We all know that in Central America and the Caribbean, they have a big banana industry. And now the industry requires a lot of plastic, such as plastic casings, cluster projectors, etc.

After each harvest, plastic is discarded, creating more and more plastic waste.

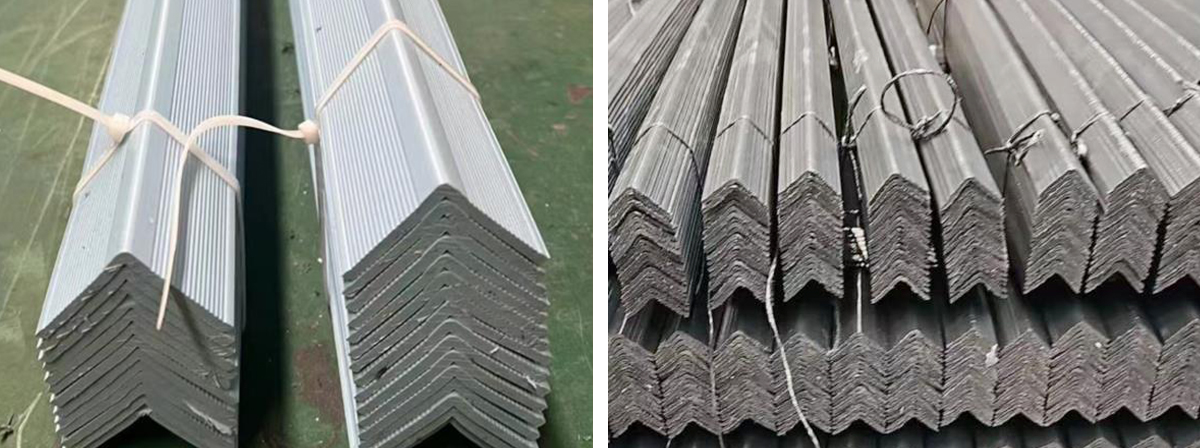

Aceretech developed this project together with our customers in Guatemala to be able to recycle this banana plastic (mainly polyethylene plastic) and enable a second use, in this case, profiles or corners.

In order to obtain the best corner performance, we went through many tests and found the best formula between LDPE, HDPE and CaCO3.

We deliver entire projects from banana film washing and pelletizing to profile extruders to our customers, helping them develop a circular economy and gain more profit for their final products.

As Aceretech says: Easily recycled, valuable plastic. The entire project is controlled by Siemens PLC and equipped with remote modules to support remote data and after-sales service.

It is worth mentioning that in addition to this project, Aceretech has also delivered a similar project to Ecuador in 2022, also for the recycling of banana film. We already have a lot of experience with this plastic material.

The washing line mainly consists of: belt conveyor - crusher - pre-washing - grinding - friction washing - rinsing bucket - press drying and placing until the humidity is less than 5%

Then it is granulated and combined with the Aceretech formula to obtain the final corner product.

We are 100% aligned with our customers and want to do everything we can to support the banana industry.

Aceretech We contribute to the circular economy for a company in Guatemala

2024/03/29