Since the plastic itself cannot be degraded under natural conditions, the accumulated waste plastics also cause "white pollution". At the same time, waste plastics still contain huge renewable resources, and the existence of "white pollution" is a huge waste of limited earth resources. Therefore, the recycling of waste plastics is not only the key to the sustainable development of the plastics industry in this century but also an important measure to solve environmental pollution. In foreign countries, "white pollution" has attracted widespread attention from citizens to governments, from manufacturers to academia, and has made many progresses. In China, waste plastic recycling technology started late, but it has made rapid progress. Many universities, Chemical research institutes, environmental protection departments, and manufacturers have all joined the research ranks.

Waste plastic

recycling technology means that the recycled plastic products are directly

processed and molded after identification, classification, cleaning, crushing

or dissolution, and melting, or through mechanical blending or chemical

modification, and then processed and molded. Recycled plastics are plastics in

different forms that still have recycling value after their service life ends.

Almost all thermoplastics have recycling value. Recycled plastics will be

produced due to these processes, such as the synthetic resin production

process, the production and processing of plastic products and semi-finished

products, the plastic logistics process and after consumer use. For example,

factory waste plastic, what is produced during synthesis and processing is

called pre-consumer plastic; Some material such as supermarket shopping bags,

food packaging, beverage bottles and other waste plastics,what is produced

after circulation, consumption, and use is called post-consumer plastic.

Plastics produced before consumption are small, with stable quality and high

recycling value. They are properly handled in the production process and can be

completely reused. What we call recycled plastics normally refers to recyclable

plastic products that lose use value after consumption and can be recycled.

After recycling, concentration, classification, and scientific and reasonable

disposal, plastics can obtain renewable value and realize recycling.

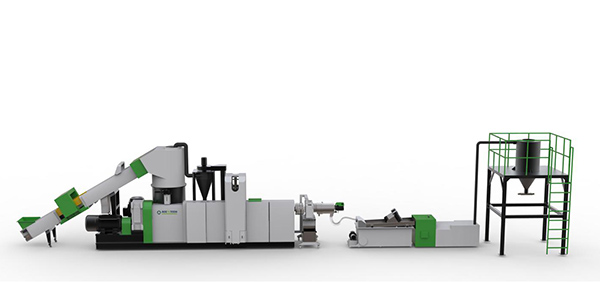

Therefore, Aceretech

has designed a new standard ACS-PRO recycling pelletizing unit for different

materials. The re-optimized design of the ultra-long-diameter ratio and the

design of vacuum after the middle section self cleaning filtering is especially

suitable for high impurity content and heavy ink materials. The variable

frequency speed regulation of the compaction chamber motor combined with the

sliding door device at the feed inlet allows ACS-Pro to not only handle the

recovery of loose materials, but also the recycling and pelletizing of hard

plastics.