R-PET Food Grade Sheet Extrusion Line

ACERETECH as professional manufacturer of plastic recycling machine, we can provide R-PET food grade Turn-key solution for waste PET bottle recycling from washing, extru-sion and pelletizing. Even after washed quality PET bottle flakes can one-step make R-PET food grade sheet.

Recycling & Material

R-PET sheet is a common plastic made of polyethylene glycol (PET), due to its high transparency, heat resistance, impact resistance, and ease of processing and molding,sheets are widely used in the food packaging industry, it can be also used in bottles, fibers. industrial applications, electronic products, etc.

At present, the global R-PET sheet market has reached billions of dollars, mainly driven by applications such as food packaging, fiber, and bottles. The global R-PET bottle market is expected to reach around 140 bilion dollars by 2025, with an annual compound growth rate of 7.5%, bringing huge market opportunities to the R-PET sheet industry.In terms of R-PET food grade sheet extrusion technology, new technologies and processes are constantly emerging, including multiple innovative technologies such as reactive extrusion and co-extrusion, which have continuously improved the production efficiencyand performance of R-PET food grade sheets.

ACERETECH as professional manufacturer of plastic recycling machine, we can provide R-PET food grade Turn-key solution for waste PET bottle recycling from washing, extru-sion and pelletizing. Even after washed quality PET bottle flakes can one-step make R-PET food grade sheet.

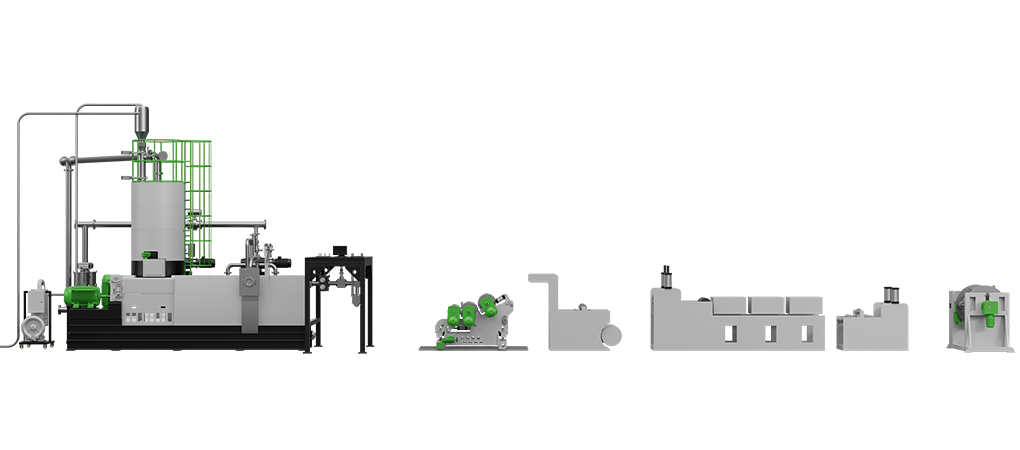

Technical Process :

Vacuum feeder -> Reaction chamber-> ACS single screw extruder-> Backflush screenchanger -> Melt pump -> Melt viscosity online measurement system -> T-die -> Three-rollercalender -> Edge trimming device -> Silicone oil coating device -> Haul off unit -Winder.

