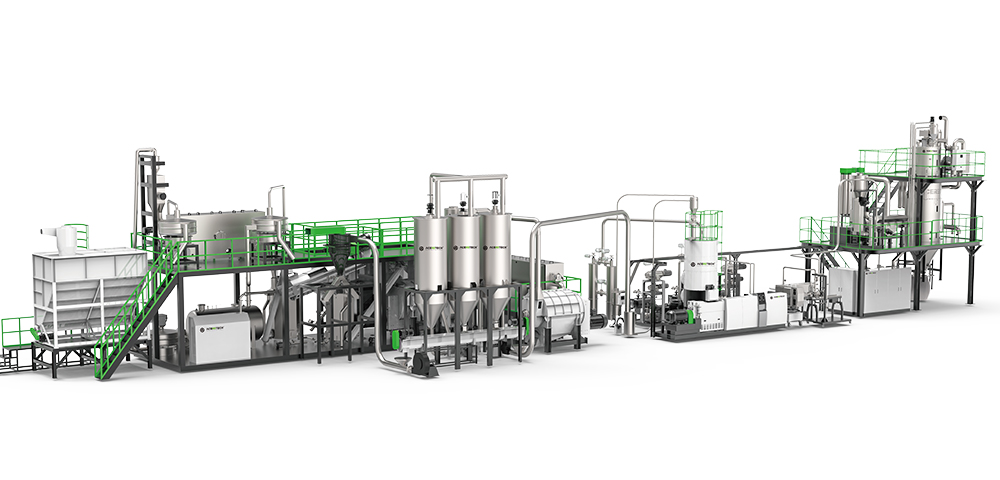

APET Plastic PET Bottles Washing and Pelletizing Recycling line

APET Plastic PET Bottles Washing and Pelletizing Recycling line

As a renewable energy source, plastic can be sustainable.

ACERETECH can achieve regeneration in a closed loop. The solution is made with low energy consumption and high grade standards. Ability to recycle discarded beverage bottles to food grade standards. Our recycling technology makes a big difference.

Recycling & Material

APET Plastic PET Bottles Washing and Pelletizing Recycling line

APET Plastic PET Bottles Washing and Pelletizing Recycling line

ACERETECH can achieve regeneration in a closed loop.

The solution is made with low energy consumption and high grade standards.

Ability to recycle discarded beverage bottles to food grade standards.

Our recycling technology makes a big difference.

ACERETECH able to provide complete solutions

--Washing line

--Pelletizing system

--Viscosity increase system

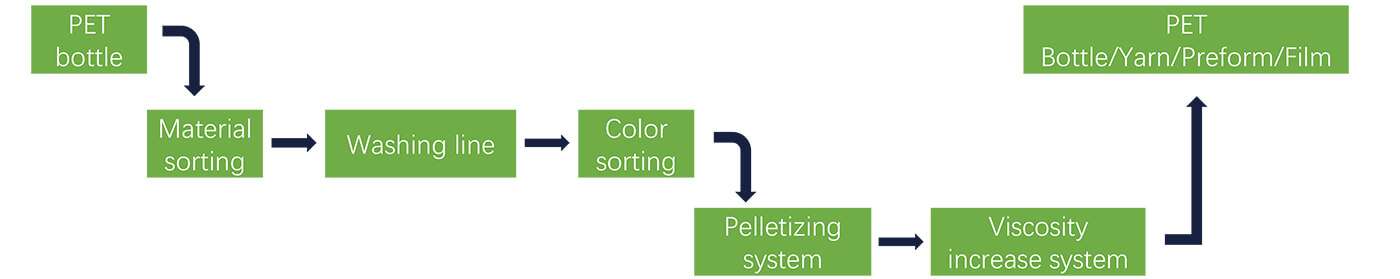

Bottles and Sorting System

Separation of foreign matter and impurities and sorting of the input material.

--Separation of the containers.

--Remove undesired foreign matter and impurities such as wood, sand, glass and metal, as well as coloured plastic materials and foreign polymers.

