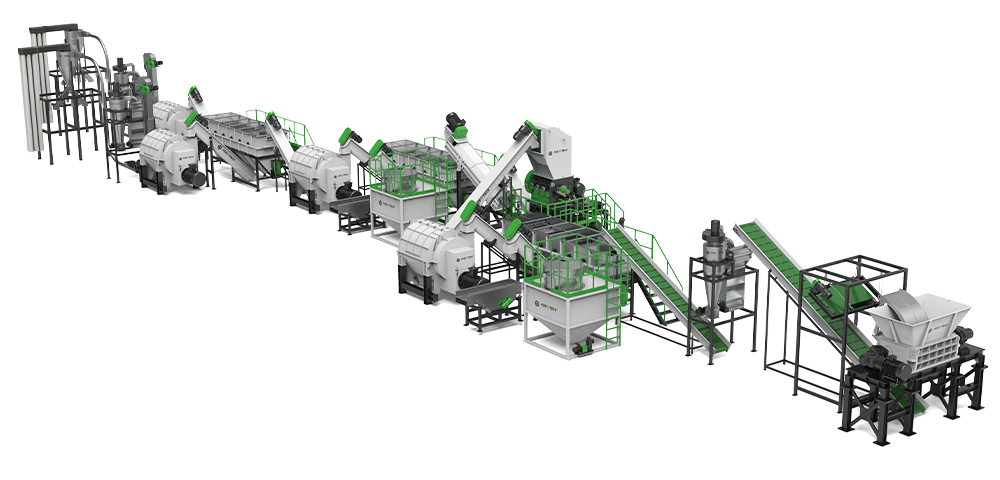

AWS-WEEE (waste appliances) washing and recycling machine

AWS-WEEE (Waste Appliances) Washing And Recycling Machine

According to the Waste Electrical Equipment Directive stipulated by China's regulations, the goal is to reduce millions of tons of waste plastics every year, such as household appliances, computers, toys, and so on.

1.Large Household Appliances

2.Small Household Appliances

3.It And Telecommunications Equipment

4.Consumer Equipment

5.Lighting Equipment

6.Electrical And Electronic Tools

7.Toys, Leisure And Sports Equipment

8.Medical Equipment

9.Monitoring And Control Equipment

10.Automatic Distributor

ACERETECH team has many years of research and development experience in household appliance cleaning and recycling lines and has designed cleaning and recycling solutions for cleaning, separating, and drying plastic and electronic equipment waste.

The PS/ABS recycling line developed by the ACERETECH team uses density separation (salt water) to achieve high purity PS and ABS materials with consistent performance.

♲ PE/PP purity: >98%

♲ PS purity: >92%

♲ ABS purity: ≥92%

Used in recycling used refrigerators to obtain high purity plastics, non-ferrous metals, and non-ferrous metals and foams.

The refrigerator recycling line from ACERETECH is the domestic leading technology level and has a cyclopentane alarm system, dust removal system, and fire protection system to protect personal and property safety.

♻ Production: 40-55 units/hour, 80-100 units/hour

♻ Iron screening rate (weight): >98%

♻ Aluminum, copper screening rate (weight): >92%

♻ Plastic screening rate (weight) ≥90%

♻ Polyurethane foam collection efficiency (weight): >90%

Why Choosing ACERETECH?

As one of the major players in China's plastics recycling industry, ACERETECH can design recycling solutions for cleaning, separating, and drying plastics for various weee (Waste Electrical and. Electronic Equipment) plastics (WEEP) recycling. High-efficiency waste treatment and high-purity recycled plastics output are the advantages that we can stand firm in the market. Our recycling lines can process all kinds of waste plastics, such as PE, PS, PET, ABS, HDPE, Thermoplastic, etc. If you have any need for plastic recycling machines, please feel free to write to the service team to discuss the best recycling solution.

