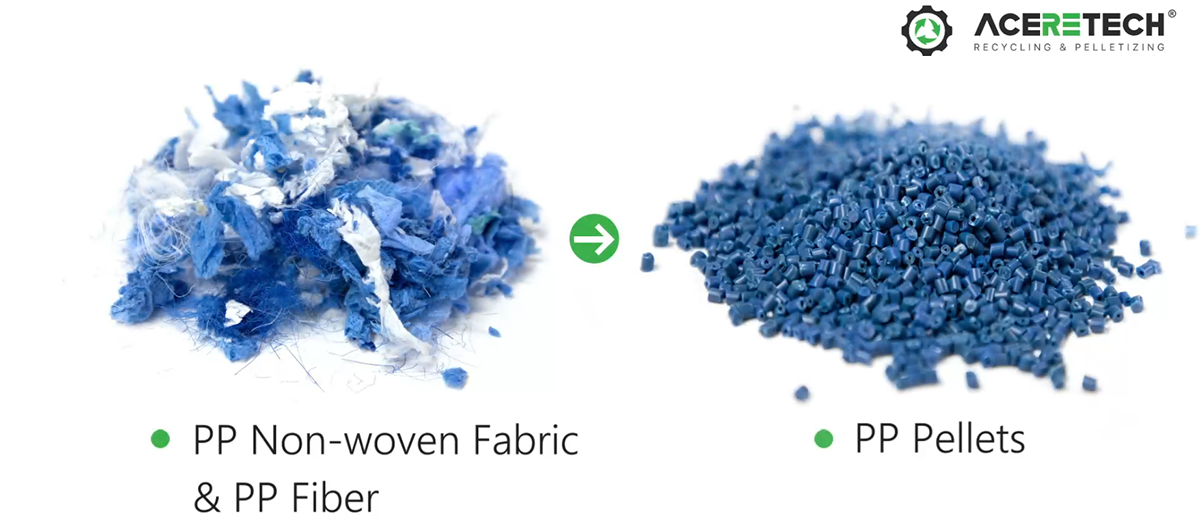

1. Introduction to PP non-woven fabric

PP non-woven fabric, full name polypropylene non-woven fabric, is an environmentally friendly material with excellent chemical resistance, heat resistance, electrical insulation and high strength. It is widely used in medical and health, home decoration, agricultural covering, industrial protection and other fields. With the continuous improvement of my country's environmental awareness, PP non-woven fabrics are more and more widely used in life. However, the resulting problem of waste PP non-woven fabric treatment is also becoming increasingly prominent. How to achieve the recycling and reuse of waste PP non-woven fabrics has become an important issue in the current environmental protection cause.

In response to the problem of PP non-woven fabric recycling and granulation, ACERETECH recommends an efficient and energy-saving ACS-H plastic recycling granulator to customers. The equipment has the following highlights:

Pellet barrel capacity: 300L, to meet large-scale production needs and improve production efficiency.

Extrusion screw diameter: 80mm, to ensure that the material is fully plasticized during the extrusion process and improve product quality.

Adopting strand pelletizing technology, the particles are uniform and convenient for subsequent applications.

3. Application of ACS-H plastic recycling granulator in PP non-woven fabric recycling

Recycling process

After pre-treatment such as washing, crushing and drying, the waste PP non-woven fabric enters the ACS-H plastic recycling granulator for granulation.

Granulation process

(1) Pre-plasticization: The material is subjected to high temperature and shearing in the barrel to achieve pre-plasticization.

(2) Plasticization: The material is further plasticized under the action of the extrusion screw to achieve the required viscosity.

(3) Strip drawing: The plasticized material is extruded into strips and enters the cooling water tank for cooling.

(4) Pelletizing: The cooled strip material is cut into high-quality pellets of uniform size by the pelletizer.

Product advantages

(1) High recovery rate: The recovery rate of waste PP non-woven fabric by ACS-H plastic recycling granulator can reach more than 95%.

(2) Excellent product quality: The strip cutting technology is adopted, and the pellets are uniform, meeting the needs of downstream customers.

(3) Energy saving and environmental protection: During the operation of the equipment, the energy consumption is low and there is no pollution emission.

If you want to learn how to recycle PP non-wovens, you can view the detailed trial video through the link below to understand the operation of the equipment.