--Remove labels.

--Crushing into flakes.

The pre-sorting system can be individually adjusted to the quality of the infeed material, the local conditions and the required levels of purity.

Bottles and Sorting System

Belt Pre wash Screw loader

Vibrating feeder

Belt Bottle sorting Belt Manual sorting Crusher

Label remover

PET pellets for high-grade uses require precise recycling solutions.

In the pre-processing at the front end, we select high-quality bottles. Remove sand, wood and other impurities.

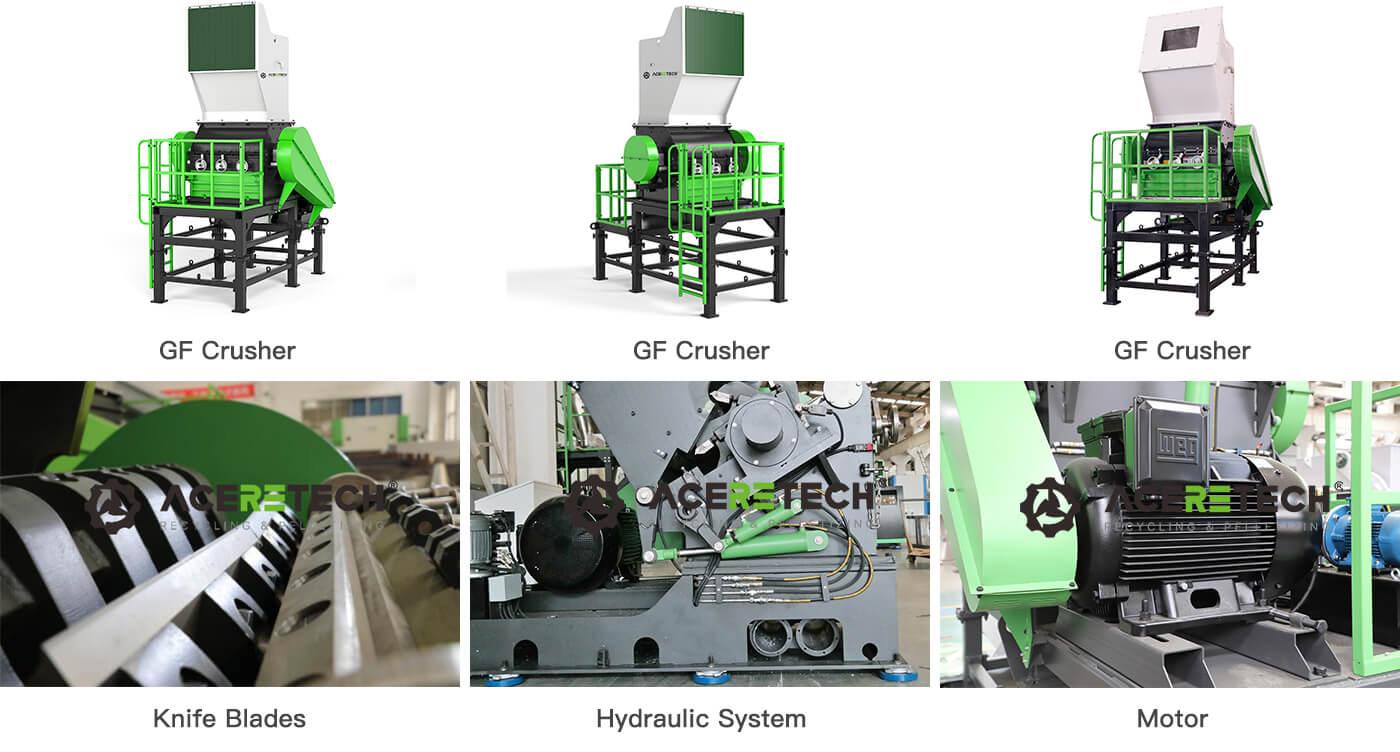

Crusher

* Optimal rotor knife mounting for heavy duty application and high cutting power;

