WTS20 Hot Alkali Washer Online Water Recycling Treatment And Reuse System (20T/H)

WTS20 Hot Alkali Washer Online Water Recycling Treatment And Reuse System (20T/H)

Project profile

Pet bottle washing processing will make lot of wastewater, Main pollutants are suspended matter.According to the wastewater amount and pollutants index. Building a set water treatment system is planned.Adopted filtration + sedimentation + air flotation process, After the wastewater is treated, part will be reused, and part will be discharged up to standard.

Design principles

1. According to the sewage quality and treatment requirements, the process route shall be reasonably selected, the treatment technology shall be advanced, and the treated water quality shall meet the discharge standard.

2. On the premise of meeting the treatment requirements, the original facilities shall be used as much as possible to reduce the investment, and the requirements for beauty in the plant shall be considered.

3. Convenient operation and management, simple operation and simple maintenance. The equipment and equipment are of high quality, good performance and stable operation.

Design parameter

1.Waste water source

Plastic recycling plants

2.Designed treatment capacity:12m³/H

3.Efluent quality

Specifications

|

Item |

SS(Suspended Substance)

|

PH

|

| Inflow quality | <1000 | 7-14 |

| Efluent quality | <100 | 6-9 |

Treatment technology

For our hot alkali water filtration system, the main objective is to remove the SS from the water and retain the agent in the water. This system adopts precipitation + filtration process.

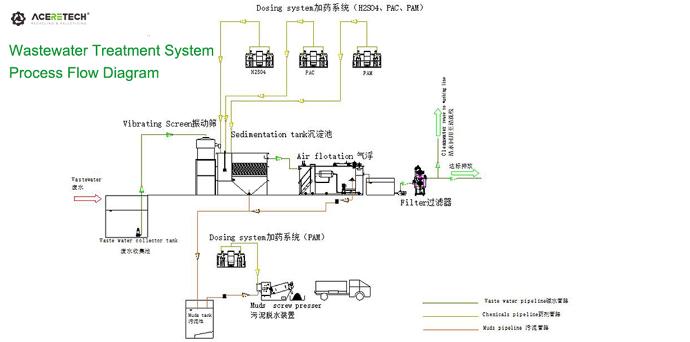

Process flowchart as following:

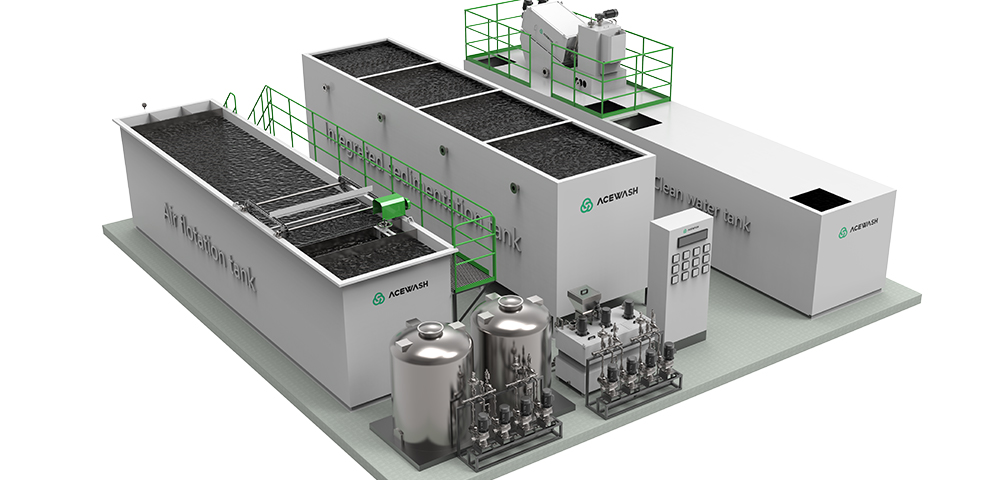

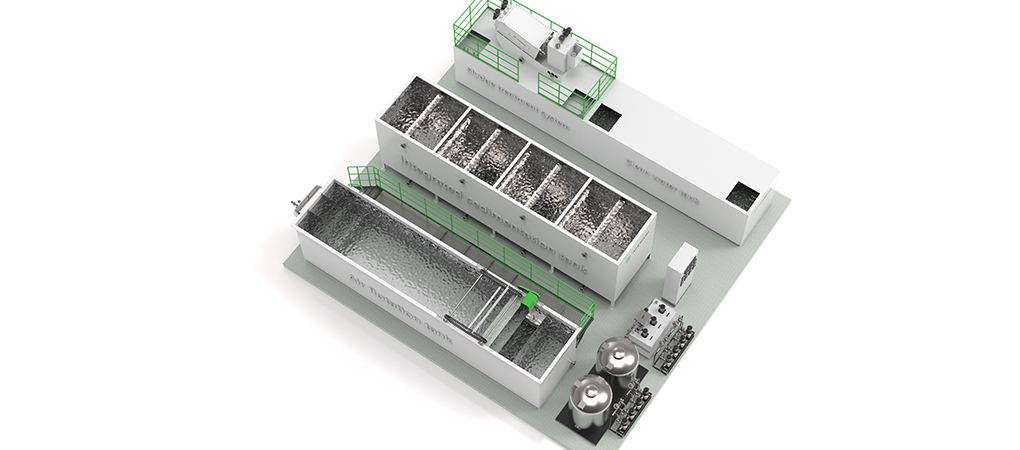

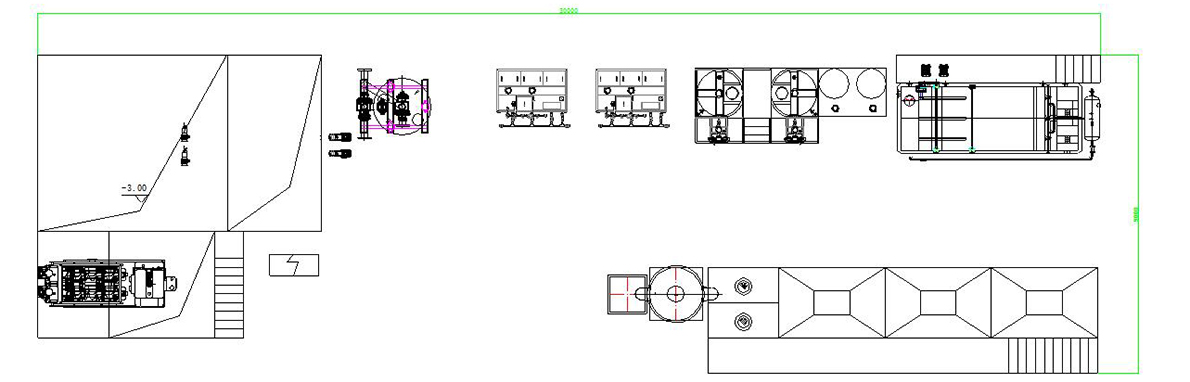

Layout Chart:

Process Description

The wastewater from the washing line is first discharged to the wastewater collection pool for collection and temporary storage;

Step 1: the wastewater conveyor to the vibrating screen for solid-liquid separation by the water pump, the larger particles into the slag collection box, and the wastewater into the sedimentation tank;

Step 2: After the wastewater into the sedimentation tank, According to the online PH meter feedback date, automatically added acid and adjust the PH index to neutral, then added flocculant and coagulants to the flocculation reaction.

Most of the condensed flocs will sink, and the clear water will float up and into the air flotation tank to realize the separation of mud and water, and the mud water will be discharged to the sludge tank regularly;

Step 3:Clear water into the air flotation tank, and when compressed air is mixed with water, micro-bubbles are produced, The residual fine particles and the floating matter will float to the surface of the pool by the air bubbles, then, are discharged through the scraper device; After treatment the clean water into the water pool temporary storage.