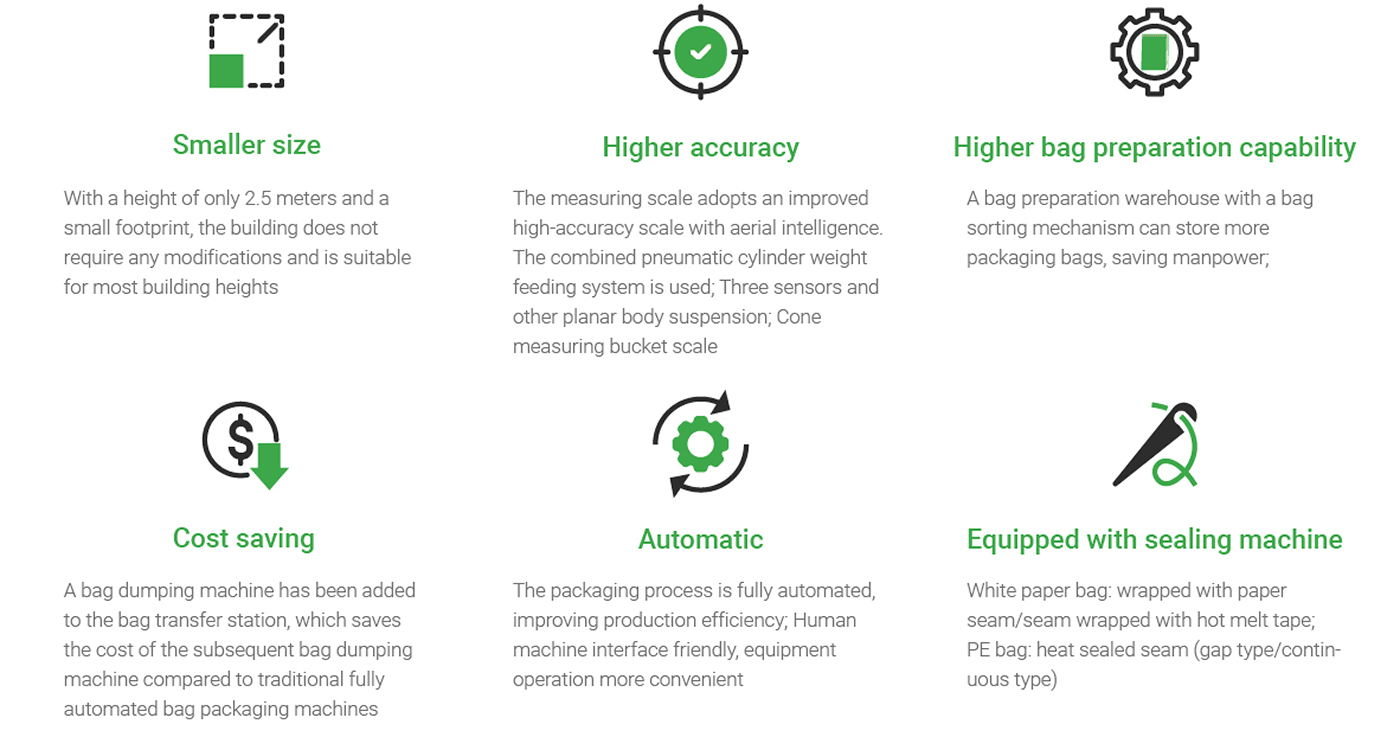

Product Features

Parameters

|

Model

|

Material to be packaged

|

Weighing range

|

Packing speed | Packing accuracy | Power |

|

|

Pellets |

20-25kg/bag

|

200bag/h | ±0.1% | 2kw |

|

ACGS-DA(R)

