SSP (Continuity) PET Plastic Recycling Machine Line with Solid State Polymerization For IV Increase

SSP (Continuity) Pet Waste Recycled Plastic Pelletizing Machine For IV Increase

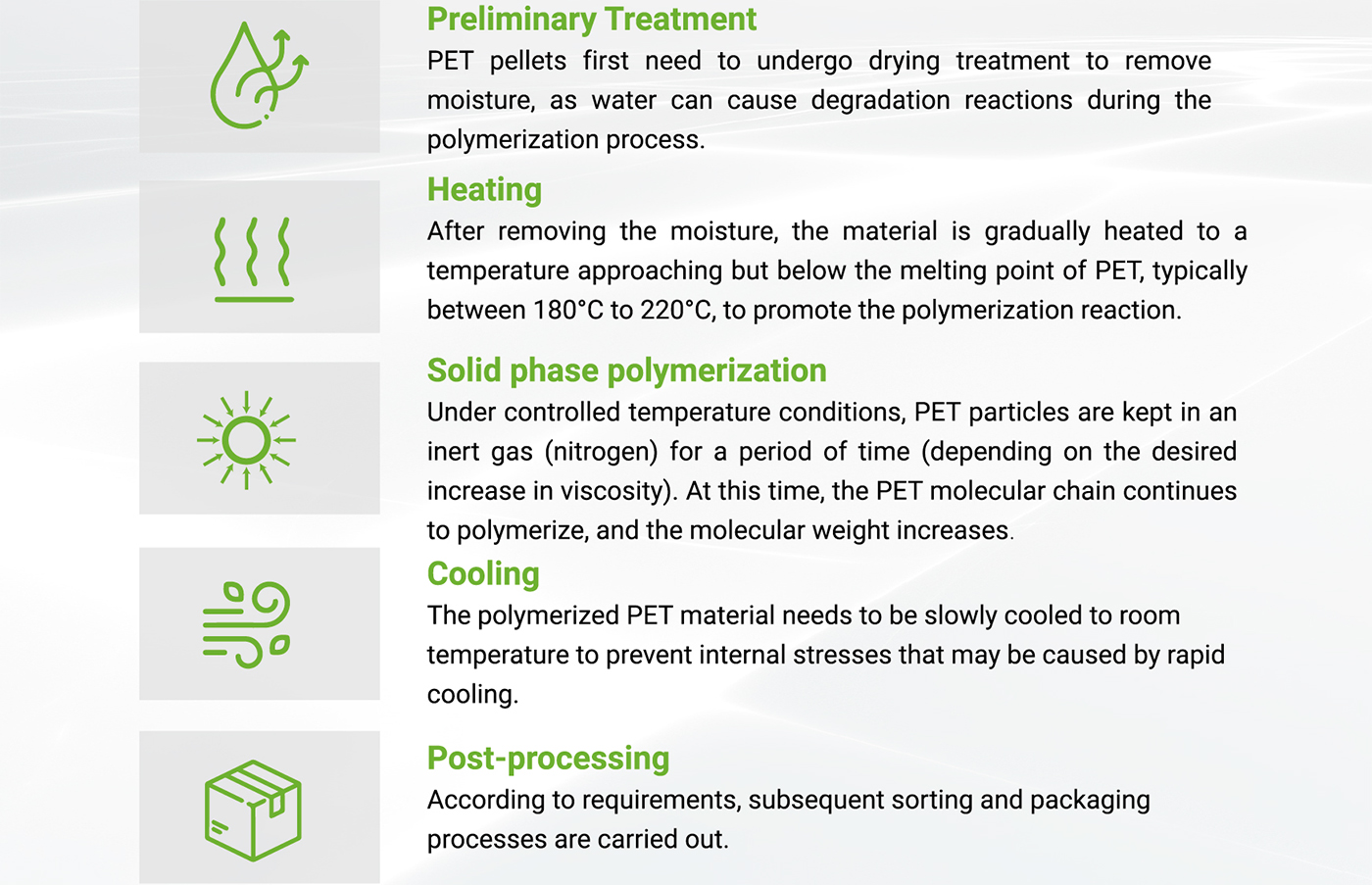

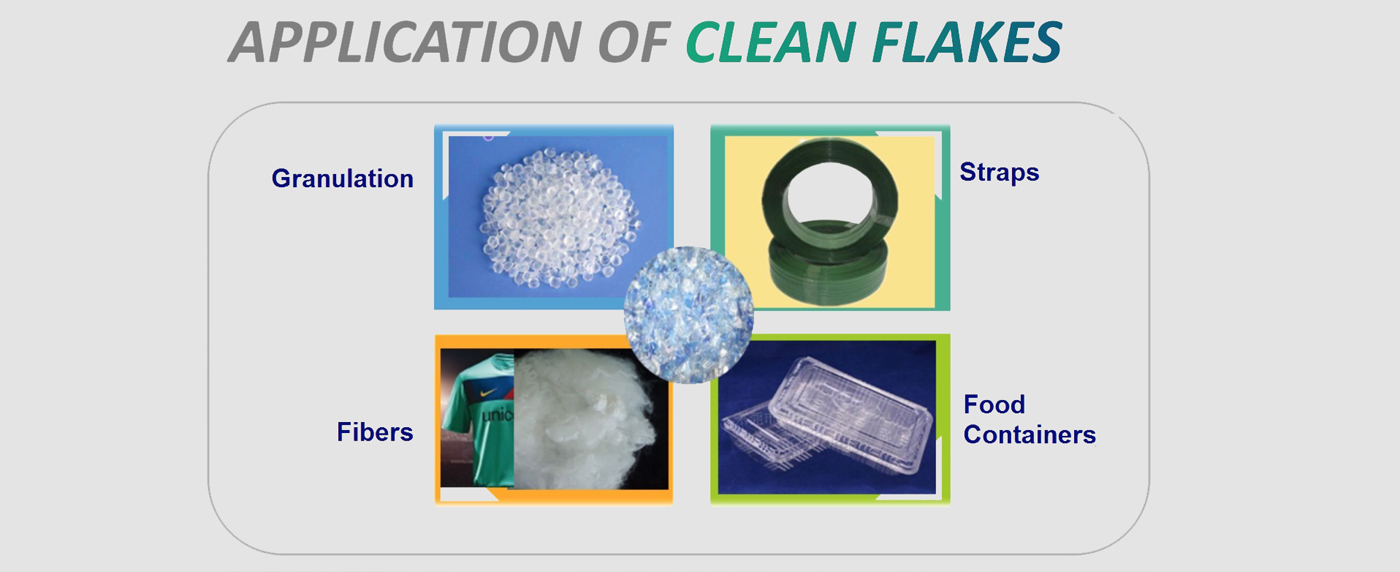

Solid state polymerization (SSP) is a post-processing technique used to increase the molecular weight of polyethylene terephthalate (PET), which in turn enhances the melting point, mechanical properties, and chemical stability of PET. This process is commonly employed in the production of bottle preforms and other PET products. The solid state polymerization process takes place attemperatures below the glass transition temperature and above the melting point of PET, allowing the PET particles to remain in a solid state.The advantage of solid state polymerization (SSP) lies in its ability to increase the molecular weightof PET without compromising the material's properties. This is directly related to the performance of the final product, such as improved mechanical strength and enhanced chemical stability.Further more, the SSP process can also remove low molecular weight substances from the material, such as residual monomers and oligomers, thereby increasing the purity of the product. SSP (Solid State Polymerization) is an indispensable step in the manufacturing of PET bottles, containers, packaging tapes, and other engineering plastic products, especially for applications that require high-performance PET.

Recycling & Material

SSP (Continuity) Pet Waste Recycled Plastic Pelletizing Machine For IV Increase

The latest efficient recycling solution. Thanks to the vacuum technology, the SSP IV increasing technology, and the pelletizing extruder specially made by Aceretech, the IV value of the final PET granules can meet the requirements, and this value can be stably maintained. Even there are uneven IV values and moisture content of the raw materials, the final pellets can be maintained at a reasonable, qualified IV value within a set interval, meanwhile the quality and the output are always stable. It can maintain a stable IV value output for further downstream processing and molding, such as stretch blow molding, up to 100% bottle-to-bottle technology in new bottles.

* Higher viscosity increase efficiency, with a maximum actual viscosity increase of 0.02 per hour.

* Two sizes, 12000L and 24000L, modular design, can be freely combined according to production capacity.

* Digital control, user-friendly interface, easy to operate.

* Compared to traditional polymerization processes, the production assembly is modularized andminiaturized, making post-maintenance and operation simple.

