The customer has already been doing its own HDPE recycling cycle for many years. Recycling is just one sector within its group whose main business is manufacturing and selling plastic products, containers, trays, etc.

The plastic must be sanitized and homogenized. This step of the process will ensure that only HDPE will be processed, since if other plastic polymers are found in the material to be recycled, it can ruin the final product.

Aceretech equipment becomes a plus for this client in their recycling processes, and the quality of the recovered resins is greatly improved, with the 4 pelletizers they have already had since 2018.

♲ What are the environmental benefits of HDPE recycling?

- • The global High Density Polyethylene (HDPE) market is one of the largest; It is estimated that this has an approximate market volume of 30 million tons per year.

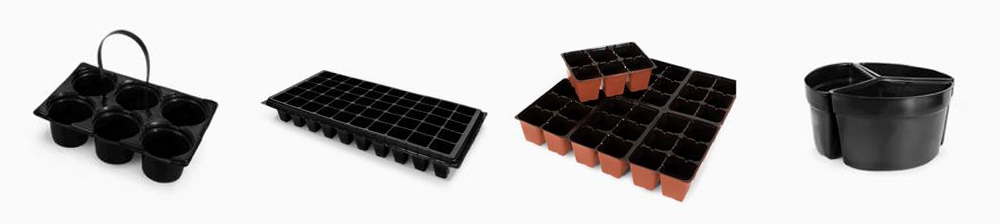

- • The amount of plastic used to make HDPE-based products has decreased by 70% in the last 21 years; This is thanks to the use of biodegradable materials and the recycling of plastic for reuse as raw material for new products such as trays, pots, pallets, etc.

- • High Density Polyethylene (HDPE) is a recyclable material; Due to its characteristics and high malleability, it is a plastic that has properties to be reused and taken into account as a high-quality element for the creation of products.

- • Recycling High Density Polyethylene (HDPE) has many advantages. For example, it is much more economically profitable to produce pallets from recycled HDPE than to make them from “new” plastic.

- • HDPE, like other plastic polymers, is produced with large quantities of fuels; It takes approximately 1.75 kg of oil to make just 1 kg of HDPE. Therefore, recycling this material will always be better for the environment.

This time's project consists of decontaminating post-consumer bottles.

Inside these bottles that are arriving, together with our client's study, we found out that there will be oil, metals such as steel balls, springs, etc. which are designed for daily uses. So with this new washing line, we take a lot into account of the stages to decontaminate these foreign elements, while protecting the blades of the equipment as much as possible in the long term, and reducing unnecessary maintenance.

Below are some of the most important equipment of the washing line:

Crusher and mill equipment

Manual selection and friction washing

Float tub and Spray washer (spray wash)

The spray washer is the last stage in washing, which carries out the washing process with clean water, and then we can obtain the clean flakes, ready for the pelletizing or granulating process.