ASD Plastic Film and Bag Recycling Squeezer

ASD Plastic Film and Bag Recycling Squeezer

The new ASD plastic squeeze dryer is especially suitable for soft plastics dewatering and drying, such as films and woven bags. It can be equipped with plastic film washing lines or alone. Compared with the traditional way of centrifugal dryer and pipeline dryer, the new ADS plastic squeezer with advantages of small footprint, low energy consumption, and low noise.

Product Description:

The new ASD plastic squeezer dryer consists of of main motor, gear box, barrel &screw, die head, pelletizing device and main control cabinet.

The specially designed planetary gearbox and the independently developed thrust bearing seat give the screw a strong thrust and reduce energy consumption. The independently developed thrust bearing seat can bear the axial thrust generated by the equipment during operation, protect the equipment and extend its service life.

Material fed into barrel&screw through the hopper, then motor driven screw forward, material pass through the high-strength die, then to the pelletizing device and be made into semi-plasticized granules finally, which can be directly secondary granulation or sale.

The new ASD plastic squeezer can control material final moisture within 5-7% effectively and capacity range from 300-800 kg/h.

Advantages:

- Strong thrust, low power consumption and high performance

- More stable operation and long equipment life

- Low noise and less space required

- Achieved moisture of material under 5-7%

- Cut frequency control, uniform and stable.

- PLC automatic control, simpler operation and more convenient maintenance.

- Semiplastified granules can be used for pelletizing or sold directl.

Product Parameters:

| Model | ASD300 | ASD320 |

| Main Motor Power | 90kw | 132kw |

| Granulating Motor Power | 4kw | 5.5kw |

| Squeezing Screw Diameter | 300mm | 320mm |

| Equipment Weight | ~4500KG | ~6000KG |

| Capacity | 300-500kg/h | 400-550kg/h |

| Rotating speed | 65rpm | 65rpm |

| Speed of cutting | 400rpm | 400rpm |

| Diameter of final granule | ≥12mm | ≥12mm |

| Fan power | 5.5kw | 5.5kw |

| Volume of Silo | 0.7CBM | 0.7CBM |

Aceretech Machinery is one of the leading companies in China for plastic recycling technology and solutions. Aceretech offers high-efficiency integrated equipment for plastic washing, re-granulation, and waste management. We are constantly innovating and developing new, scalable, and sustainable processes to handle various types of plastic waste. Our goal is to help you turn waste into wealth and protect the environment at the same time. Contact us today and let us help you with your plastic recycling needs.