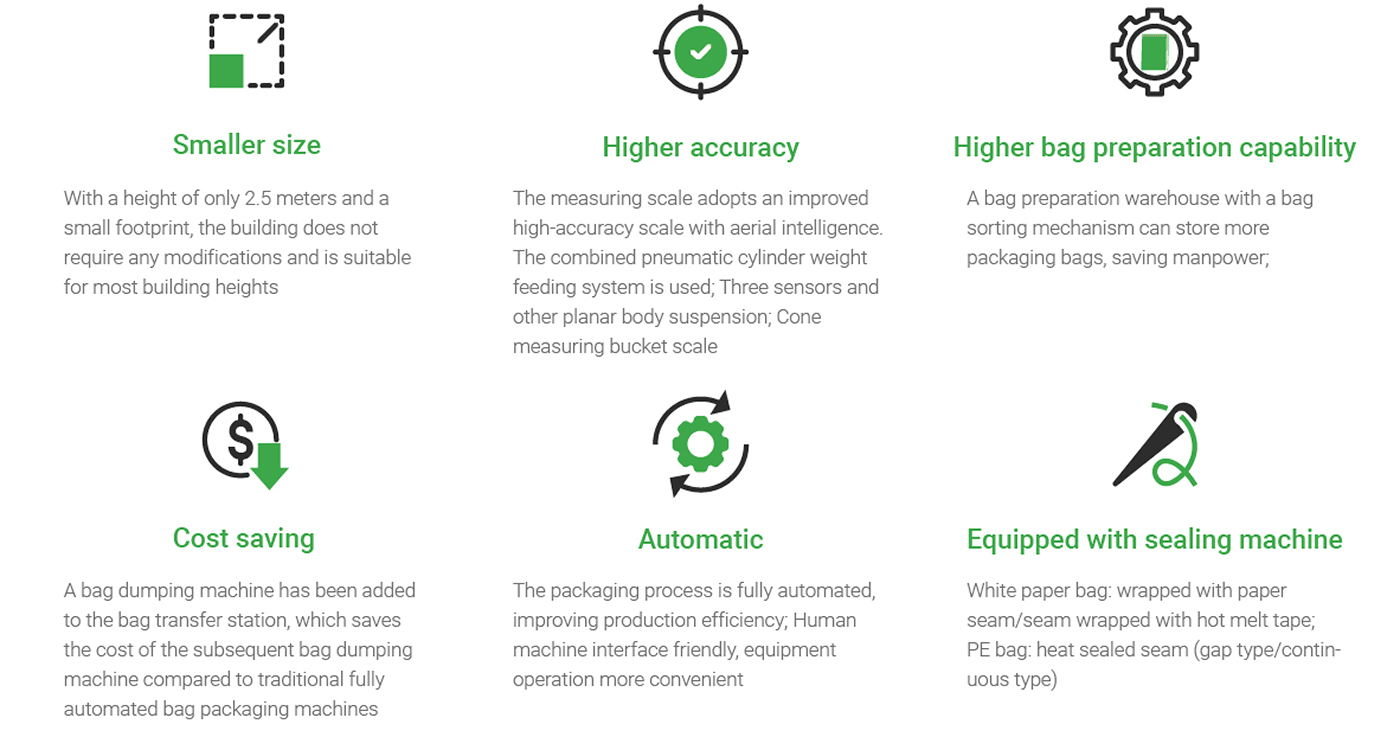

Product Features

Parameters

|

Model

|

Material to be packaged

|

Weighing range

|

Packing speed | Packing accuracy | Power |

|

|

Pellets |

20-25kg/bag

|

200bag/h | ±0.1% | 2kw |

|

ACGS-DA(R)