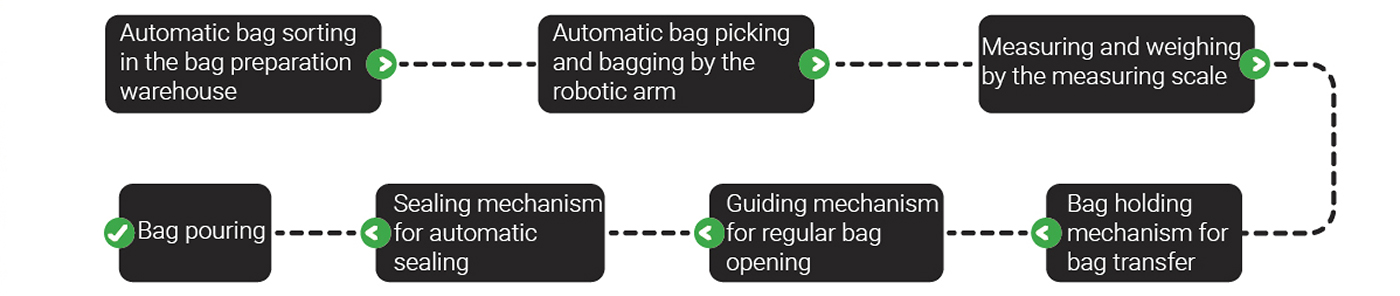

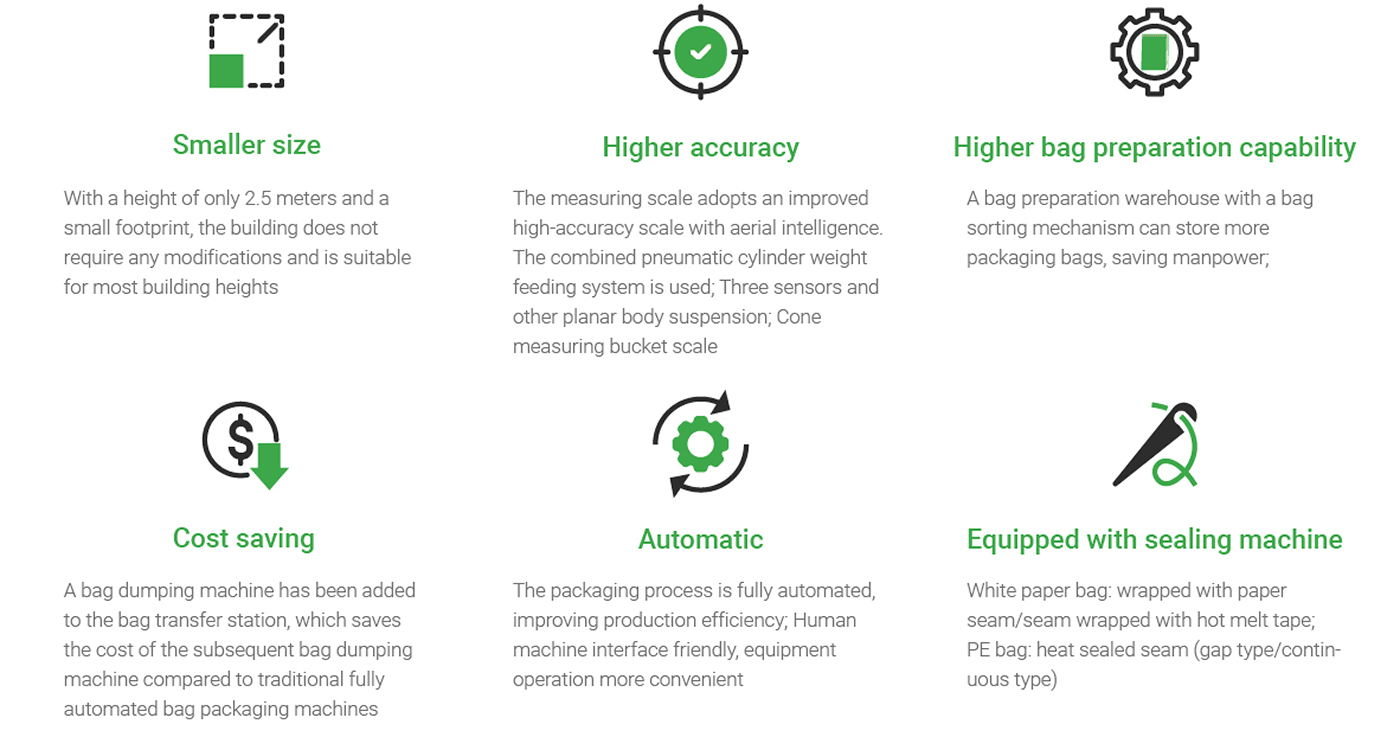

Product Features

Parameters

|

Model

|

Material to be packaged

|

Weighing range

|

Packing speed | Packing accuracy | Power |

|

|

Pellets |

20-25kg/bag

|

200bag/h | ±0.1% | 2kw |

|

ACGS-DA(R)

