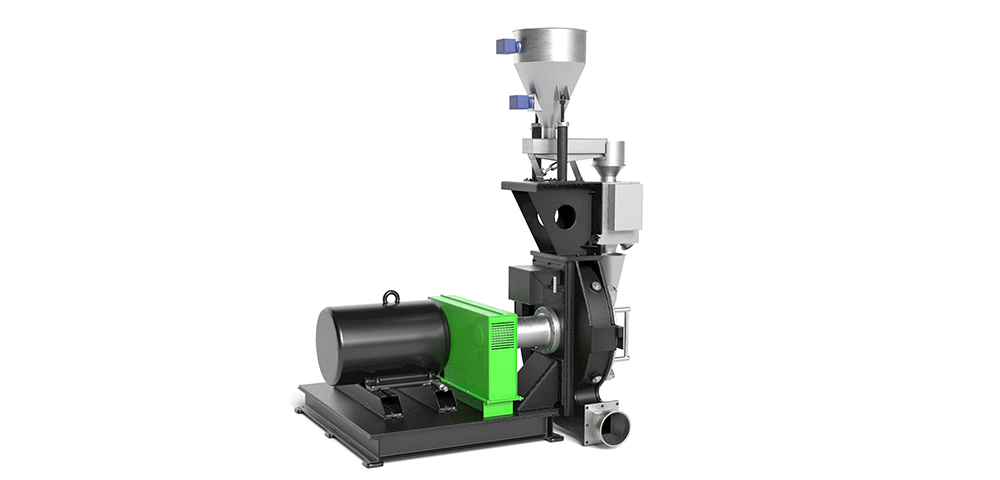

PM800塑料再利用碳钢粉碎机

该粉碎机适用于需要粉状产品的半硬质、脆性和抗冲击材料的粉碎。

尺寸为 6-8 毫米的颗粒通过振动筛送入旋转的高速锯齿圆盘中,以生产所需的 300-1000 微米范围内的粉末产品,最终尺寸由可调节的圆盘间距决定。 通常用于撕碎 LDPE、HDPE、UPVC、PC 和各种其他塑料。

回收与材料

优点

01. 维护成本低

设备结构简单,易损件少,维护保养方便,降低维修费用。

02. 应用范围广泛

可处理多种塑料材质,满足不同客户需求。

03. 磨粉精度高

粉末细腻均匀,提高产品质量,满足高端市场需求。

04. 安全可靠

全封闭式设计,防止粉尘泄露,保障生产安全。

05. 自动化程度高

实现自动上料、磨粉、出料,减少人工干预。

06. 占地面积小

紧凑型设计,节省车间空间,降低厂房投资。

产品参数

| 型号 |

PM800

| ||

| 原材料 | H-PVC-Profile ,H-PVC-Pine ,LDPE(MFI70) 等 |

最终产品和产能 |

3×380V,50Hz; 控制电流 220V, 50Hz

|

|

电流 |

3×380V,50Hz; 控制电流 220V, 50Hz

|

Rotor speed

|

3240 rmp

|

|

PE

|

400-500 kg/h

|

Disc diameter

|

800 mm

|

|

Profile- H-PVC

|

800-1000 kg/h

|

Tooth grooves

|

2.79

|

|

Pipe- H-PVC

|

900-1100 kg/h

|

Drive motor

|

90 kw

|

PM500 PVC Pulverizer Machine for Plastic Recycling

Applications

The pulverizer is suitable for the pulverization of semi-rigid, brittle and impact resistant materials that require powdered products.

Particles with a size of 6-8 mm are fed through a vibrating screen into a rotating high-speed sawtooth disc to produce a powder product in the desired 300-1000 micron range, with the final size determined by adjustable disc spacing. Typically used for shredding LDPE, HDPE, UPVC, PC and various other plastics.