|

Gas consumption

|

Weight

|

Working condition

|

Air pressure

|

Noise

|

|

|

18 m ³ /h |

1.5-2t

|

0-40℃

|

0.5-0.7MPa

|

≤ 75db |

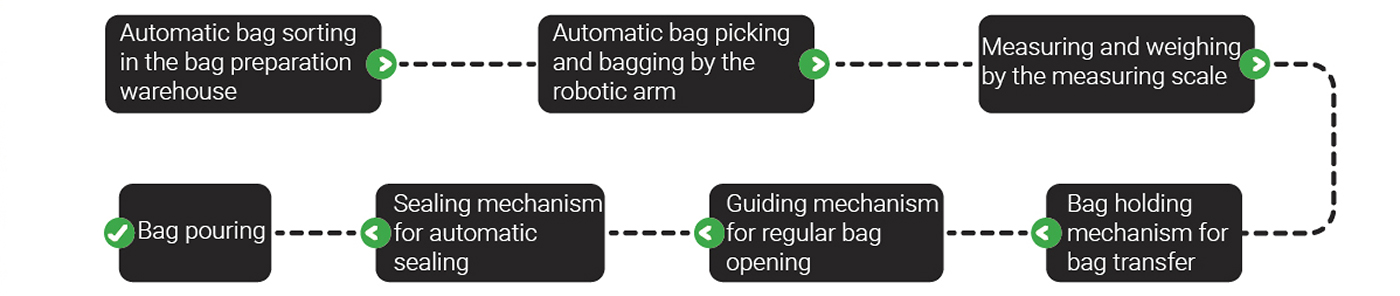

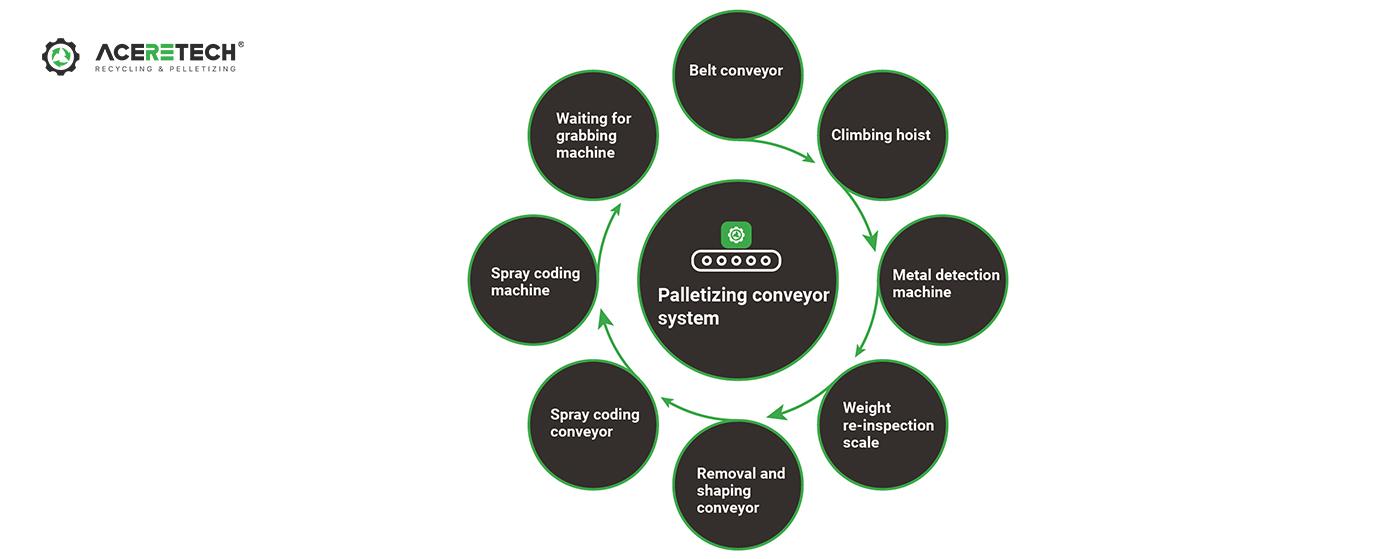

Palletizing Conveyor System

After the sealed package is poured onto the receiving belt conveyor, the climbing conveyor lifts the package to the required height for robot palletizing and grabbing. It then enters the weight recheck scale to recheck the accuracy. Products with unqualified accuracy are removed by the removal and shaping machine, while qualified products are shaken and shaped by the vibration shaping and pressing conveyor. After shaping is completed, the package is transported to the position of the coding

conveyor for coding. After coding is completed, the package is transported to the grabbing conveyor and waiting for the robot to grasp the palletizing.

Palletizing Conveyor System Including

Stacking Robot System

* Adopting ergonomic design, comfortable and lightweight operation ;

* Display in both Chinese and English, with a user-friendly interface ;

* Dual safety switch, fully ensuring the safety of personnel operation ;

* Equipped with USB interface, supporting import/ export of teaching programs ;

Tray Storage System

The pallet storage warehouse transports empty pallets to the palletizing conveyor through the empty pallet conveyor and waits for the robot to palletize them. When there are material packages on the grabbing conveyor, the robot starts palletizing and stacks them onto the pallet of the palletizing conveyor; Complete the palletizing operation according to the prescribed grouping mode, and the full stack of material packages will enter the online winding machine for automatic film wrapping, and then be covered with film on the top by the top covering machine; The wrapped products enter the full stack fork picking conveyor and wait for the forklift to pick them up.