Step 4: Clean water will be conveyor to the filter by the High-pressure pump and filtered water goes back to the washing line.

The sludge produced by the sedimentation tank and air flotation into the sludge tank, and dewatered by the sludge dewatering device and then transported out for treatment regularly.

2. Main Process Introduction:

a.Wastewater collection tank(prepared by customer)

It is mainly used to collect the cleaning wastewater discharged from the cleaning line, and also serves as the sump of the sewage lift pump, which has the functions of buffering the flow change, regulating the water volume, and homogenizing the water quality.

Design stay time:≮2h

Integrated waste water collection pool*1set,Effective volume:40m³

Material:Concrete

Form:Underground

b.Lift pump

It is used to lift the sewage to the sedimentation tank for treatment. The design adopts non-blocking submersible sewage pump, which is easy to install and maintain, and has a long service life. The automatic start and stop can be realized through the level gauge set in the regulating tank, reducing manual operation.

Integrated waste water lifting pump*2set(One for use, the other for backup)

Power:5.5kw

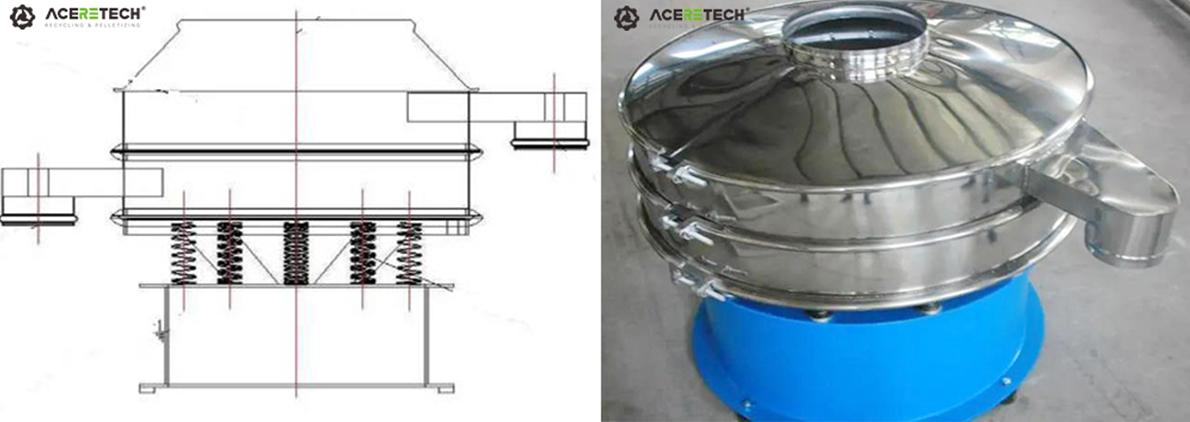

c.Vibrating screen

The circular vibrating screen is set at the forefront of the water treatment system, mainly to separate the larger particles in the discharged wastewater, which is beneficial to the subsequent sedimentation treatment and reduces the blockage and wear of subsequent equipment.

