For many years, Aceretech has done several PET projects, both washing and pelletizing.

For example, in 2017, we delivered a PET flake pelletizing project to Guatemala, the client recycled PET, washed it, pelletized it, and then manufactured their products with a low percentage of recovered resins.

With many years, the customer has a very simple wash, and then can reuse the PET resins in their products. Then, due to the global trend, the client invests in a modern, more sophisticated PET washing line with Aceretech.

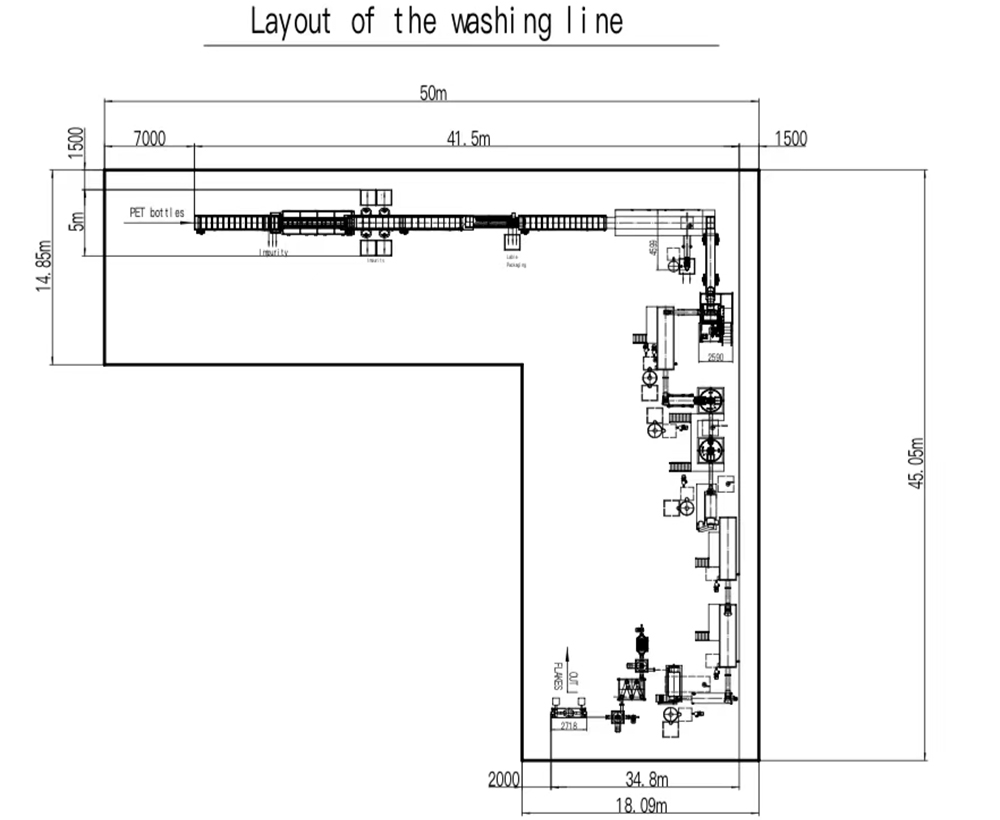

According to the design of the client's warehouse, Aceretech makes the adaptation and creates this layout. And of course we can make everything Flow-chart according to the clients' warehouses.

It is a 1000kg per hour PET bottle washing line, and with optical sensors and control of the incoming bottles, it can reach food grade, which is the most fashionable thing now.

Normally, if with these flakes after washing, they are already considered food grade:

PET Polymer Final: 50-100PPM.

Surface moisture less than 2%, 2000ppm.

PVC (Flakes, label) content: max 50PPM

Glue content max 2000ppm.

Yellow flakes, PET color max 200PPM,

PH value: Neutral (PH+/- 0.5)

HDPE/PP Content: max 20ppm

PET dust (Particle size less than 1mm.): max 3-5%

Metal content: max 30PPM

Wood paper cellulose: max 20PPM

Silicone, rubber, content: max 20ppm

Other contamination: max 10ppm.

Flakes size: 4-16mm.

Bulk density min. 290g/l

And then with the Aceretech pellet machine, we can make rPET grade pellets.

PET is the most used plastic in the world due to its characteristics, in the Water, Food, Salad, etc. industry. And it is the most recyclable. We can help you with the FDA certification processes, since we have already had FDA for PET for our machines.

Aceretech we are developing the entire solution from washing, to pelletizing, and rPET sheet. We contribute a lot to the technology for rPET.

Welcome with your rPET inquiries, and we are here to serve.

PET Recycling is very hot

2024/04/22

in Company News