1. Introduction to PP non-woven fabric and PP fiber

PP non-woven fabric, also known as polypropylene non-woven fabric, is a non-woven fabric made of short polypropylene (PP) fibers by thermal bonding or other methods. It is light, soft, breathable, waterproof, and has high tensile strength. It is widely used in medical, health, construction, agriculture, packaging and other fields. PP fiber, which is the abbreviation of polypropylene fiber, has good chemical resistance, heat resistance and electrical insulation. It is a common raw material for manufacturing non-woven fabrics, ropes, carpets and other products.

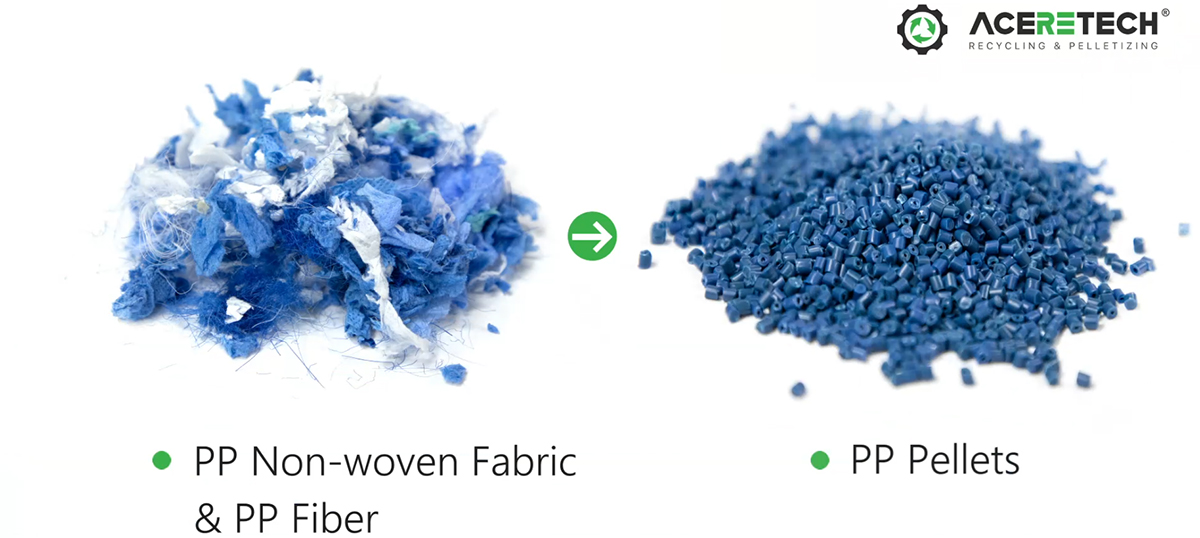

With the widespread application of PP non-woven fabrics and PP fibers in various fields, the recycling and reuse of their waste has become an important issue of environmental protection and resource circulation.

2. ACERETECH LS single-shaft shredder configuration

According to the characteristics of PP non-woven fabrics and PP fibers, ACERETECH has configured LS single-shaft shredders for customers. The equipment has the following features:

LS series single-shaft light shredders: designed for waste plastic products with small volume and small wall thickness, such as: pipes with small volume and wall thickness, waste hollow pipes, plates, profiles in plastic production and manufacturing, and blocks and waste in injection molding.

Uniform size reduction: LS single-shaft shredders can evenly reduce the size of PP non-woven fabrics, making the recycling process easier and more efficient.

Efficient shredding: The equipment has a compact design and high shredding efficiency, and is suitable for processing PP non-woven fabrics and fiber waste of various sizes.

3. ACS-PRO granulator application

In the granulation stage after shredding PP non-woven fabrics and PP fibers, ACERETECH uses ACS-PRO granulators, which have the following advantages:

Intelligent control system: ACS-PRO granulators are equipped with advanced intelligent control systems to ensure the automation and precise control of the production process.

Strand pelletizing: The strand pelletizing technology can cut the shredded PP material into uniform, high-quality pellets.

Air-cooled drying: During the pelletizing process, the air-cooled drying system effectively ensures the dryness and quality of the pellets.

European electrical equipment: The ACS-PRO pelletizer uses European standard electrical equipment to ensure the efficient, stable, environmentally friendly and safe operation of the equipment.

4. Meeting customer needs

ACERETECH's LS single-shaft shredder and ACS-PRO pelletizer combination solution can fully meet the following needs of customers in the recycling and pelletizing process of PP non-woven fabrics and PP fibers:

Efficient: high-speed shredding and pelletizing to improve production efficiency.

Stable: stable equipment operation, reduced downtime, and guaranteed continuous production.

Environmental protection: reduce environmental pollution through recycling and reuse.

Safety: use high-standard electrical equipment to ensure production safety.

5. Conclusion

PP non-woven fabrics and PP fibers shredding and pelletizing technology not only contributes to the recycling of resources, but also effectively reduces environmental pollution. ACERETECH's LS single-shaft shredder and ACS-PRO granulator provide a complete solution for the recycling of PP materials, meeting customers' needs for efficient, stable, environmentally friendly and safe production. With the continuous improvement of environmental awareness, this technology will play a greater role in the plastic recycling industry.

Click the link below to view the factory workshop test video.

PP Non-woven Fabric And PP Fiber Shredding And Granulation Recycling

2025/02/12

in Applications