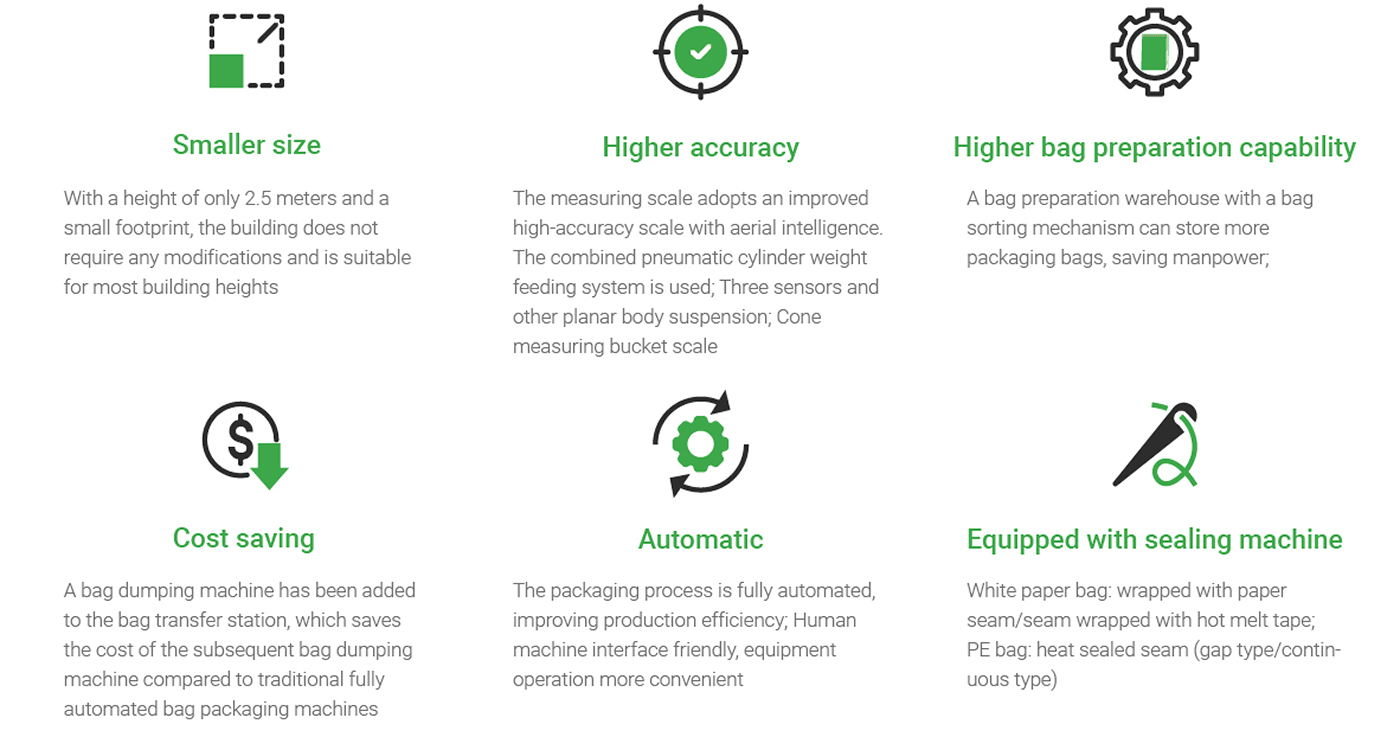

Product Features

Parameters

|

Model

|

Material to be packaged

|

Weighing range

|

Packing speed | Packing accuracy | Power |

|

|

Pellets |

20-25kg/bag

|

200bag/h | ±0.1% | 2kw |

|

ACGS-DA(R)

|

Gas consumption

|

Weight

|

Working condition

|

Air pressure

|

Noise

|

|

|

18 m ³ /h |

1.5-2t

|

0-40℃

|

0.5-0.7MPa

|

≤ 75db |

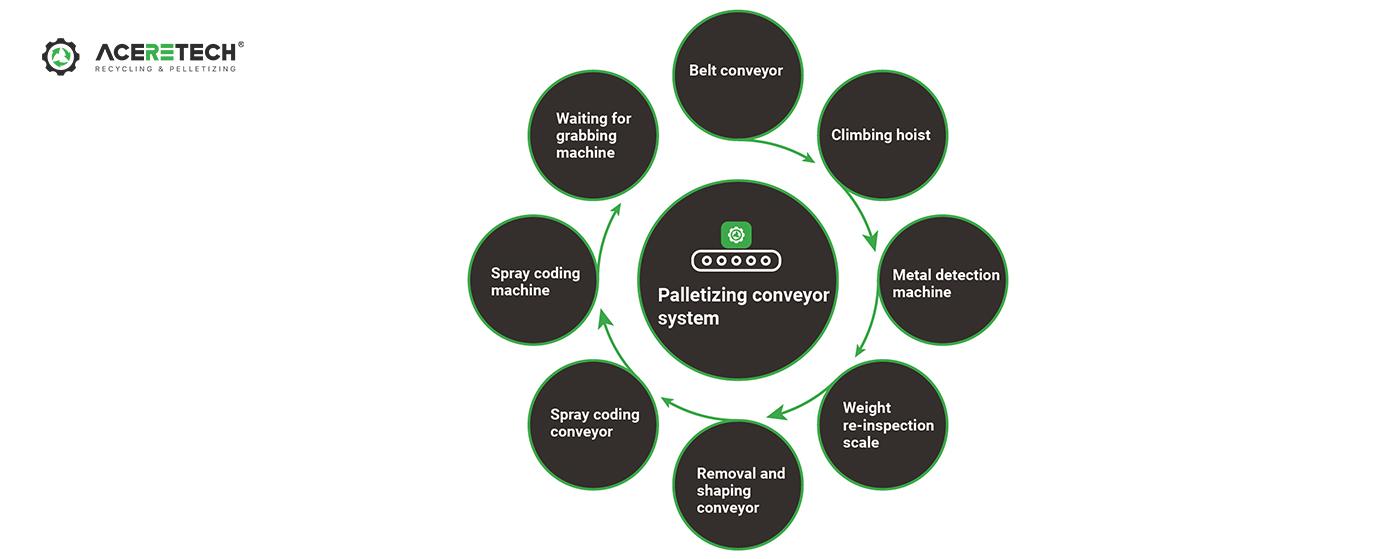

Palletizing Conveyor System

After the sealed package is poured onto the receiving belt conveyor, the climbing conveyor lifts the package to the required height for robot palletizing and grabbing. It then enters the weight recheck scale to recheck the accuracy. Products with unqualified accuracy are removed by the removal and shaping machine, while qualified products are shaken and shaped by the vibration shaping and pressing conveyor. After shaping is completed, the package is transported to the position of the coding

conveyor for coding. After coding is completed, the package is transported to the grabbing conveyor and waiting for the robot to grasp the palletizing.

Palletizing Conveyor System Including

Stacking Robot System

* Adopting ergonomic design, comfortable and lightweight operation ;

* Display in both Chinese and English, with a user-friendly interface ;

* Dual safety switch, fully ensuring the safety of personnel operation ;

* Equipped with USB interface, supporting import/ export of teaching programs ;

Tray Storage System

The pallet storage warehouse transports empty pallets to the palletizing conveyor through the empty pallet conveyor and waits for the robot to palletize them. When there are material packages on the grabbing conveyor, the robot starts palletizing and stacks them onto the pallet of the palletizing conveyor; Complete the palletizing operation according to the prescribed grouping mode, and the full stack of material packages will enter the online winding machine for automatic film wrapping, and then be covered with film on the top by the top covering machine; The wrapped products enter the full stack fork picking conveyor and wait for the forklift to pick them up.