|

Gas consumption

|

Weight

|

Working condition

|

Air pressure

|

Noise

|

|

|

18 m ³ /h |

1.5-2t

|

0-40℃

|

0.5-0.7MPa

|

≤ 75db |

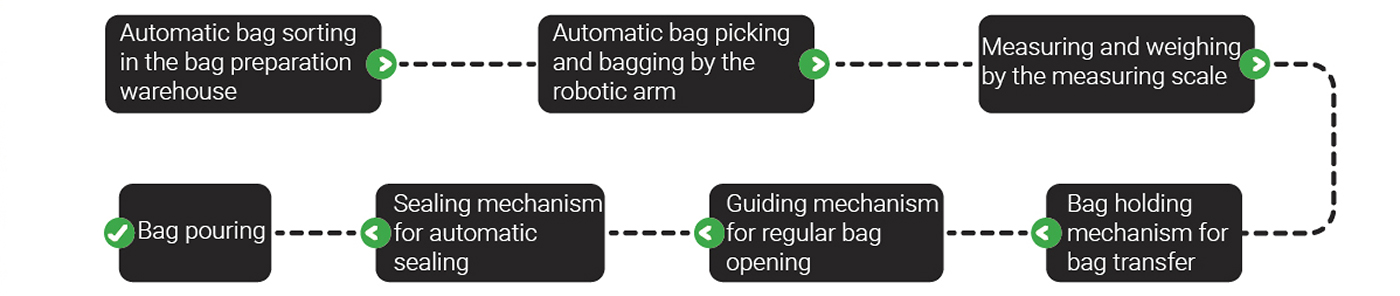

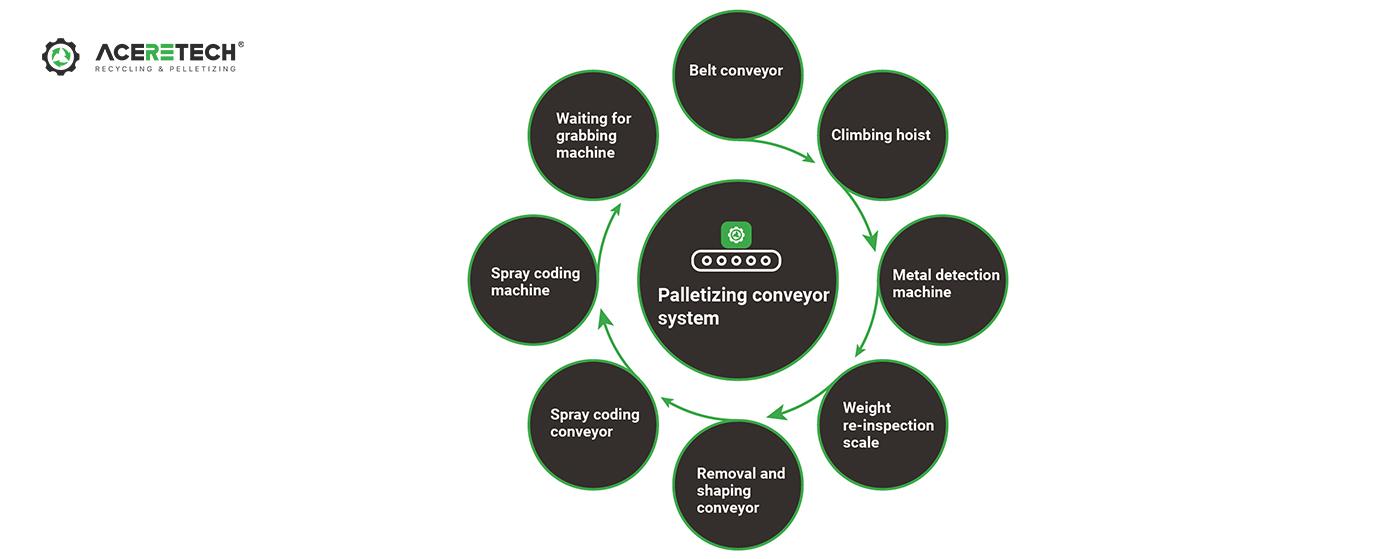

Palletizing Conveyor System

After the sealed package is poured onto the receiving belt conveyor, the climbing conveyor lifts the package to the required height for robot palletizing and grabbing. It then enters the weight recheck scale to recheck the accuracy. Products with unqualified accuracy are removed by the removal and shaping machine, while qualified products are shaken and shaped by the vibration shaping and pressing conveyor. After shaping is completed, the package is transported to the position of the coding

conveyor for coding. After coding is completed, the package is transported to the grabbing conveyor and waiting for the robot to grasp the palletizing.

Palletizing Conveyor System Including

Stacking Robot System

* Adopting ergonomic design, comfortable and lightweight operation ;

* Display in both Chinese and English, with a user-friendly interface ;

* Dual safety switch, fully ensuring the safety of personnel operation ;

* Equipped with USB interface, supporting import/ export of teaching programs ;

Tray Storage System

The pallet storage warehouse transports empty pallets to the palletizing conveyor through the empty pallet conveyor and waits for the robot to palletize them. When there are material packages on the grabbing conveyor, the robot starts palletizing and stacks them onto the pallet of the palletizing conveyor; Complete the palletizing operation according to the prescribed grouping mode, and the full stack of material packages will enter the online winding machine for automatic film wrapping, and then be covered with film on the top by the top covering machine; The wrapped products enter the full stack fork picking conveyor and wait for the forklift to pick them up.