R-PET Food Grade Pelletizing Line

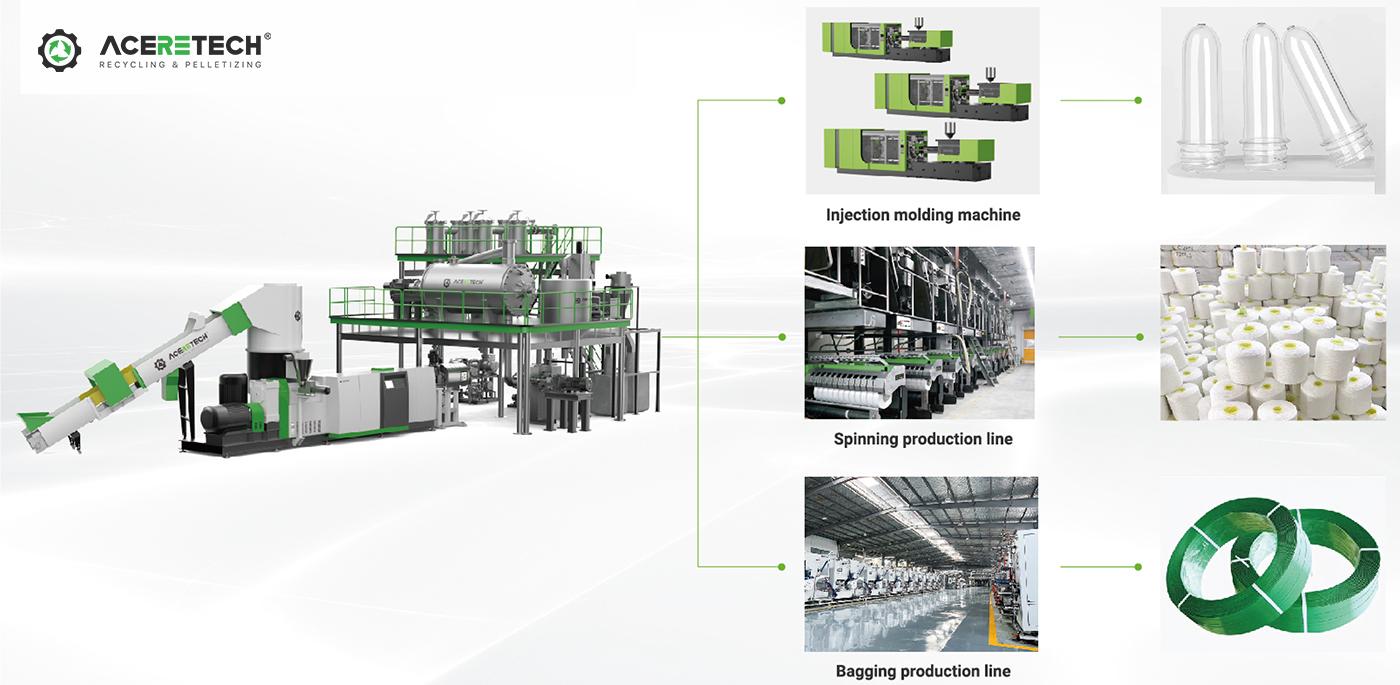

The safPET recycling system can be integrated with PET product production lines, such as bottle preform injection molding machines, spinning lines, and packaging tape production lines, to achieve one step online recycling and production of products.This reduces the material handling process, lowers the energy consumption of the entire production line, and thereby improves production efficiency. maximizing the circular regeneration of PET bottles.

Recycling & Material

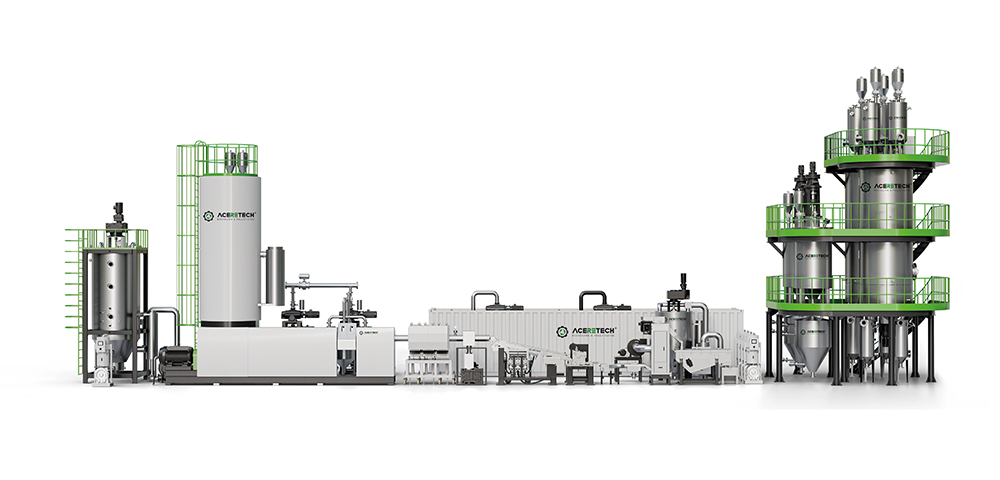

Features:

* The vacuum compaction bin equipped with pre-crystallization drying functionality ensures that the raw materials are thoroughly dried and prevents yellowing of the bottle flakes due to oxidation.

* Precrystallization drying using frictional heat is more energy-saving compared to electric heating.

* A set of three-stage Roots vacuum pumps ensures the effective removal of volatile substances.

* Automatic backwashing waste discharge filters ensure filter accuracy and reduce the frequency of replacement for the melt filter screen.

* Online viscometer for real-time detection of melt viscosity, visualizing the viscosity of the extruded melt.

