Article paragraph

I. Overview

II. Processing method

III. Sludge treatment

IV. Equipment advantages

V. Company introduction

I. Overview

The recycling and reuse of waste plastics is a part of the resource-based environmental protection industry and circular economy, but it cannot be ignored that the waste plastic itself and its recycling and treatment process will have adverse effects on the environment. Therefore, only by improving the recycling process and reducing recycling and reprocessing Only by reducing the secondary pollution can we realize the double harvest of waste plastics recycling environment and economic benefits.

Reuse of waste plastics, while reducing 8 million tons of landfills, and reducing a large amount of CO2 and SO2 emissions from ethylene refining. It also uses 70% less energy than making plastic from crude oil.

The recycling and utilization of waste plastics has become an important and beneficial supplement to the supply of plastic raw materials, which can effectively alleviate the shortage of resources. At present, the recycling of recycled plastics has played a huge role in promoting environmental protection, expanding employment, increasing taxation and the development of regional circular economy, and has effectively promoted energy conservation and emission reduction. Contribute to environmental economic development and environmental protection.

Wastewater is the main source of pollution in the recycling process of waste plastics, mainly produced in waste plastics cleaning, separation and wet crushing processes. The concentration of pollutants in wastewater is closely related to the properties of waste plastics used in its production. If it is a coarse material containing a lot of sundries, it contains a lot of paper, soil particles and other sundries, and it is made of various types of plastics, the amount of waste water generated is relatively large, which can reach 10t/t of waste plastics, and the cleaning and crushing process produces The waste water has high content of organic matter and suspended matter, among which COD can reach 2000mg/m3, while SS can reach 500mg/m3.

II. Processing method

1. Pretreatment

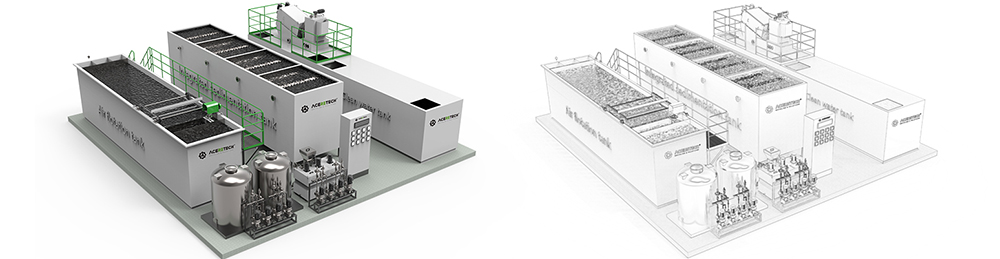

First, the sewage is pumped into the filter through the sewage pump, and the filter equipment filters and separates the large particles of impurities in the sewage, and the remaining sewage flows to the regulating tank.

2. The sewage in the regulating tank is pumped into the sewage clarification and air flotation separation equipment through the submersible sewage pump, and then the wastewater is added with a coagulant to destroy the stable structure of the electric double layer in the wastewater, and then the sewage impurities are flocculated and flocculated by adding a flocculant The sewage enters the double-effect dissolved air flotation dissolved air release area, and the sewage impurities are floated to the upper end of the equipment through the fine air bubbles generated by the releaser, and the sludge is collected into the sludge tank through the slag scraper.

The remaining clean water flows to the clean water reuse tank, and is pumped to the front cleaning process section to clean the materials. The whole treatment process can realize continuous operation and zero discharge.

III. Sludge treatment

The generated sludge is collected and sent to the filter press to be dried and transported outside for treatment.

IV. Equipment advantages

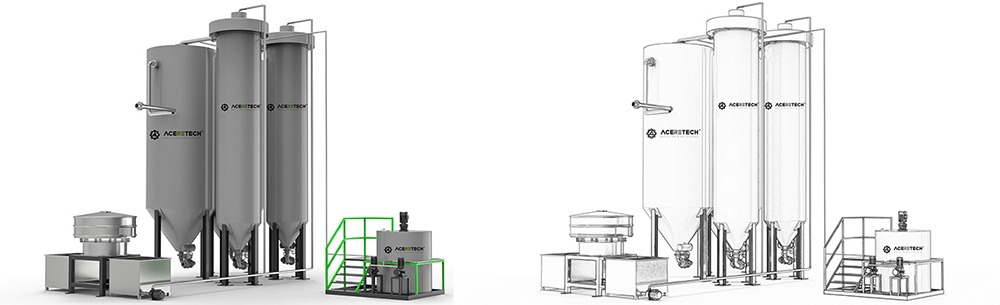

Advanced equipment: After the equipment arrives at the site, it only needs to be connected to water and electricity, and it can be put into use after simple debugging.

Highly intelligent: One-button operation of the human-machine interface, automatic control of the whole process of equipment operation, no need for special personnel to be on duty, and online and remote control.

Good effect: the effluent water quality is stable, can meet discharge standards or be reused, save costs, and quickly recover investment. No noise, no peculiar smell, no residual sludge during operation.

V. Company introduction

ACERETECH is an enterprise specializing in the R&D and manufacturing of waste plastic recycling equipment. It can provide a series of continuous and stable waste plastic crushing, granulation, cleaning and other equipment for plastic recycling in factories and after consumption. In order to better improve the process of plastic recycling, ACERETECH launched the sewage recycling and treatment equipment after cleaning, which can effectively help customers purify sewage, save costs, and achieve water recycling.