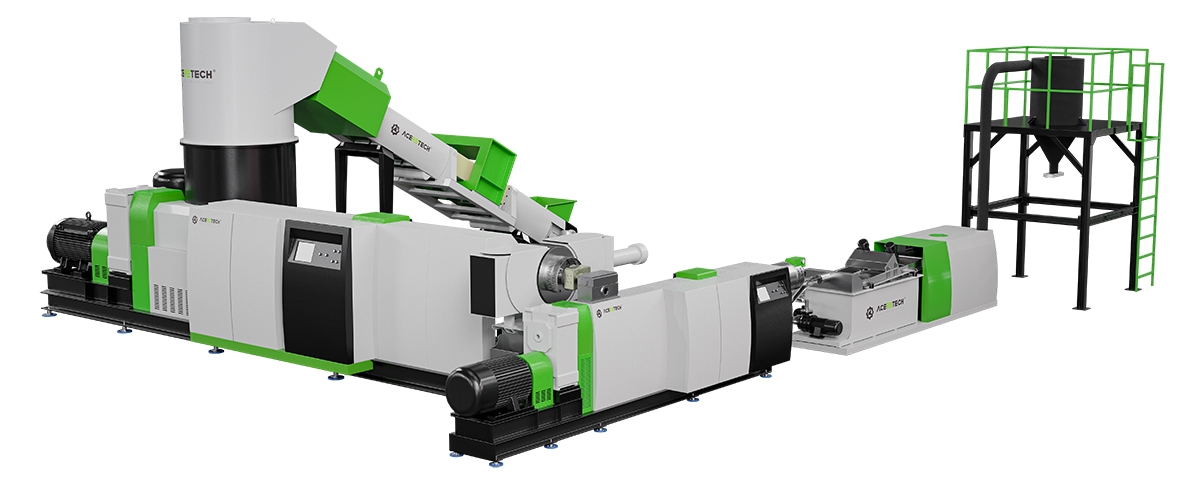

Raw material: PP woven bag

Machine process as below:

1. Belt conveyor to feed material into compactor, the speed of belt conveyor is automatic controlled based on how full the compactor room is

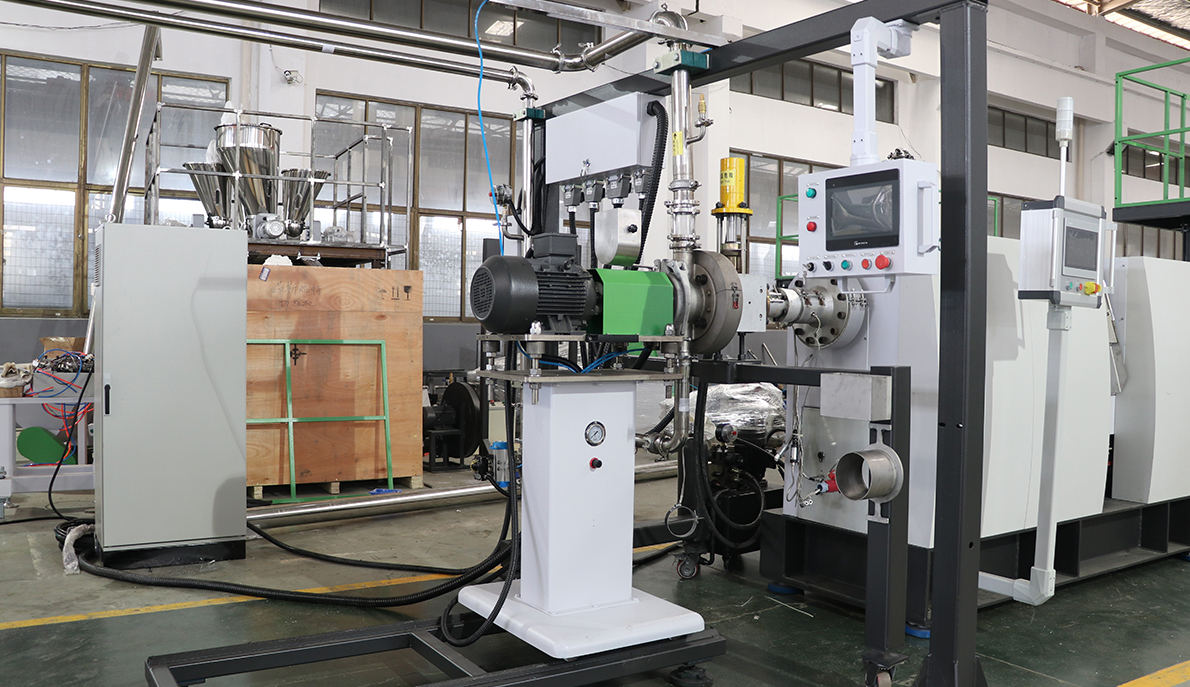

2. Compactor equipped with sliding gate, inverter, dust&moisture exhausting device which can realize both soft and rigid flakes recycle in one machine

3. 1st stage extruder with double vacuum degassing system

4. Automatic slag discharge type screen changer, laser filter.

5. 2nd stage extruder

6. Piston type screen changer, big filtration area for fine filtration to present high quality pellets

7. Water cooling strands pelletizing system consists of sink, pelletizer, vibration dryer, blower and silo. Also can use underwater cutter.

8. Capacity online monitoring & Quantitative weighing system

ACERETECH main product compacting and pelletizing system combines crush, compacts, extrusion and pelletizing in one system.

Intellogent control system:

One button start, one button stop, emergency stop

Remote control and data transmission:

Controlling and monitoring function in LAN net

Protection system:

Life safety protection, plasctic properties protection, protection from over-heat in the compactor