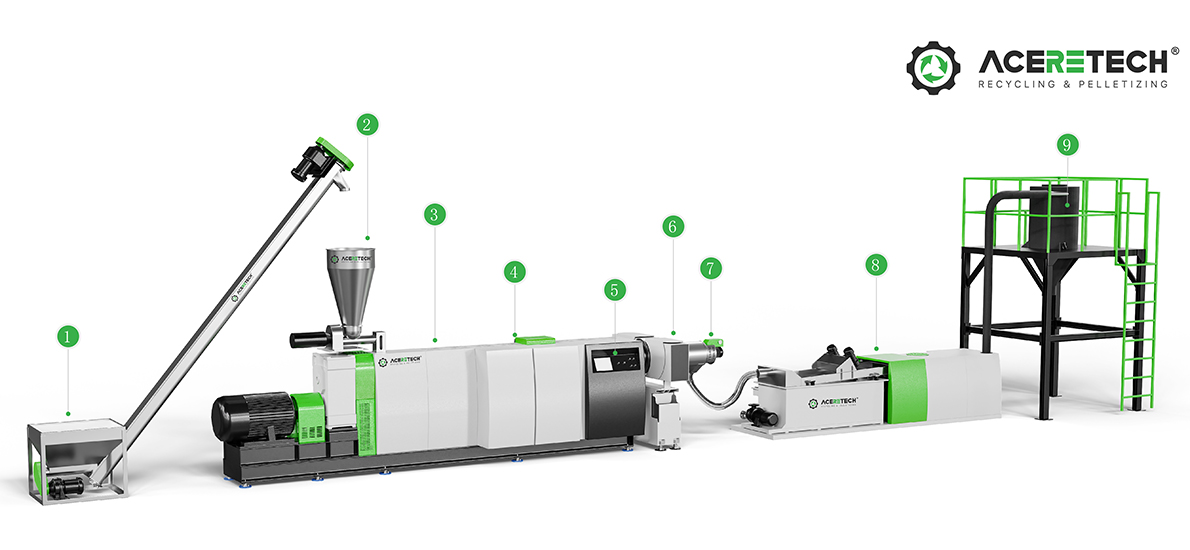

Material Transport

Screw Loader

Lumps or thick flakes after crushed, conveyed into the single screw extruder by screw loader, then, compress, plasticize in the extruder and removed volatiles and moisture by vacuum system, after filtering through the filtration system, to pelletize into granules. Depending on the different screw diameters of single screw, the typical capacity can cover from 100kg/h to 1000kg/h,Loading motor power: 2.2 kw. Conveying pipe made with stainless steel material, pipe inner thickness is 2mm, pipe diameter is 102mm.

Main Feeder

Main Feeder (Volumetric)

It will feed the materials into the extruder. There is a stirring screw to avoid material’s blockage at the bottom of the feeder. Feeding hopper with level indicator. If you want to compound the materials, side feeders are optional.

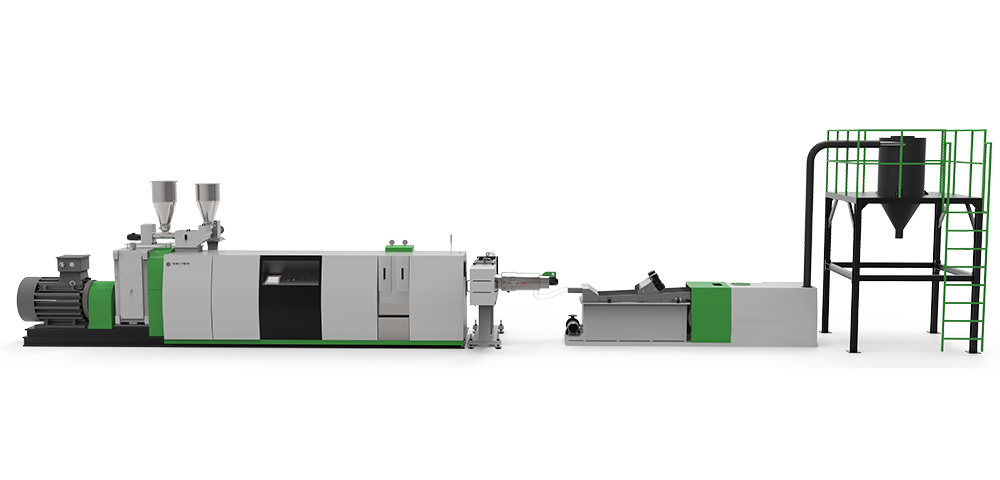

Single Screw Extruder

Barrel

Because of the super L/D ratio, the single stage extruder in the production line can be used as a double- stage extruder. After the middle double-piston type screen filter, another filter can be added at the end. The double filter standard can improve the quality and performance of the final product particles.