|

Gas consumption

|

Weight

|

Working condition

|

Air pressure

|

Noise

|

|

|

18 m ³ /h |

1.5-2t

|

0-40℃

|

0.5-0.7MPa

|

≤ 75db |

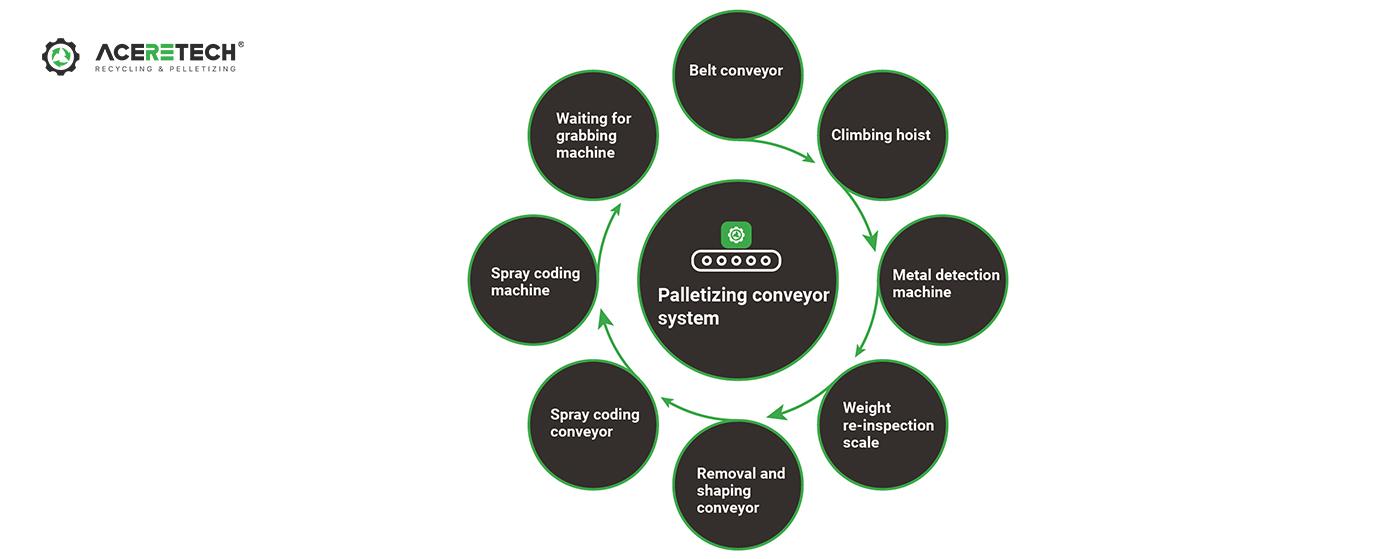

Palletizing Conveyor System

After the sealed package is poured onto the receiving belt conveyor, the climbing conveyor lifts the package to the required height for robot palletizing and grabbing. It then enters the weight recheck scale to recheck the accuracy. Products with unqualified accuracy are removed by the removal and shaping machine, while qualified products are shaken and shaped by the vibration shaping and pressing conveyor. After shaping is completed, the package is transported to the position of the coding

conveyor for coding. After coding is completed, the package is transported to the grabbing conveyor and waiting for the robot to grasp the palletizing.

Palletizing Conveyor System Including

Stacking Robot System

* Adopting ergonomic design, comfortable and lightweight operation ;

* Display in both Chinese and English, with a user-friendly interface ;

* Dual safety switch, fully ensuring the safety of personnel operation ;

* Equipped with USB interface, supporting import/ export of teaching programs ;

Tray Storage System

The pallet storage warehouse transports empty pallets to the palletizing conveyor through the empty pallet conveyor and waits for the robot to palletize them. When there are material packages on the grabbing conveyor, the robot starts palletizing and stacks them onto the pallet of the palletizing conveyor; Complete the palletizing operation according to the prescribed grouping mode, and the full stack of material packages will enter the online winding machine for automatic film wrapping, and then be covered with film on the top by the top covering machine; The wrapped products enter the full stack fork picking conveyor and wait for the forklift to pick them up.