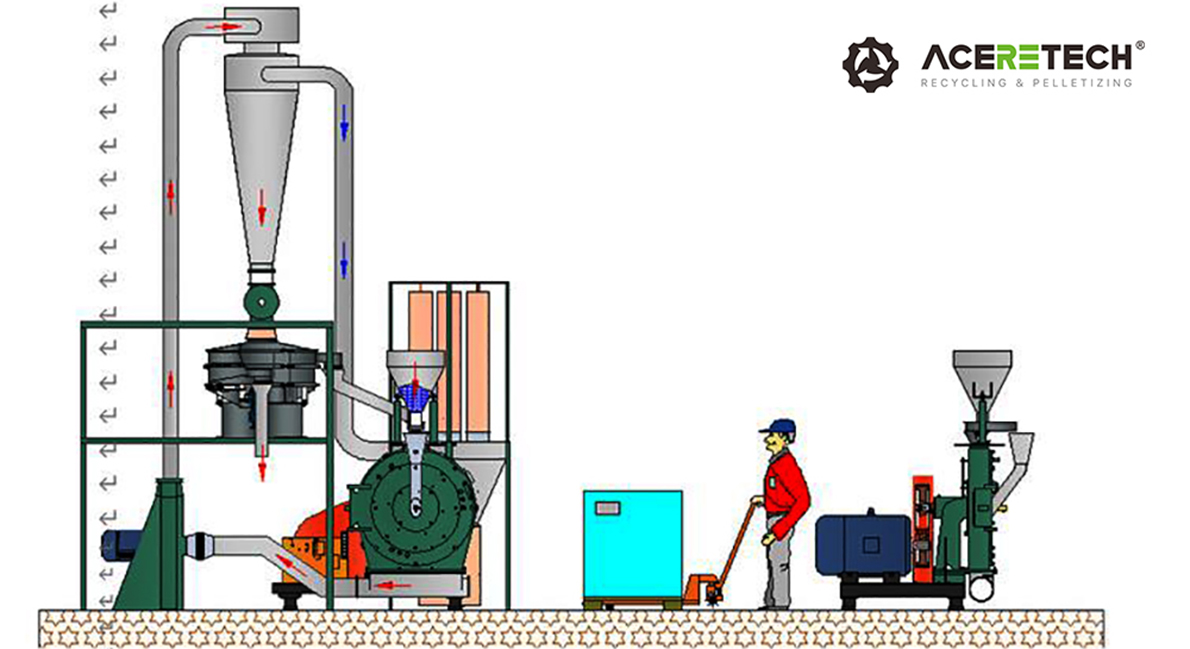

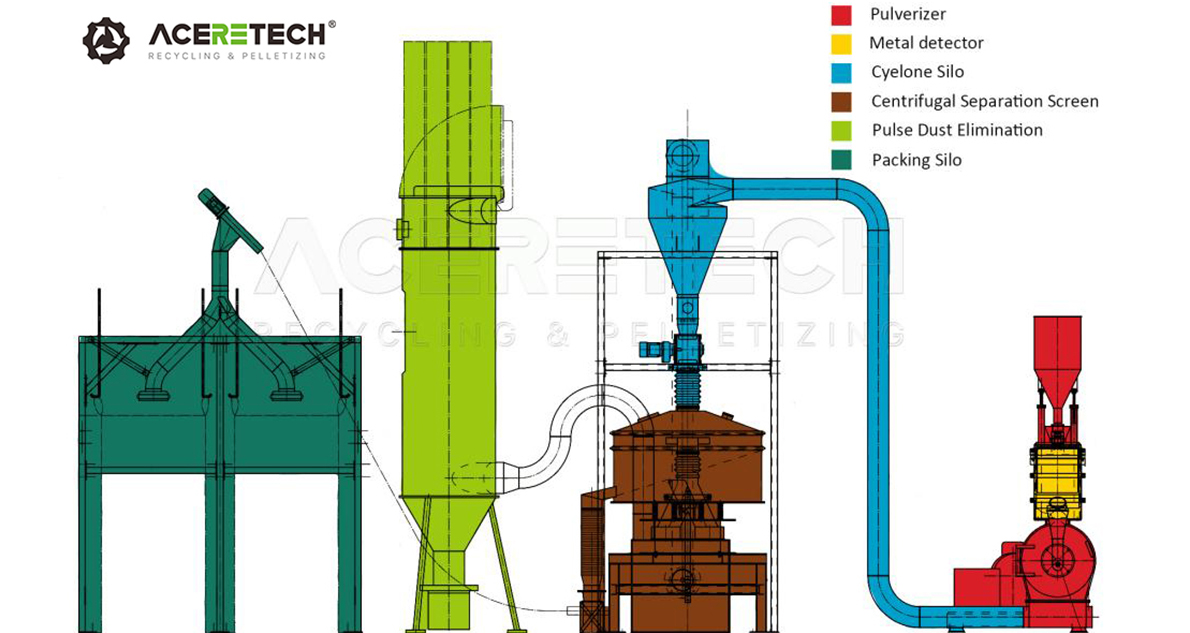

Design

The PM800 pulverizer series are ultra-high output units that can be equipped with automatic temperature control. The material to be pulverized is fed centrally between fixed and high-speed rotating pulverizing discs, which have a centrifugal effect, allowing the material to pass through the processing zone and then be pneumatically discharged from the machine.

Advantages

* Long service life of discs between regrindings.

* Replace and adjust discs quickly and easily.

* Low residence time means low thermal stress on the process material.

* High throughput capabilities.

* Cost effective operation.

Technical features

* Dosing channel/Vibratory feeder

* The channel width is 100 - 250mm, and the storage container is appr. 50-100 lit.

* The feeding is regulated and consumed by the high current controller monitoring the pulverizer motor, including the mounting bracket and control device.

Pulverizer housing

* Disc pulverizer with a fixed and a high-speed toothed disc with precision bearings.

* Material is fed through the opening in the center of the fixed disc.

* The size of the particles depends on the surface structure of the teeth and the adjustable distance between the tooth discs. The cutting clearance can be checked through the inspection hole in the housing. This makes it easy to adjust from the outside of the device using a feeler gauge. The device operates without a screen.

* The machine housing is made of fracture resistant welded steel. The hinged housing door with fixed toothed disc opens to the side for cleaning and replacing the toothed disc.

* The grinding chamber is well designed with a small cross-section and a flat, almost vertically mounted grinding disc.

* The material is clamped and reduced immediately after entering the grinding chamber.

Pulverizer discs

* Specially designed discs and high-speed peripheral running speed ensure efficient impact reduction under low power requirements.

* Pulverizer disc diameter 800mm

Temperature control

The enhanced cooling device for automatically controlling the temperature includes a nozzle for spraying in cooling water, regulating control devices, solenoid valves, thermostats, an automatic control device and a material feeding switch.

Drive and mounting frame

A flat steel structure is used to install the pulverizer and suction box. The drive motor includes "V" belt drive and belt guard. The frame is equipped with pre installed anti vibration pads.

Safety devices

Integrated operational safety device to prevent entry until the rotor is completely stationary.