Model:YZS1500*1set

Main Materail:SUS304

304 collection box*1

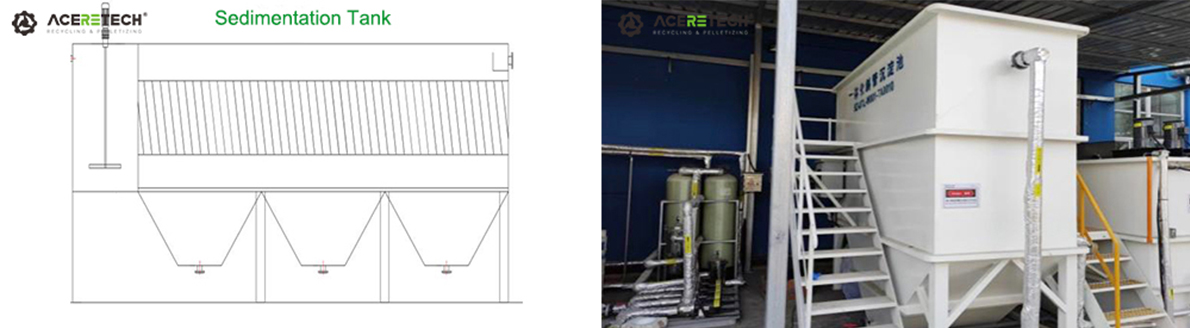

d.Integrated sedimentation tank

The integrated sedimentation tank adopts inclined tube sedimentation tank, which is set at the front end of the treatment system. By adding acid, the PH of wastewater is adjusted to neutral, providing the best conditions for subsequent sedimentation reaction. In this process, the PH set in the reaction tank is interlocked with the acid dosing metering pump to realize the automatic adjustment of PH.

At the same time, by adding flocculants and coagulants, SS in the wastewater can be coagulated and settled, and mud and water can be separated by gravity, so as to clarify the water quality.

Processing capacity:20m³/h 1set

External dimensions:L11000*W2000*H3500

Material:Carbon steel + anti-corrosion

Mud discharge:The mud discharge valve is an electric valve, which automatically discharges mud regularly

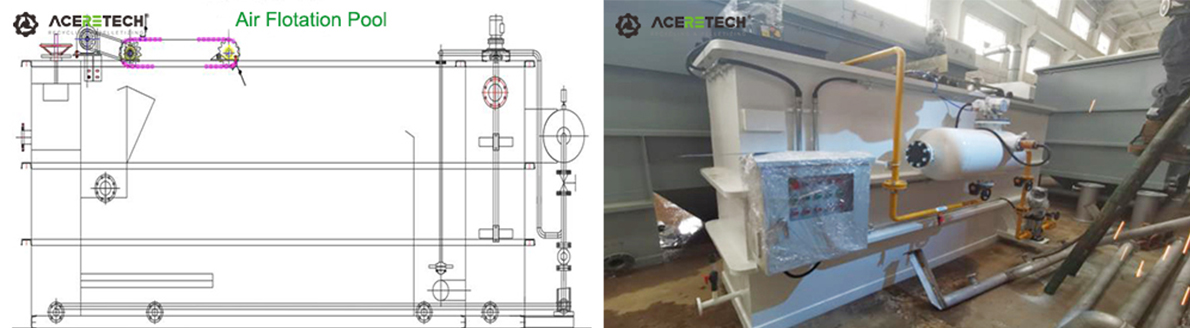

The wastewater after sedimentation treatment will still contain a small amount of floating substances, which need to enter the air flotation tank for further treatment. Air floatation is the dissolved water produced by the dissolved gas system, which is released into the water through rapid decompression to produce a large number of tiny bubbles. Several bubbles adhere to the suspended solids or oil surface in the water, forming suspended solids with an overall density of less than 1. The solid and liquid are separated by buoyancy to make the water completely clear.

Processing capacity:20m³/h 1set

Material:Carbon steel + anti-corrosion

External dimensions:L5000*B1500*H2100

Scum pump:Pneumatic Diaphragm Pump*2set S1FM

f. Clean water tank

It is mainly used to collect the treated recycled water and also serve as the reservoir for the clean water pump.

Design stay time:2h

Effective volume:40m³

Material:carbon steel anticorrosion

Dimensions: L4000*W2000*H1500 2set

g.Clean water pump

It is used to reuse the treated recycled water to the cleaning line. The design adopts vertical centrifugal pump, which is easy to install and maintain, and has a long service life. High level alarm and low level pump stop can be realized through the level gauge set in the regulating tank.

Qty.:2set(One for use, the other for backup)

Power:5.5kw

h.Filter

The treated wastewater is deeply filtered and adopts quartz sand as the filter material, the water flows through the internal water distributor and water collector, and high-speed filtration is performed in the tank, which can effectively remove particulate matter and reduce turbidity.

