Whether we’re aware of it or not, we rely on plastic products every day. From makeup and kitchenware to medical tools and storage, this amazing material has completely changed our world — but as our reliance on these products increase, so must our awareness. PP, PET, HDPE, LDPE, and PSE are all commonly used plastics. Today, we’re going to take a close look at the strategies for polypropylene recycling so we can better protect our environment.

The importance of polypropylene recycling

As mentioned briefly, recycling PP is critical when it comes to minimizing waste and protecting our environment. Products made of PP which are dumped in landfills can take around 20-30 years to completely decompose, and unfortunately, most residential recycling receptacles and local recycling centers are not equipped to recycle PP, which requires either companies or individual consumers to seek out companies which handle polypropylene recycling. These key sustainability factors are crucial to bolstering pp’s environmental benefits.

Environmental benefits of recycling PP

Aside from minimizing what’s chucked into the landfills, recycling PP reduces the amount of plastic being produced from scratch, which also reduces the environmental impact of ground pollution, greenhouse and landfill gasses.

Recycling PP also helps conserve natural resources (e.g. timber, water and minerals) and conserves energy. It’s estimated that 8% of all of the oil used in the world (around 400 million tons) is used in plastic manufacturing.

In fact, according to Waste Management, recycling one ton of plastic saves:

5,774 kilowatt-hours of energy

16.3 barrels (685 gallons) of oil

30 cubic yards of landfill space

How to recycle polypropylene plastic?

The recycling process of polypropylene involves several phases, which include:

Collection

Shredding and Crushing

Sorting and Cleaning

Compacting and Pelletizing

Phase 1. Collection

In this first stage, PP is collected from polypropylene collection receptacles and transported to the recycling facility. Collecting the plastic to be recycled depends on how the individual business or individuals public dispose of their plastic waste. When it comes to bulk bags specifically, Aceretech plastic bags pressing machine is a great option for manufacturers who go through a large amount of small bulk density materials.

Phase 2. Shredding and Crushing

We will use shredder and crusher to reduce the size of the plastic materials and make it cleaning easier.

Phase 3. Sorting and Cleaning

Then the polypropylene recycling process continues by separating PP from mixtures with other plastics and contaminants. Aceretech washing line can sort the PP plastic out and removes contaminants during this part of the process. Many bulk bags and containers originally held oil or other impurities, and without cleaning, manufacturers are not able to make new products. We can choose to use hot washing and add chemical additives to remove the oil or impurities. Our technology is Europe design which can greatly support our excellent cleaning performance. What’s more, our solutions can be designed depend on your requirements.

Phase 4. Compacting and Pelletizing

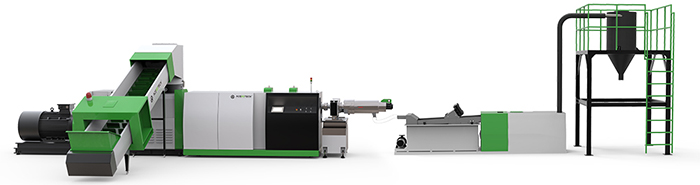

The final phase is compacting and pelletizing. This is the mechanical process of recycling polypropylene. Here, the plastics are conveyed into our combined design compactor, including pre-dry, pre-heating and size reduction, especially suitable for the small bulk density PP plastic films or bags. Because of our uniqure design, you can recycle both soft and rigid materials. Then the materials will be homogenizing and dispersing through our single screw extruder. Our extruder can be customized design based on our requirements. The materials will through double vacuum degassing systems and filtration system to remove the small impurities and improve the quality of the final products. Then the materials will through the mold on the die of the pelletizing system, and be cut uniformly according our automatically control cutting speed. Then the pellets will be dried by the drying system and stored in the final storage silo. Finally, the pellets or granules are ready to be used by manufacturers to make brand new products!

What can polypropylene be recycled into?

There are so many reasons as to why it’s worth putting the effort into recycling PP: it’s better for our environment, our health, and it helps create many new and much-needed products that we rely on every day. Polypropylene can be repurposed to create:

• Dishware

• Gardening materials

• Clothing and industrial fibers

• Containers

• Coffee bags

• Speed bumps

• Storage racks and bins

Recycling PP also creates more jobs and supports domestic manufacturers and local businesses. Polypropylene plastic is an incredibly versatile material that is durable, strong and eco-friendly. However, when not disposed of properly, it can be a pollutant. Fortunately, most products made from polypropylene plastic are recyclable…it just takes a bit of work! Let’s start to recycle the polypropylene plastic and make our earth much better!

The importance of polypropylene recycling

2023/07/11