Pulverizer machine

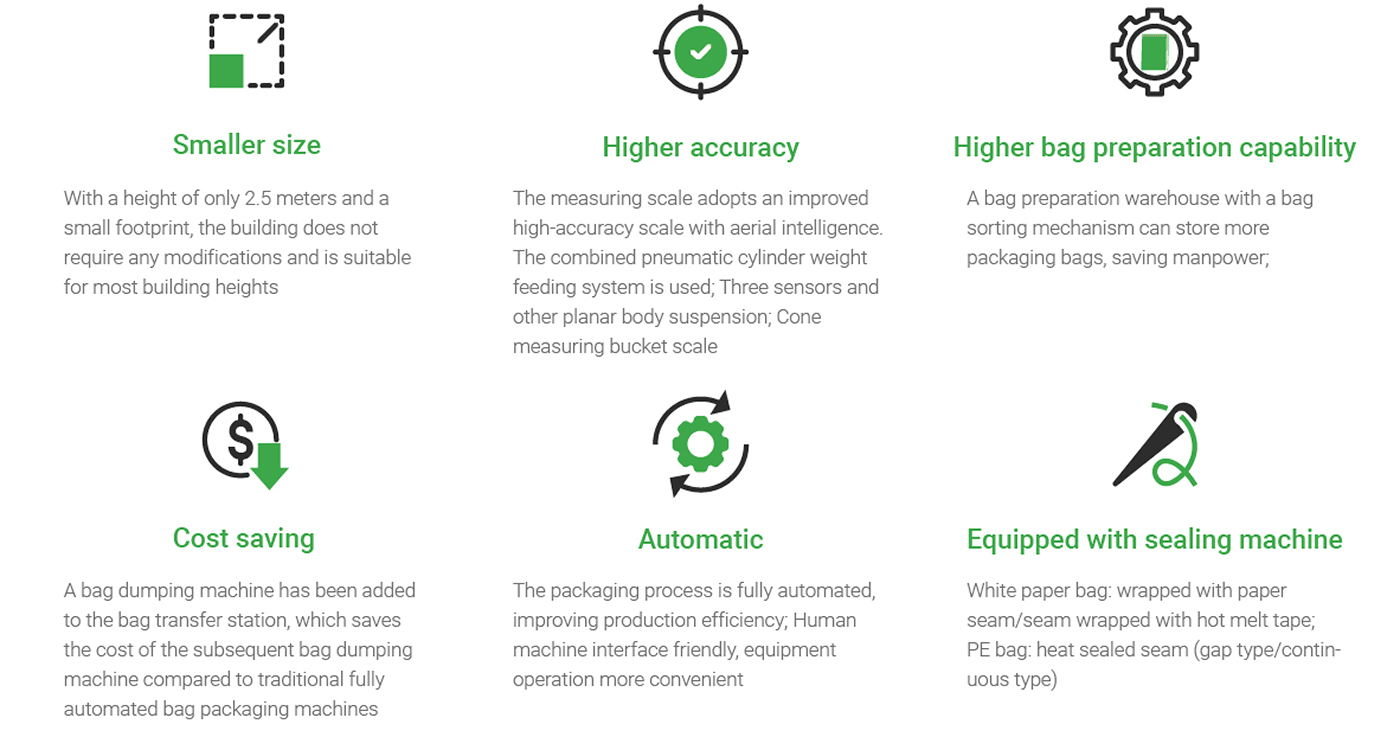

产品特点

产品参数

|

型号 |

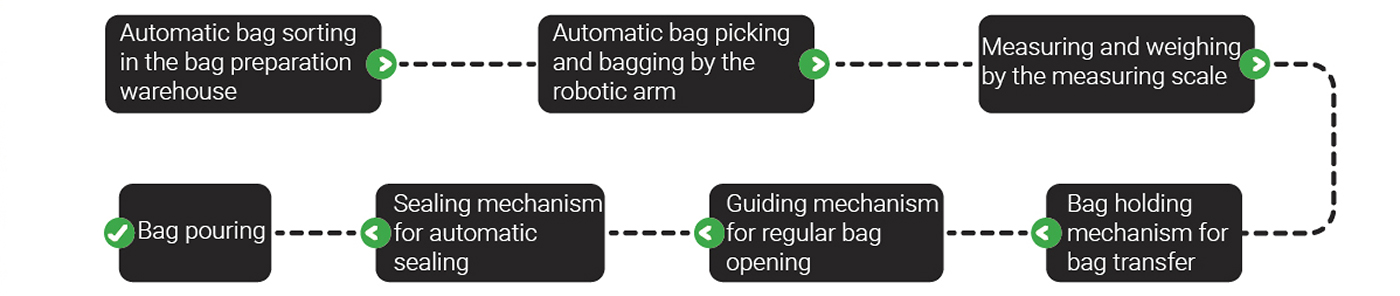

需要包装的材料

|

称重范围

|

包装速度 | 包装精度 | 功率 |

|

|

颗粒 |

20-25kg/bag

|

200bag/h | ±0.1% | 2kw |

|

ACGS-DA(R)