Qty.:1set

Model:DMF3224-1A

Material:carbon steel anticorrosion

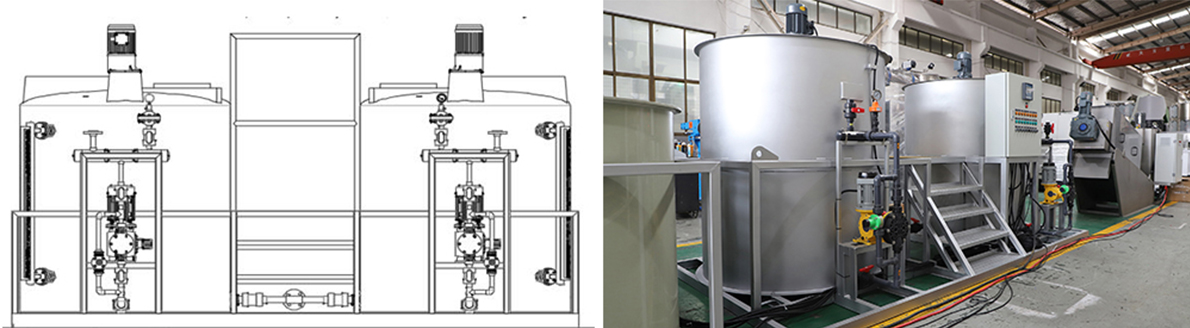

i.Dosing System

The dosing device is composed of metering pump, reagent barrel, agitator, etc., and is used to realize the quantitative dosing of reagent. Among them, PAC is a flocculant with strong bridging adsorption performance, which can coagulate and adsorb with suspended solids in water, so as to destabilize and settle the suspended solids; Anionic PAM is a coagulant, which can be used in combination with flocculant to improve the sedimentation of flocs and facilitate the clarification of water quality; Cationic PAM is used for sludge dewatering, which is conducive to solid-liquid separation. The automatic acid dosing device is used to adjust the PH of wastewater to be neutral, and the automatic dosing is realized through the online PH device.

Qty.:4set

PAM Automatic dosing device:2set Three box type automatic, 304 1000L

PAC Automatic dosing device:1set Double bucket double pump PE 2000L

Automatic acid dosing device:1set Single bucket double pump PE 500L

j.Sludge treatment system

The sludge treatment system consists of sludge thickener, diaphragm pump and filter press

The sludge thickening tank is used to store the sludge produced by the physical and chemical reaction of the sedimentation tank and the air flotation tank. The sludge is transported to the filter press through the sludge pump for dehydration, and the dewatered sludge is transported outward for treatment;

sludge pool*1set:Underground-type concrete structure,volume10m³(Customer provide)

