I. Definition and recycling significance of TPU

Thermoplastic polyurethane (TPU for short) is an environmentally friendly material with excellent properties such as high strength, high elasticity, wear resistance, oil resistance, and hydrolysis resistance. It is widely used in shoe materials, films, wires, pipes, automotive accessories and other fields. However, in the production process, TPU will produce a large amount of scraps and waste. Recycling and reusing these wastes can not only reduce corporate costs, but also reduce environmental pollution, which is of great significance.

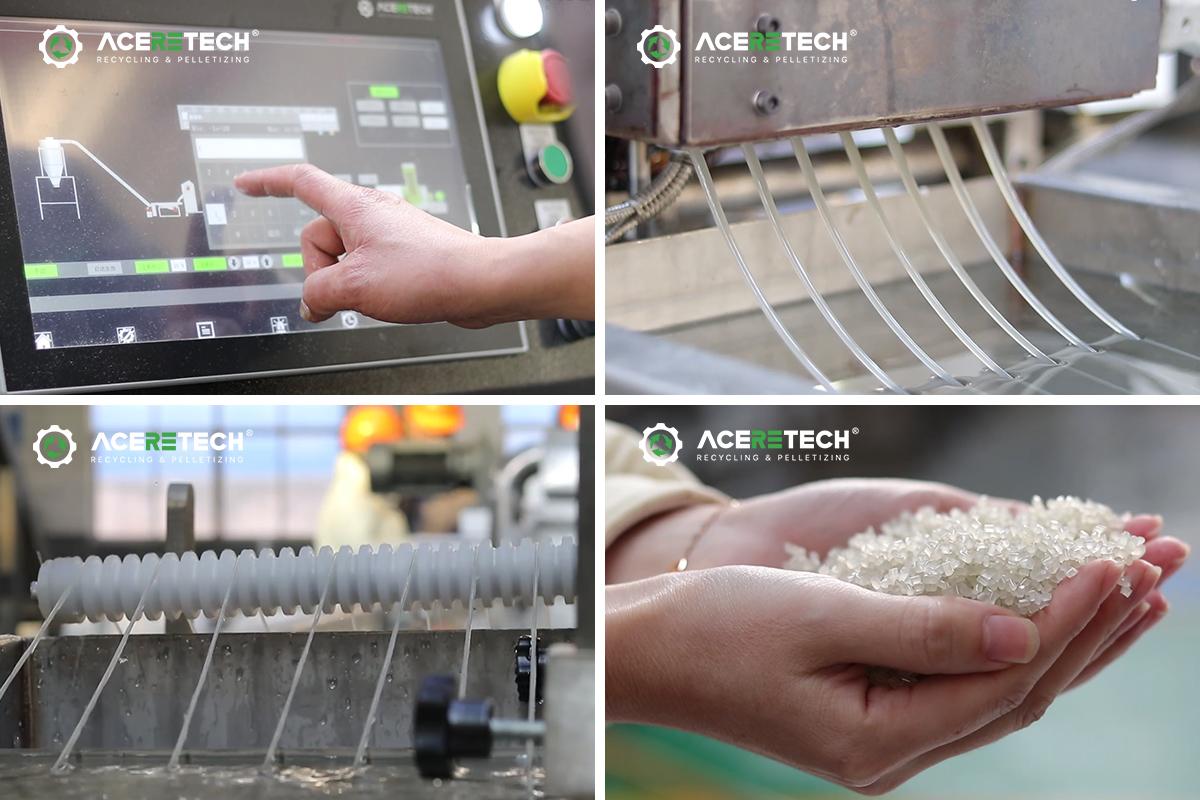

ACERETECH focuses on the research and development and production of plastic recycling equipment, and provides a complete solution for TPU in-plant shredding and pelletizing recycling-ASP crushing, plasticizing, extrusion, and pelletizing integrated recycling machine. The equipment has the following characteristics:

High efficiency and stability: The ASP integrated recycling machine adopts advanced technology to realize the integration of crushing, plasticizing, extrusion, and pelletizing, with high production efficiency and stable operation.

Intelligent control system: The equipment is equipped with an intelligent control system, which can automatically adjust the operating parameters according to the characteristics of different materials to ensure product quality.

Strip pelletizing: The strip pelletizing technology is used to make the particles regular in shape and uniform in size, thereby improving the particle quality.

High particle quality: The TPU particles processed by the ASP integrated recycling machine have performance close to that of the original materials and can be widely used in various fields.

III. TPU factory tearing and granulation recycling process

Collection: Collect the TPU scraps and waste generated during the production process.

Crushing: The TPU waste is crushed into smaller particles by the ASP crusher.

Plasticization: The crushed TPU particles enter the plasticizer and are plasticized at high temperature to make the material reach a molten state.

Extrusion: The molten TPU material passes through the screw extruder to form a uniform strip material.

Pelletizing: The strip material enters the plletizer and is cut into uniform pellets by a pelletizer.

Cooling: The finished TPU particles pass through the cooling water tank and are cooled and solidified.

Drying: The cooled particles are dried to remove moisture and ensure the quality of the particles.

IV. Conclusion

Using ACERETECH ASP crushing, plasticizing, extruding and pelletizing integrated recycling machine to realize TPU shredding and pelletizing recycling in the factory can not only reduce the production cost of enterprises, improve resource utilization, but also reduce environmental pollution and promote the green development of the global plastic recycling industry. With the continuous improvement of environmental awareness, the market prospects for TPU recycling and reuse are broad. ACERETECH will continue to innovate and provide more high-quality equipment for the plastic recycling industry.

Click the link below to watch the factory workshop test machine