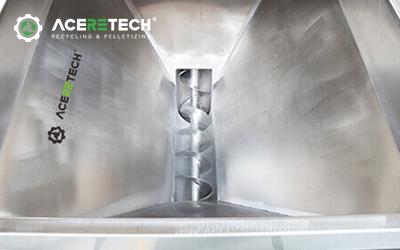

Single Screw Extruder

Our unique design single screw extruder gently plasticizes and homogenizes the materials. Our bi-metal extruder has great anti-corrosion resistant, wear resistant and long life time.

Double Vacuum Degassing Zones

Double Vacuum Degassing Zones

With double vacuum degassing zones, volatile such as micro-molecules and moisture will be removed efficiency to improve the quality of granules, especially suitable for the heavy printed materials.

Intelligent Control

Remote Monitoring And Information Transmission

System program remote monitoring and transmission system,bluetooth both are available for ACS plastic pelletizing line realizing functions of remote monitoring and information transmission.

Intelligent Control

Intelligence Start: One button only Following set logistical sequence and materials processing requirement, interlocked system modules can start by "one button only” Intelligence Stop: One button only Each related modular part in ACS system available to shut down by only one button. Emergency Stop Emergency stop function is available in ACS plastic pelletizing system in case that uncertain risk occurred during machine running.

Filtration System

- A regular single-plate/piston double-station screen changer or non-stop double plate/piston four-station can be installed on head of extruder to present significant filtration performance.

- Long screen lifetime, lower screen change frequency: Long filter lifetime owing to large filter areas.

- Easy to use and none-stop type: easy and quick screen change and do not need to stop the running machine.

- Very low operation cost.

None-stop Piston Type Filter

Plate Type Filter

The Plate type filter is made in a continuous type with two filter plates. There is at least one filter working when the screen is changing.Ring-shaped heater for consistent and stable heating.

Self Clean Filter

This model combines our self-developed self-cleaning filter.The new SCF self-cleaning filtration system makes non-stopping recycling extrusion, especially suitable to highly contaminated materials re-pelletizing. SCF filtration system can handle and remove up to 5% contaminates in the melt flowing, can separate the contaminates as: paper, wood, aluminum, unmelted plastic and rubbers etc.

Pelletizing System

Die Head

This is the most appropriate process for the need for better melt filtration and higher production. In the first stage,two or more single screw extruders can be designed for the two-stage pelletizing production line, and then they can enter the second-stage extruder at the same time.

Water Ring Pelletizing System

- Self-adjusting pelletizing head for the best granulate quality and long uptime thanks to consistently correct blades pressure.

- RPM of rotatory blades is automatic based on melt extruding pressure.

- Easy and fast pelletizer blades changeover, without adjustment work saves time

Strand Pelletizing

The strip-shaped Melted plastic strands passes through the cooling water tank and is quickly cooled and solidified. During the cooling process, the strip is pulled out by the traction device, maintaining a certain speed and stability. Then, the strip enters the pelletizer and is cut into pellets of a certain length by the rotating cutter.

Under-Water Pelletizing System

Highly automatic pelletizing system. It is suitable for materials with high MFI and high production capacity requirements. This system includes pelletizer, valve, conveying pipeline, dewatering vibrating screen, silo.

Vibration Dry

Vibration Dry

- Advanced dewatering vibration sieve combing with horizontal-type centrifugal dewatering present high performance dried pellets and lower energy consumption.

- Assemble sieves: The sieves are installed and fixed by screws instead of welding, so you can change the sieves easily in the future.

Plastic Particles

Final output: plastic particles,the plastic pellets can be re-used for producing high quality plastic products once again.

Packing System

Packing System

- Final qualified granules store here,the drying shaker together with the horizontal centrifuge can get a good drying result, and less energy consumption.

- Capacity online monitoring & Quantitative weighting system.