Plastic Recycling Washing Line Accessories

Plastic Recycling Washing Line Accessories

Label Remover

* Mechanically stripping offer lables from bottles instead of by water to save water.

* Label removing efficiency to 90-95%

* Add the protective net to the feed port to guarantee safe.

* Teeth type blades:Made by tungsten steel with copper welded using life will be twice.

Product Parameters

| Model |

Capacity(KG/H) |

Dimension(MM) | Power(KW) |

| LR500 |

500 |

4260(L)x2490(W)x3475(H) | 14 |

|

LR1000

| 1000 | 5475(L)x3122(W)x3680(H) | 20.5 |

|

LR2000

| 2000 | 6354(L)x3247(W)x3940(H) | 37.5 |

|

LR3000

| 3000 | 6123(L)x1600(W)x2865(H) | 55 |

Sink Float Tank

* Paddle speed control by inverter.

* Big angle design for tank.

* Special deisgn for drain screw and slag belt to lift sink impurities.

* Safety hood is equipped to ensure safety standard.

Product Parameters

| Model | Qty of Roller(Pcs) | Tank Width(MM) | Dimension(MM) | Power(KW) |

| SFW1200 | 4 | 1200 | 7200(L)x1580(W)x3680(H) | 6.05 |

| SFW1500 | 8 | 1500 | 8700(L)x1870(W)x3680(H) | 13.4 |

| SFW1800 | 8 | 1800 | 8700(L)x2200(W)x3680(H) | 15 |

Friction Washer

* Speed control device.

* Special design for blade of main shaft.

* Anti-wear steel for blade of main shaft.

* Self-cleaning device for mesh.

* Laser processes for mesh holes.

Product Parameters

| Model | Capacity(KG/H) | Dia of Rotor(MM) | Shaft Speed(RPM) | Power(KW) |

| FW-410 | 500-600 | 410 | 720 | 11/15 |

| FW-450 | 600-800 | 450 |

720

| 18.5/22 |

| FW-560 | 1000-1200 | 560 |

720

| 30 |

| FW-630 | 1500-2000 | 630 |

720

| 37 |

Centrifugal Dewatering Machine

* Heavy duty shaft, exchangeable blades with wear-resistant layers.

* Airpipe cleaning device.

* Special design for blade degree to meet different material.

* Three layers sealing prevents water from bearing.

Product Parameters

| Model | Capacity(KG/H) | Dia of Rotor(MM) | Width of Rotor(MM) | Power(KW) |

| HCD-400 | 300-500 | 400 | 1000 | 11/15 |

| HCD-540 | 1000-1500 | 540 | 1000 | 22/30 |

| HCD-660 | 2000-3000 | 660 | 1400 | 37/45 |

| HCD-900 | 800-1000/soft material | 910 | 1600 | 90 |

| HCD-1200 | 1000-1200/soft material | 1200 | 1600 | 110 |

Pre-Washer

* Low water consumption,95% recycled-release

* Simple water treatment.

* Active material washing processes.

* Self-cleaning device for tank wall.