sludge pump:Pneumatic Diaphragm Pump*2set S1FM

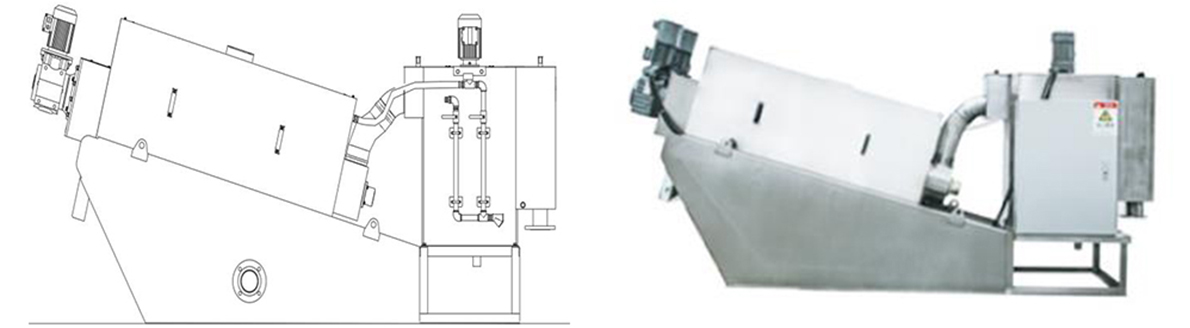

Stamped screw machine:model 301、design and processing capacity:20-70kg.DS/h

Material:304

Equipment size:L3340*B970*H182500

Power:0.95kw

Qty.:1set

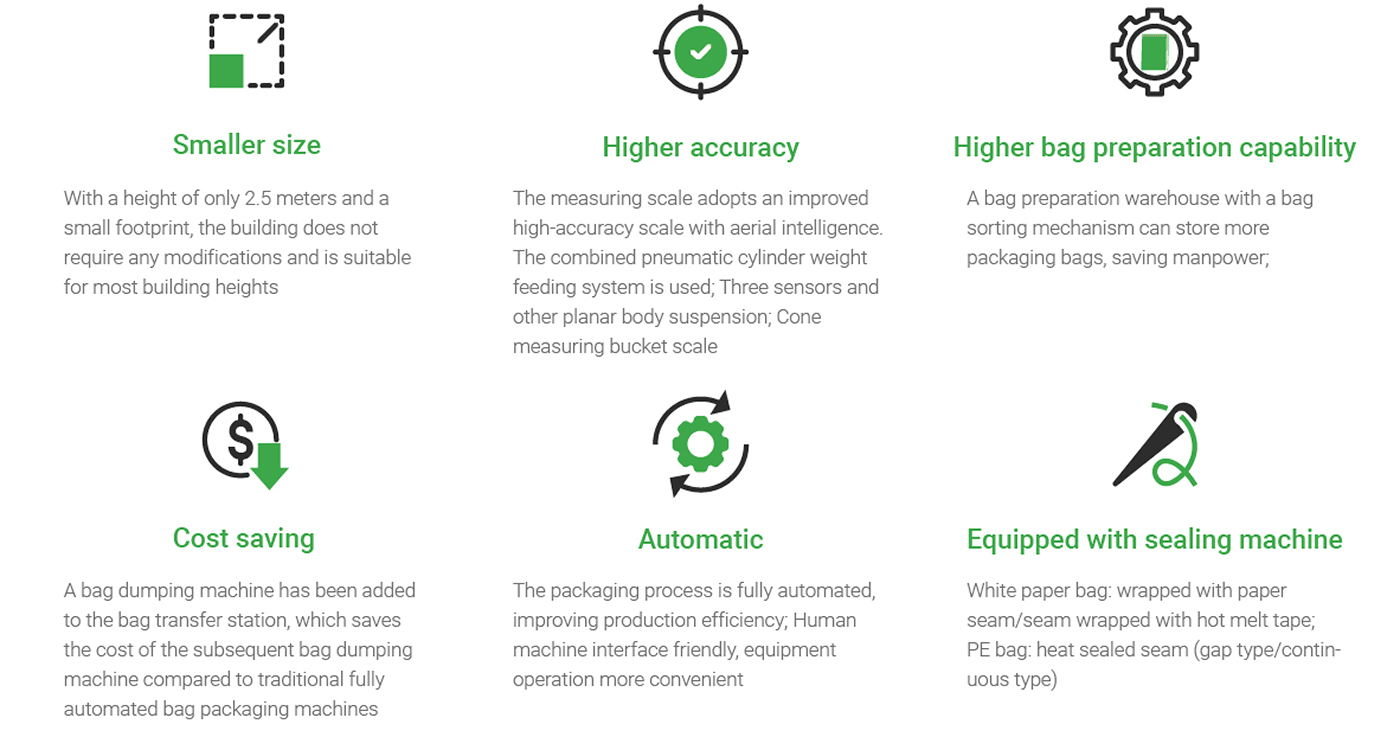

Product Features

Parameters

|

Model

|

Material to be packaged

|

Weighing range

|

Packing speed | Packing accuracy | Power |

|

|

Pellets |

20-25kg/bag

|

200bag/h | ±0.1% | 2kw |

|

ACGS-DA(R)

