Both plastic shredders and plastic crushers are widely used in the field of plastic waste disposal, but they differ significantly in several aspects. This article will focus on introducing the differences between these two types of equipment from five aspects: working principle, application fields, processing capabilities, usage effects, and maintenance.

1. Working principle

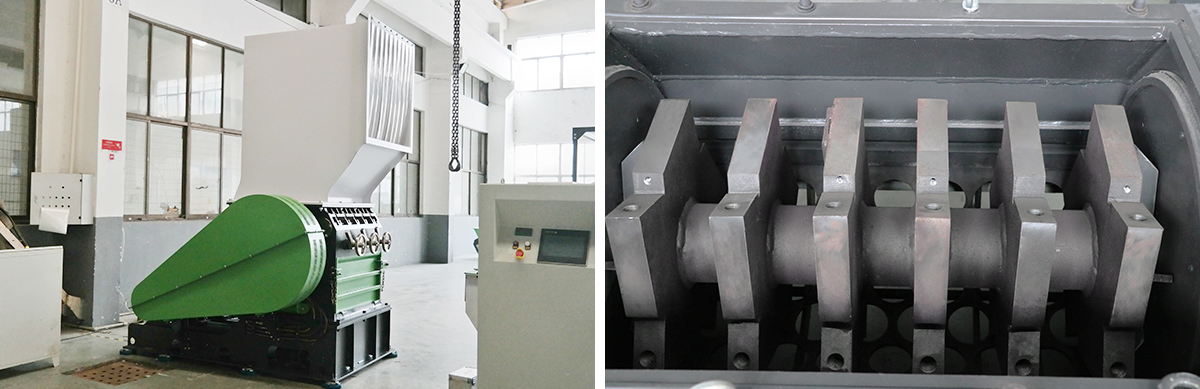

Plastic shredder: It mainly uses the principle of shearing and tearing to tear large or irregular plastic waste into smaller pieces. The shredder is usually equipped with sharp blades or teeth, which crush materials through high-speed rotation or reciprocating motion.

Plastic crusher: It mainly crushes plastics through extrusion, shearing and impact. There is a crushing cavity and crushing cutters inside the crusher. When the plastic enters the crushing cavity, it is sheared and impacted by the cutters, thereby being broken into smaller particles.

2. Application areas

Plastic shredder: It is more commonly used to process large, heavy or difficult-to-break plastic waste, such as used furniture, plastic barrels, large plastic packaging, etc.

Plastic crusher: It is more commonly used to process smaller and thinner plastic waste, such as plastic bottles, plastic films, plastic pipes, etc.

3. Processing power

Plastic shredder: Because it mainly handles large materials, its processing capacity is relatively large and it can handle larger-sized plastic waste.

Plastic crusher: Because it handles smaller materials, its processing capacity is relatively small, but its crushing efficiency is high, and it is suitable for processing a large amount of small plastic waste.

4. Effect of use

Plastic shredder: The size of the shredded materials is relatively large and the degree of fragmentation is low, but it is more conducive to subsequent crushing or reuse.

Plastic crusher: The crushed materials are smaller in size and have a higher degree of crushing, and can be directly used in the production of recycled particles or other reuse areas.

5. Maintenance and maintenance

Plastic shredder: Because it handles larger materials, the blades wear faster, so the blades need to be checked for wear regularly and replaced in time. In addition, the cleaning of the shredder is also very important to avoid clogging of the machine due to material residue.

Plastic Crusher: Although the blades wear out slowly, they do require regular inspection. At the same time, the crusher needs to be cleaned regularly to keep the crushing cavity and cutters clean and prevent material residue and blockage.

To sum up, there are obvious differences between plastic shredders and plastic crushers in terms of working principles, application areas, processing capabilities, usage effects, and maintenance. When selecting for use, appropriate equipment should be selected based on specific needs and characteristics of the materials being processed.

The difference between plastic shredder and plastic crusher

2024/01/02