Product Parameters

| Model | Capacity(KG/H) | Dia of Rotor (MM) | Shaft Speed (RPM) | Power(KW) |

| SW-1000 | 1000 | 580 | 760 | 45 |

| SW-2000 | 2000 | 750 | 760 | 65 |

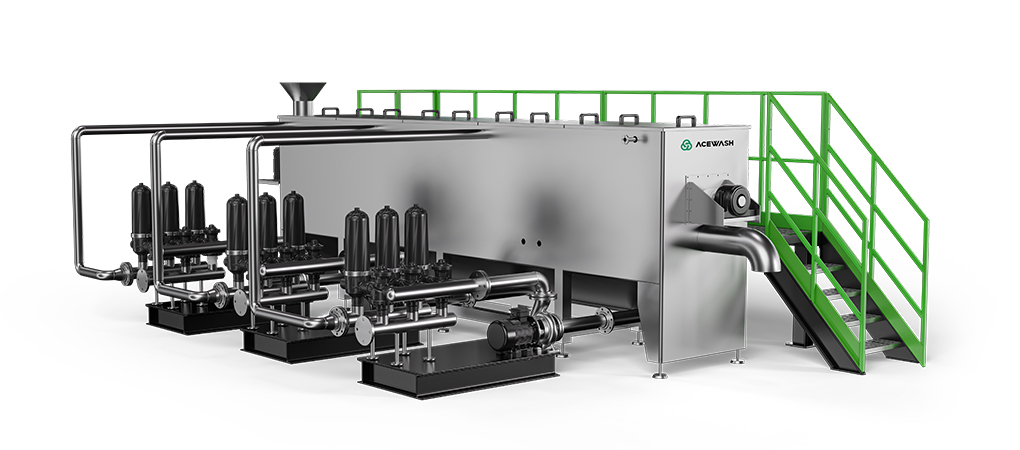

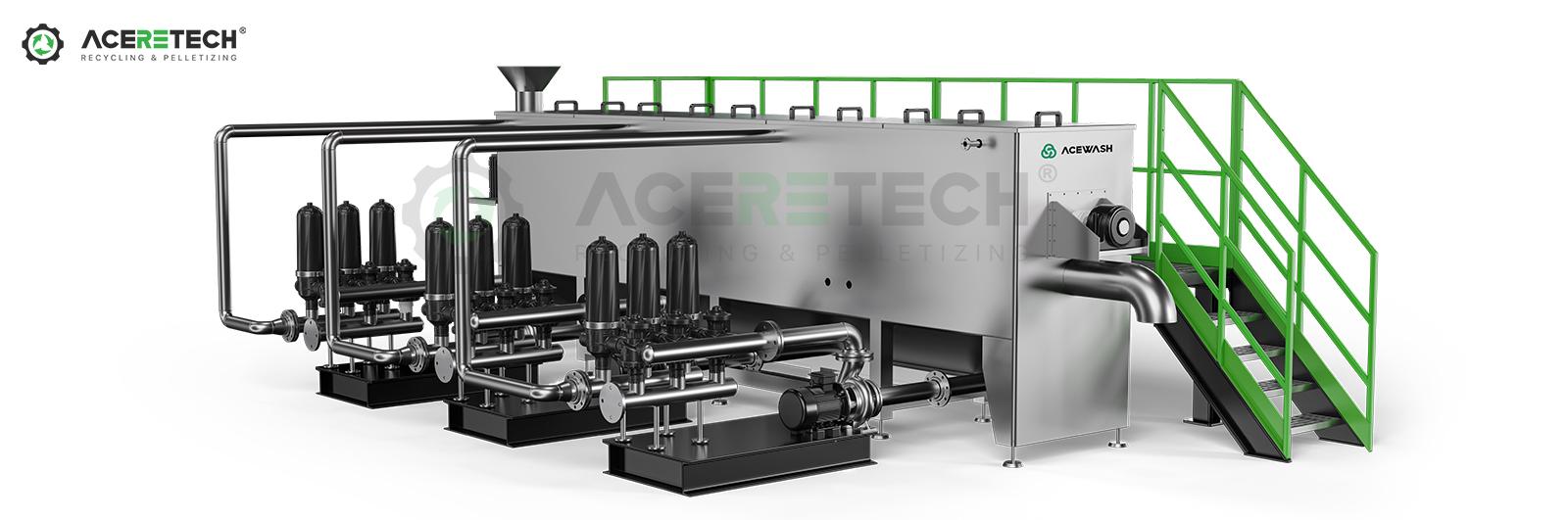

Spray Washer(Cold Water & Hot Water)

* Equipped with water recycling system.

* More effective for hot water spray than cold water.

* The speed of screw is adjustable by inverter.

* Enforced spray could make impurities removing better.

Product Parameters

| Model | Installation Power(Kw) | Circulation Dose(M*/H) | Circulating Pump Power(KW) |

| SW800 | 7.5 | 20 | 4 |

| Rotor Diameter | Effective Working Length(MM) | Overall Dimension(MM) | Processing Capacity(KG/H) |

