Customer Success Story: Revolutionizing EPS Recycling in Denmark with ACERETECH

We at ACERETECH are committed to providing our clients around the world with state-of-the-art plastic recycling solutions. One excellent example is our collaboration with a customer in Denmark, who used our EPS foam material recycling pelletizing system to accomplish impressive efficiency and sustainability targets.

Client Challenge: Tackling High-Volume EPS Waste

Our Danish client required the processing of up to 1000 kg/h of EPS foam waste from industrial and packaging applications. The lightweight, bulky nature of EPS posed logistical challenges, driving up disposal costs and environmental impact. They looked for a high-capacity, effective system to convert this waste into resources that could be used again.

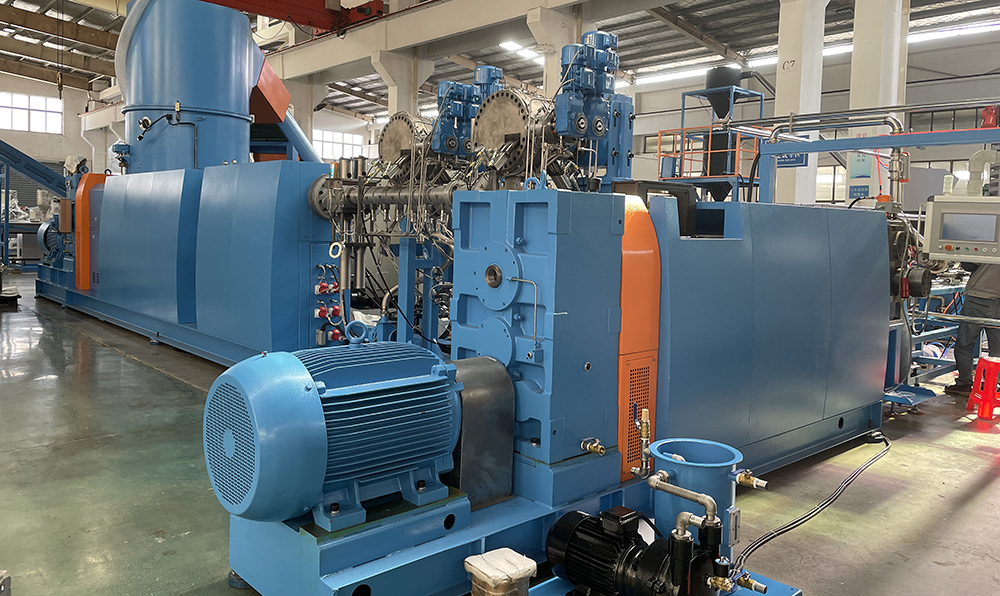

ACERETECH Solution: High-Capacity EPS Recycling Line

We provided a customized EPS recycling pelletizing system with a 1000 kg/h throughput capacity. The system crushes EPS into manageable pieces, compacts it by up to 90%, and turns it into consistent, premium pellets thanks to its sophisticated compacting technology and precision pelletizing unit. This streamlined process met their demanding capacity needs with ease.

Results: Efficiency Meets Sustainability

The results were impressive. The client reduced waste volume significantly, cutting transportation and disposal costs. The high-quality EPS pellets were reused in new products, boosting profitability while supporting Denmark’s sustainability initiatives. The system’s energy-efficient design further lowered their operational footprint.

Why It Worked

Our success in Denmark is a testament to ACERETECH's emphasis on innovation and customization. We transformed a waste problem into a business advantage by precisely matching the system to the client's requirements—high capacity and dependable output—and providing ongoing technical support to ensure seamless operation and long-lasting effects.

Client Testimonial

“ACERETECH’s 1000 kg/h EPS recycling system has transformed our workflow. It’s efficient, sustainable, and delivers top-quality pellets that enhance our production. Working with ACERETECH has been a game-changer for us in Denmark.”

This Danish client’s story showcases how ACERETECH’s technology can handle high-volume EPS recycling, blending environmental responsibility with economic benefits. Ready to turn your EPS waste into opportunity? Contact us today!