|

气体消耗量

|

重量

|

环境温度 |

气压

|

噪音

|

|

|

18 m ³ /h |

1.5-2t

|

0-40℃

|

0.5-0.7MPa

|

≤ 75db |

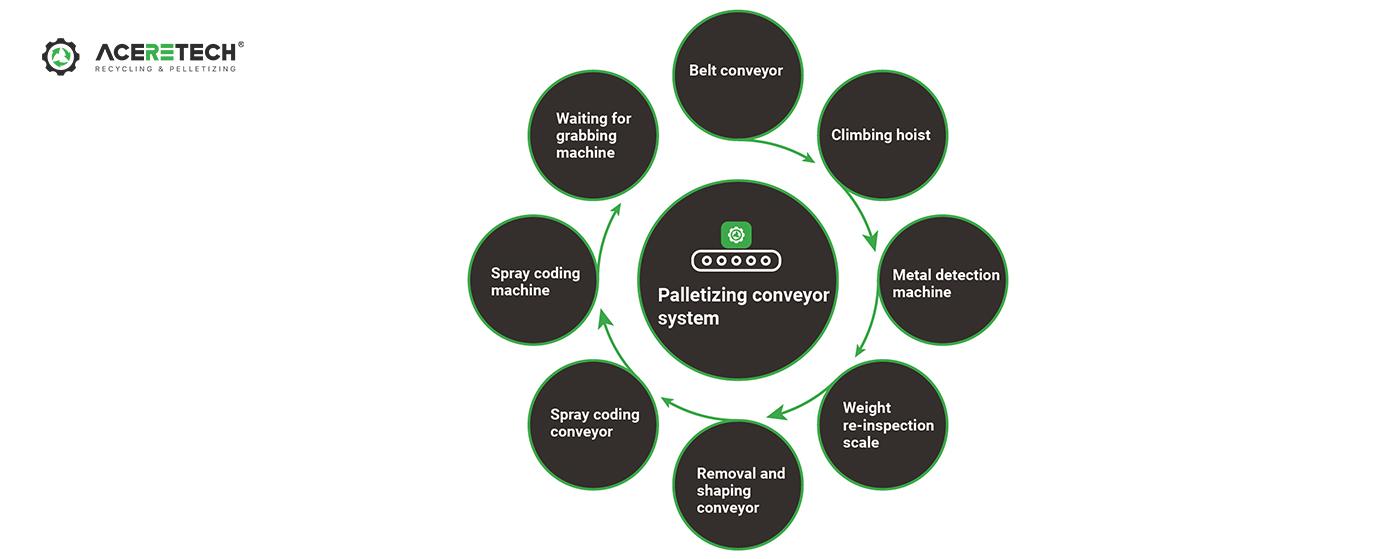

码垛输送系统

封好的包装物倒在接料皮带机上后,爬坡输送机将包装物提升到所需高度,供机器人码垛抓取,然后进入重量复检秤进行精度复检,精度不合格的产品由剔除整形机剔除,合格产品由振动整形压实输送机进行振动整形。整形完成后,包装物被输送到编码输送机的位置进行编码,编码完成后,包装物被输送到抓取输送机上,等待机器人抓取码垛。

码垛输送系统包括

码垛机器人系统

* 采用人体工程学设计,操作舒适轻便;

* 中英文显示,界面友好;

* 双重安全开关,充分保证人员操作安全;

* 配备 USB 接口,支持教学程序导入/导出;

托盘存储系统

托盘存储仓通过空托盘输送机将空托盘输送到码垛输送机上,等待机器人码垛。当抓取输送机上有物料包时,机器人开始码垛,并将其码垛到码垛输送机的托盘上;按照规定的分组方式完成码垛作业,满堆的物料包装将进入在线缠绕机进行自动裹膜,再由覆顶机在顶部盖膜;裹好后的产品进入满堆叉取输送机,等待叉车取走。