| Φ800 | 5500 | 7627(L)x4489(W)x2280(H) | 1000/2000/3000/5000 |

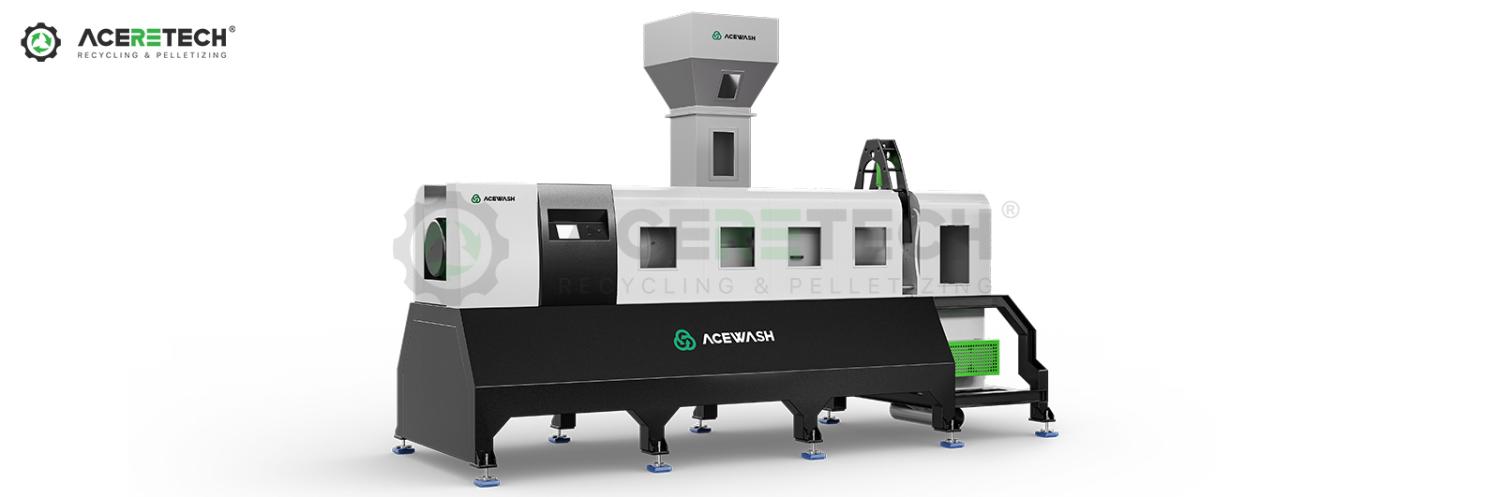

Screw Compactor

* Final product moisture will be 5-10%.

* New design for double-shaft disintegrator,low powerhigh capacity,

easy operation.

* Heavy duty gearbox and bearing parts to provide high torque import

Product Parameters

| Model | Capacity(KG/H) | Dia of Rotor(MM) | Motor power(KW) | Final Product Moisture |

| JG390 | 500-800 | 390 | 22 | 8% film |

| JG490 | 1000-1500 | 490 | 45 | 8% film |

Squeezer Machine

* Final product moisture will be 5-10%

* Heavy duty gearbox and bearing parts to provide high torque import.

* lt has the characteristics of high efficiency and energy saving.

* The equipment could replace the dehydrator and dryer in the whole cleaning production line.

Product Parameters

| Model | Capacity(KG/H) | Dia of Rotor(MM) | Final Product Moisture | Power(KW) |

| NG-320 | 550(PP)-750(PE) | 320 | 2-7%,semi-plasticization | 148.6 |

| NG-350 | 800-1000 | 350 | 2-7%,semi-plasticization | 176.6 |

Six-Channel Label Separator

* Add the bracket and hooks for convenient collection.

* Six channels separation ensures label separation rate >99.5%, dust <1%

* Unique "Z" structure design with dust filter.

* Material outlet is equipped with magnetic rack (as an option) to remove tiny magnetic metal.

* Screen can be equipped to subdivide flake size into 0-1.5mm, 3mm and 3-12mm.

Product Parameters

| Model | Capacity(KG/H) | Removal Lable Rate | Dimension(MM) | Power(kW) |

| LS1000 | 500-1000 | 15-20% | 1656(L)x1155(W)x5030(H) | 6.6/8.6 |

| LS2000 | 1000-2000 | 15-20% | 1656(L)x1155(W)x5030(H) | 8.6/14 |

| LS3000 | 3000-4000 | 15-20% | 1656(L)x1155(W)x5030(H) | 32.6 |

Trommel

* Function: remove stone, dust, loosen caps and small metal.

* Basis material: Galvanized carbon steel.

* Frame: Carbon steel.

Product Parameters

| Model | Dia of Barrel(MM) | Length(MM) | Motor Power(Kw) | Hole Dia(MM) | Basic Material of Beft |

| RMS1000 | 1000 | 4500 | 3 | 50 | PVC |

| RMS1500 | 1500 | 5000 | 5.5 | 50 | PVC |

| RMS1500 | 1500 | 6000 | 5.5 | 50 | PVC |

| RMS1800 | 1800 | 8000 | 7.5 | 50 | PVC |