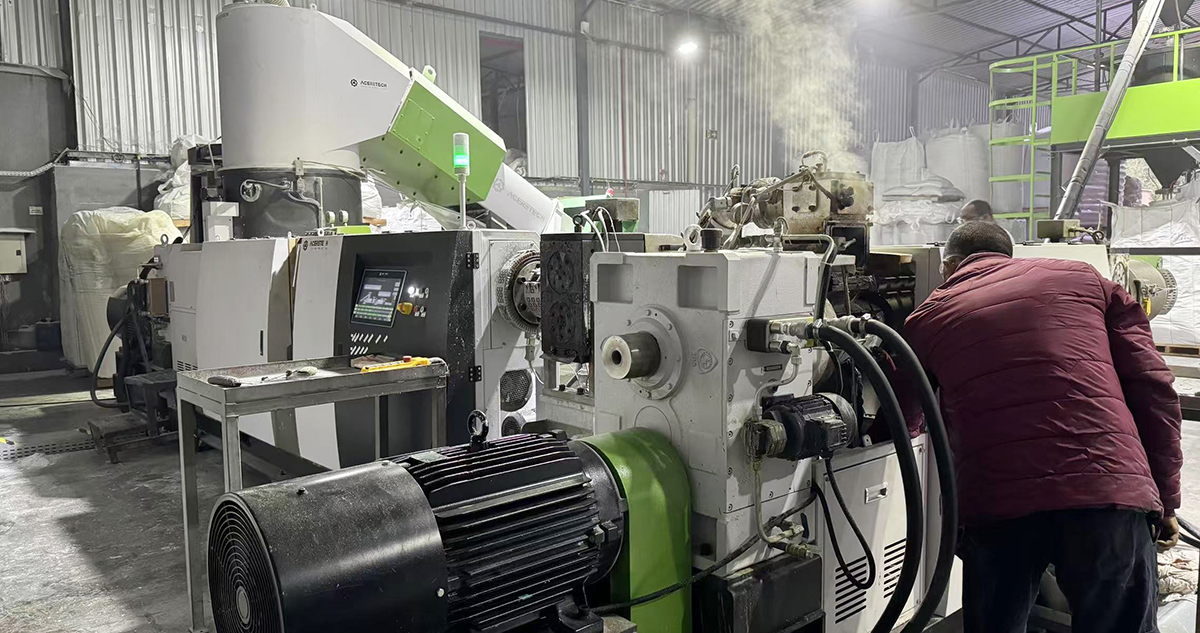

Customer site: Brazil

Raw material: Crushed PP woven bag

Capacity: 300-350kg/h

ACSS double stage compacting pelletizing machine designed for washed PP/PE film, PP woven bags, heavy printed film/bags, EPS foam material etc.

Compactor equipped with auxiliary heater to pre-dry the material

Sliding gate to control the feeding volume to extruder

Double vacuum degassing system, one is 1st stage extruder, another between 1st and 2nd stage for better degassing

Large filtration area piston type screen changer with low frequency screen changing time, double filter to present high performance filtration effect, also machine no-stop working

Water-ring pelletizing system, automatic pelletizing system, lower labor cost.

Our pelletizing system one extruder can handle several kinds of material, we only need change water-ring die head. Now at customer site machine biggest capacity can reach 400kg/h which is more than designed theoretical capacity. And this is the first time customer choose Chinese supplier, customer is much satisfied with our machine.