* Better quality cut ( granule shape ) and lower noise level due to exact cutting gap and optimal rotor design;

* With hydraulic system, heavy duty and stronger push power;

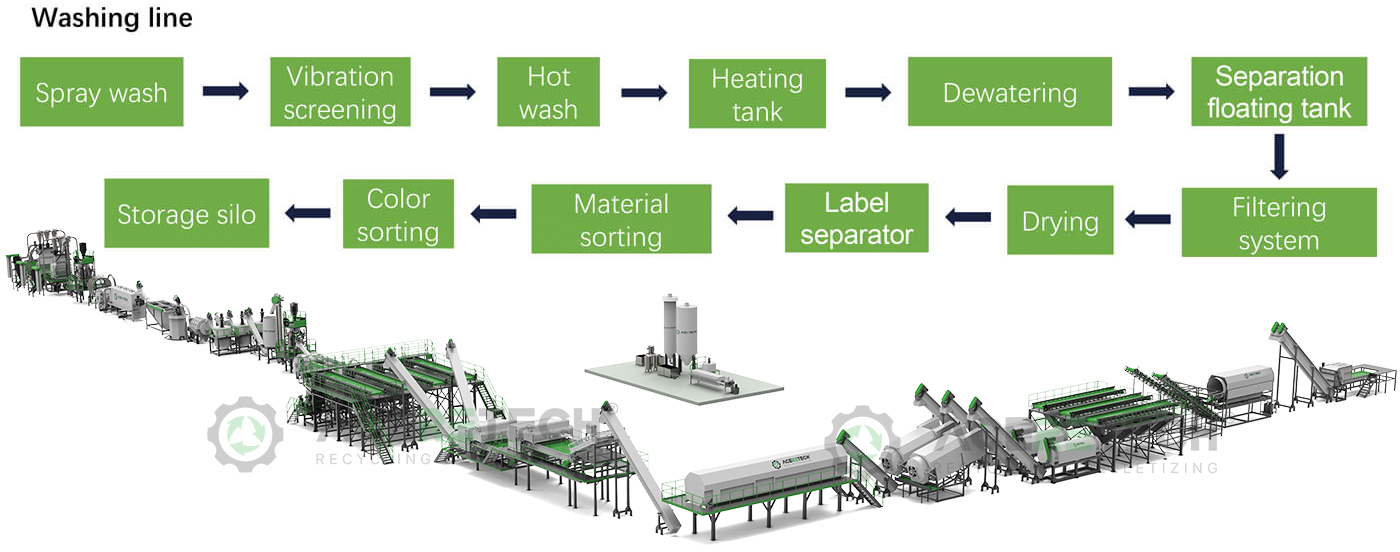

Washing line

Excellent cleaning results with ACERETECH washing technology.

--Pre-washing

--Caustic cleaning with caustic renewal

--Multi-stage post-washer

--Drying

--Automatic waste management system reduces the operator’s work

--Separation of labels and caps using a float-sink separation system and sifter

Pelletizing system

--Vacuum Loader

--Vacuum-state sliding gate feeding device

--Vacuum pump units and dust filtering system

--Reactor with 5 layers combined cutter discs

--Single screw extruder

--Backflush screen changer

--Melt pump

--Melt viscosity online measurement system

--Automatic Under water Pelletizing system

--Packing system

Viscosity increase system -- SSP

Compared with bottle flakes, the advantages of particle viscosity: the particle size is uniform and there is no powder, resulting in a uniform final viscosity.

