With the rapid development of the economy, the usage of plastic products has been increasing year by year, especially PE (polyethylene) and PP (polypropylene) pipes, which are widely used in construction, water supply and drainage, gas and other fields. However, these plastic products generate a large amount of waste during use, causing serious environmental pollution. How to achieve the resource utilization of waste plastics has become an urgent problem to be solved. The technology of tearing, crushing, and granulating PE and PP pipes provides a powerful way to solve this problem.

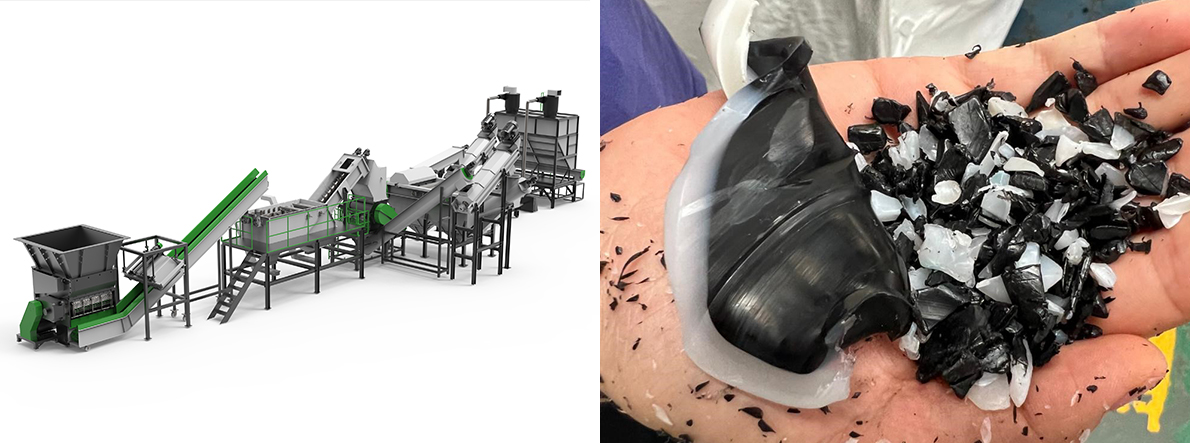

Process flow of shredding, crushing, and granulation of PE and PP pipes.

Shredding: Scrap PE and PP pipes into small pieces through a shredder for further processing.

Crushing: The shredded waste plastic is crushed through a crusher to achieve a certain particle size requirement, preparing for subsequent granulation.

Cleaning: Clean the crushed plastic flakes to remove impurities and improve the purity of the plastic flakes.

Granulation: The cleaned plastic flakes are granulated using a granulator to form plastic granules that meet production requirements. Dry the plastic granules after granulation to ensure their moisture content meets the specified requirements and ensure the quality of plastic products. Pack the dried plastic granules for easy storage and transportation.