|

Gas consumption

|

Weight

|

Working condition

|

Air pressure

|

Noise

|

|

|

18 m ³ /h |

1.5-2t

|

0-40℃

|

0.5-0.7MPa

|

≤ 75db |

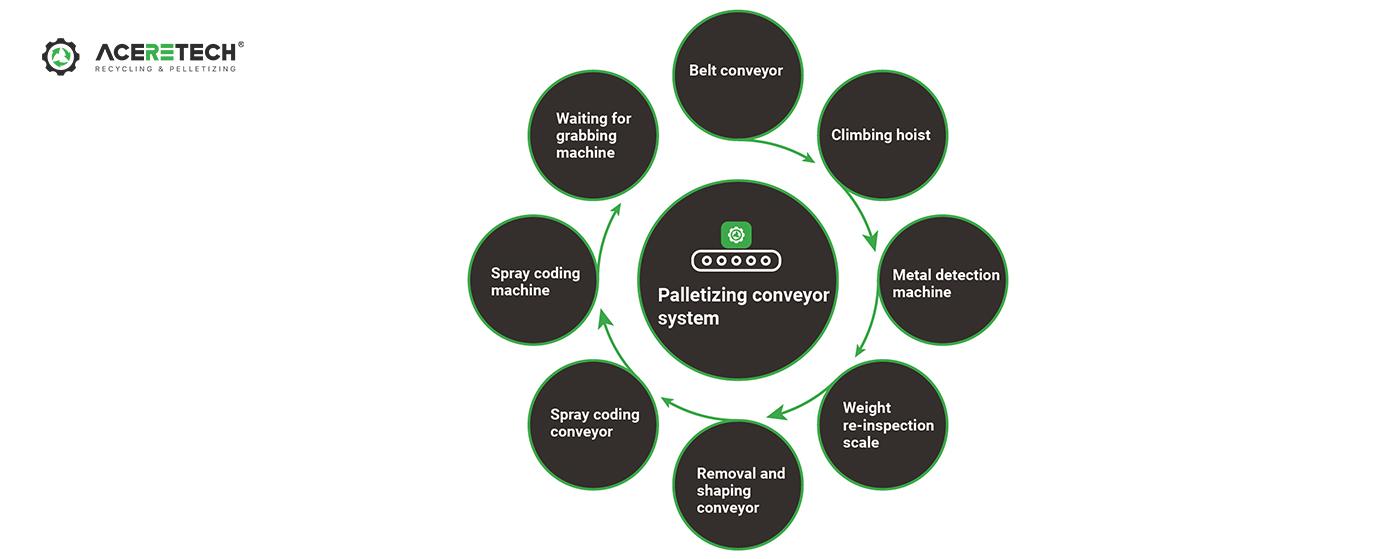

Palletizing Conveyor System

After the sealed package is poured onto the receiving belt conveyor, the climbing conveyor lifts the package to the required height for robot palletizing and grabbing. It then enters the weight recheck scale to recheck the accuracy. Products with unqualified accuracy are removed by the removal and shaping machine, while qualified products are shaken and shaped by the vibration shaping and pressing conveyor. After shaping is completed, the package is transported to the position of the coding

conveyor for coding. After coding is completed, the package is transported to the grabbing conveyor and waiting for the robot to grasp the palletizing.

Palletizing Conveyor System Including

Stacking Robot System

* Adopting ergonomic design, comfortable and lightweight operation ;

* Display in both Chinese and English, with a user-friendly interface ;

* Dual safety switch, fully ensuring the safety of personnel operation ;

* Equipped with USB interface, supporting import/ export of teaching programs ;

Tray Storage System

The pallet storage warehouse transports empty pallets to the palletizing conveyor through the empty pallet conveyor and waits for the robot to palletize them. When there are material packages on the grabbing conveyor, the robot starts palletizing and stacks them onto the pallet of the palletizing conveyor; Complete the palletizing operation according to the prescribed grouping mode, and the full stack of material packages will enter the online winding machine for automatic film wrapping, and then be covered with film on the top by the top covering machine; The wrapped products enter the full stack fork picking conveyor and wait for the forklift to pick them up.