In the field of plastic recycling, the recycling and reuse of food-grade PET bottles is a highly technically demanding job. ACERETECH, as an industry-leading plastic recycling equipment manufacturer, customized a set of 2T/H PET bottle recycling, shredding, crushing and washing production lines according to customer needs, which are specially designed for food-grade PET bottles to ensure the efficiency of the recycling process and the purity of product quality.

Introduction to PET Bottles

PET bottles, namely polyethylene terephthalate bottles, are widely used in beverage, food and other packaging fields due to their lightness, transparency and pressure resistance. However, recycling PET bottles requires professional equipment and technology to remove contaminants such as labels, glue, ink, etc. on the bottles to ensure the safety and applicability of recycled PET materials.

Belt conveyor with metal detection: The recycled PET bottles first pass through a belt conveyor with metal detection to automatically remove metal impurities.

Debaler: Unpack the packaged PET bottles for subsequent processing.

Trommel: Preliminary removal of large impurities from PET bottles.

Label remover: Specially designed to remove labels from PET bottles.

Pre-washer: Preliminary cleaning after screw feeding to remove surface dirt.

Bounce screen: Further screening to remove fine impurities.

Manual sorting roller: Workers perform manual sorting at this stage to ensure that impurities are completely removed.

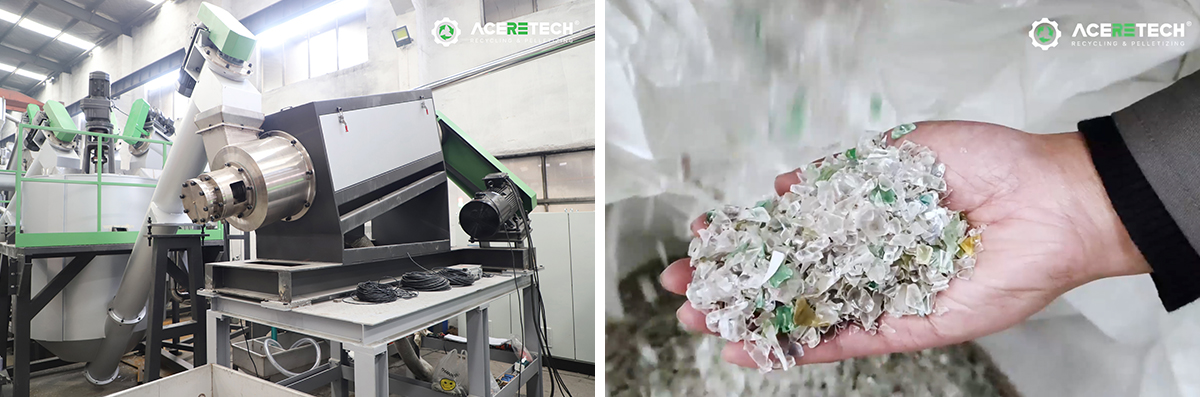

Two sets of GH crusher: Shred PET bottles to prepare for washing.

Separation floating tank: Separates light impurities using the flotation principle.

Bottle cap lifting screw: Specially processes bottle caps to improve recycling efficiency.

Centrifugal dryer: Removes moisture from PET fragments.

Label separator: Further ensures complete label removal.

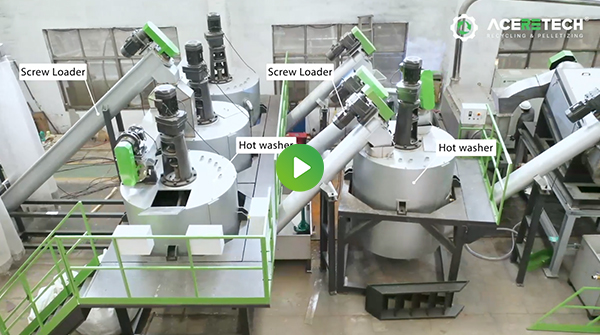

4 sets of hot washers: High-temperature washing to effectively remove glue and ink.

Centrifugal dehydrator: dehydrate again to ensure that the PET fragments are dry.

2 Sets of separation flotation tanks: further purify the PET fragments.

Pipeline drying: through the pipeline dryer, the PET fragments are made to reach the best drying state.

Silo: finally obtain clean and uniform PET bottle flakes.

Equipment advantages

The PET recycling equipment produced by ACERETECH is stable and durable, with a high degree of automation. It is the only company in China that has obtained the US FDA certification. It also has multiple certificates such as CE, ISO, CSA, etc., which can meet the requirements of food-grade contact materials. The washed bottle flakes can completely remove labels, glue, ink and impurities in the bottle to ensure that there is no contamination to the recycled PET materials.

Customer Service

ACERETECH provides on-site installation, maintenance, commissioning and online guidance services, which can quickly respond to and solve customer problems. Many customers around the world have used PET recycling equipment produced by ACERETECH, and it has been put into production normally. Customers are highly satisfied with our equipment.

Conclusion

ACERETECH's PET bottle-to-bottle recycling shredding, crushing and washing solution not only improves the efficiency of PET bottle recycling, but also ensures the safety and quality of recycled PET materials, setting a new benchmark for the plastic recycling industry. We will continue to be committed to technological innovation, provide customers with better services, and jointly promote the green development of the plastic recycling industry.

Click the link below to view the food grade PET bottle to bottle recycling shredding and washing workshop test machine video.