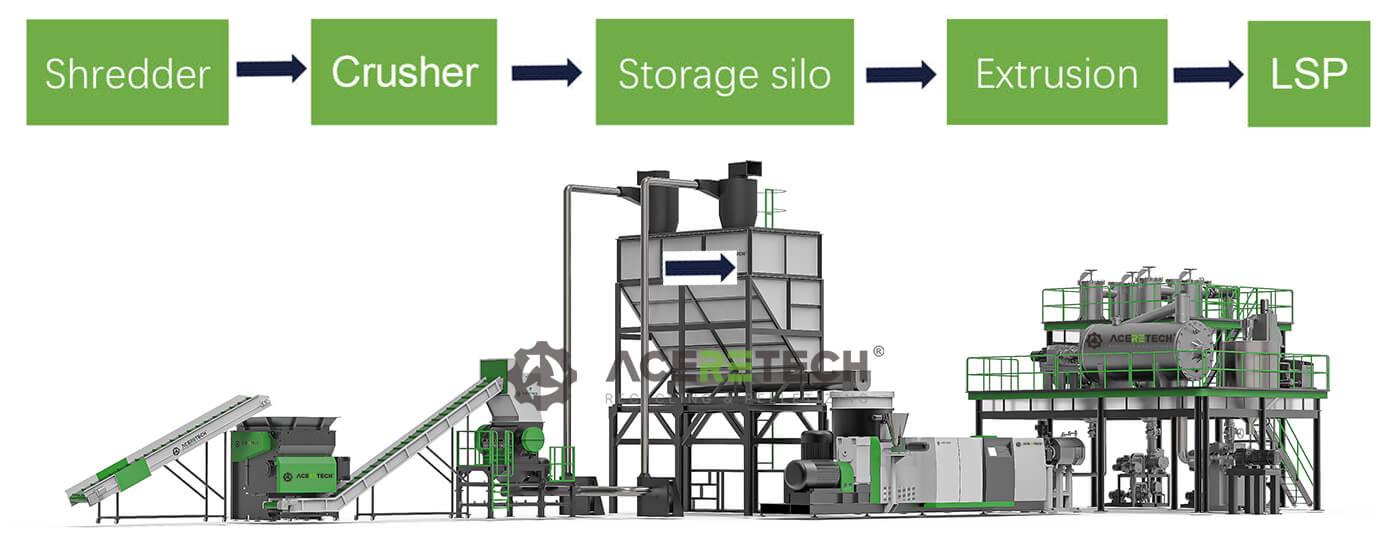

Viscosity increase system -- LSP

For this LSP equipment. the Spray cooling vacuum exhaust device and the multi-screw large area vacuum exhaust extruder are the core equipment. Compared with the normal exhaust device, the spray cooling vacuum exhaust device can increase the empty surface area of PET melt to 1000 times, while the multi-screw large area vacuum exhaust extruder can not only increase the surface area of PET melt, but also can achieve PET homogenization. These two devices combined with a powerful vacuum pump can fully remove the glycol in PET and improve the degree of polymerization of the melt. This process will promote the production of PET new molecule, finally achieve the purpose of increasing the intrinsic viscosity (IV) of PET.

Data terminal consultant systemfor Intelligent

Aceretech can provide washing and pelletizing turn-key solution for allcustomers.

Please contact professional sales team from Aceretech, they will provide you with the customized solutions. All the design drawings and technical specifcations can be provided according to your request.

Installation, Testing and Training

Aceretech can arrange engineer to customers’factory for installtion, testing and training according to your needs. lt will facilitate a better integration for the new factory and new machine.Engineer can offer training lessons at customer's factory during the installation, customer can also send their engineer to Aceretech for training.

The technician from Aceretech will introduce all the parts ofoperation and maintenance equipment for customersengineer.Aceretech will provide detail instruction manuals for all the customers, operation will be more convenient.Before delivery,Acerectch will also provide you layout drawings and other installation requirements,it will help your operators are fully prepared for production,and improve operational effciencies.Please contact sales from Aceretech arrange on-site work.

Spare Parts

Aceretech has spare parts in stock and our highly effcient service staff wil ensure that any required parts are shipped without delay.Spare parts can betransported by air by sea or by courier.dependina on the emeraencycondition.We encourage our customers to hold their own key spare parts. such as pelletizing blades and rubber sealings to ensure best machine conditions and production performance incase spare parts delayed.

Service Support

Your Aceretech sales representative will provide you professional consult. ongoing service and spare parts.