Полиамид (PA) является очень важной частью синтетической волоконной промышленности. Волокна PA6 прочные, высокопрочные и высокоэластичные. Благодаря своим превосходным характеристикам, их применение очень широко, а ценность бизнеса при переработке очень высока.

Недавно мы получили запрос от шведского клиента. Сырьем являются неквалифицированные отходы волокна PA6 (в рулонах или россыпью), полученные в процессе производства на заводе по производству волокна.

Клиент планирует переработать эти отходы волокна, а затем подвергнуть их модификации. Конечное применение — литьевое поле автомобиля. Переработанные гранулы имеют вязкость менее 0,06 дл/г.

Как перерабатывать такие отходы шелка и как поддерживать вязкость после переработки, ACERETECH предлагает индивидуальные решения.

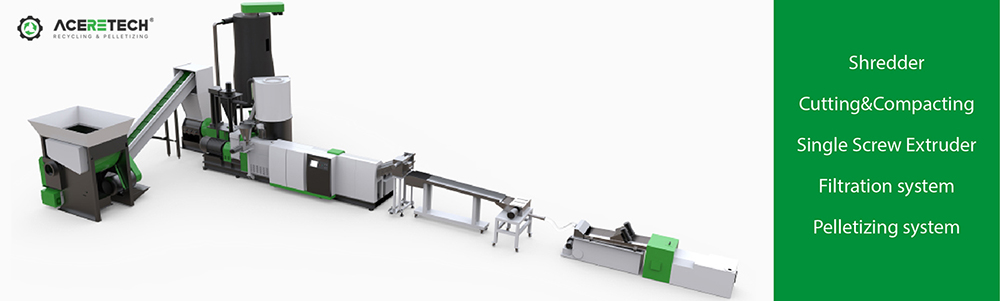

Процесс переработки, включающий две части:

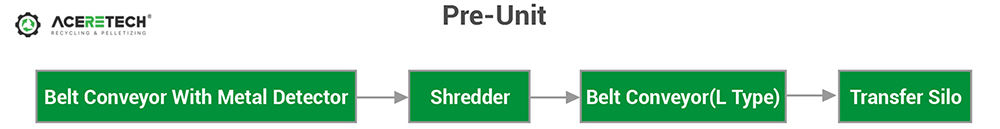

A. Блок предварительной обработки размера:

Из-за гигроскопических характеристик нейлона существует тенденция к реакциям гидролиза во время процесса плавления, поскольку в волокне больше влаги. Уменьшение размера выгодно для быстрого процесса сушки и удаления влаги во время процесса уплотнения, тем самым увеличивая эффективность подачи и производительность. Мы используем измельчитель для контроля размера отработанного волокна: для получения подходящего размера волокна после измельчения.

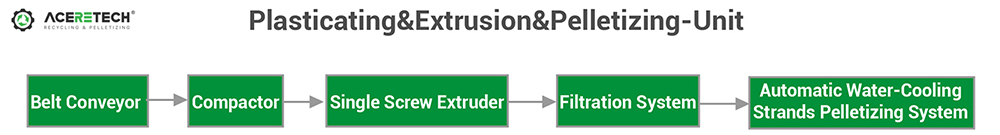

B. Блок расплавления, пластикации и гранулирования экструзией:

Новая система резки, уплотнения и экструзии может обеспечить предварительную сушку и мягкую пластификацию сырья.

Трехступенчатая вакуумная система Рутса может эффективно удалять влагу и мелкие молекулы из расплава и контролировать диапазон снижения lV.

Решения по переработке отходов волокна PA6

2023/10/02

входит в Новости отрасли