* Automatic strands cutting and pelletizing saves labor and ensures uniform final chips' dimensions.

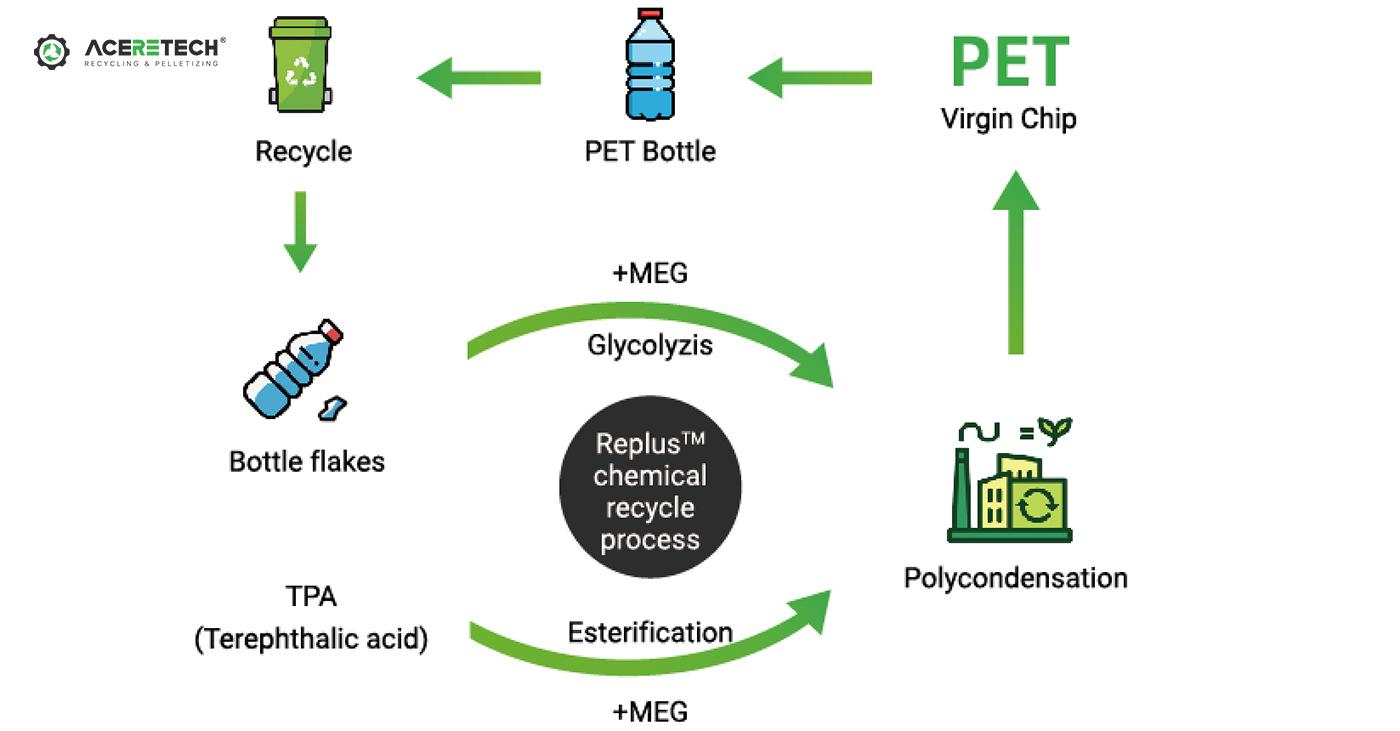

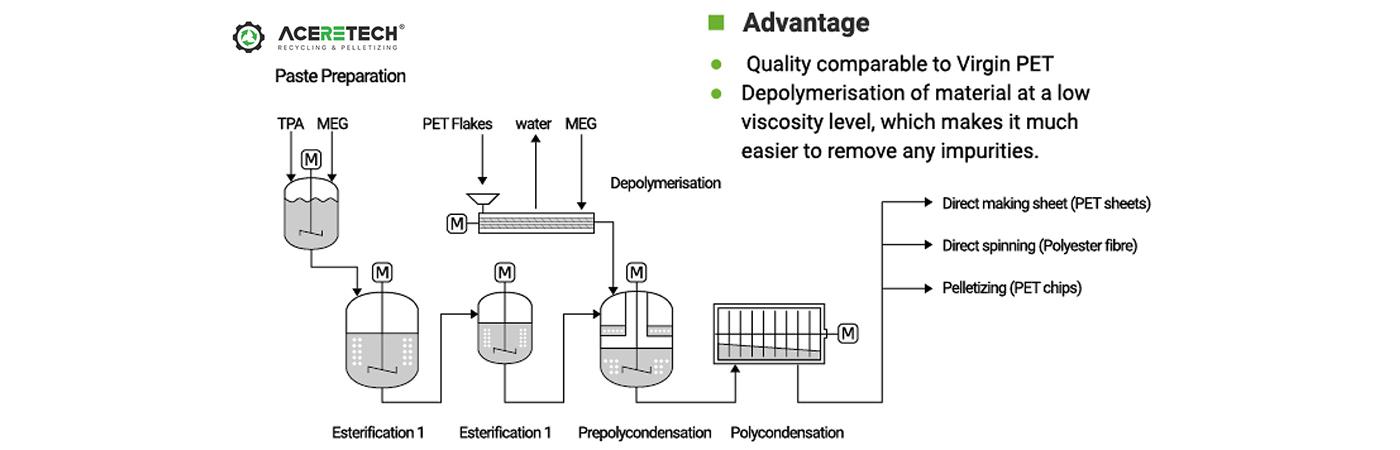

R-PET Chemical Recycling Technology

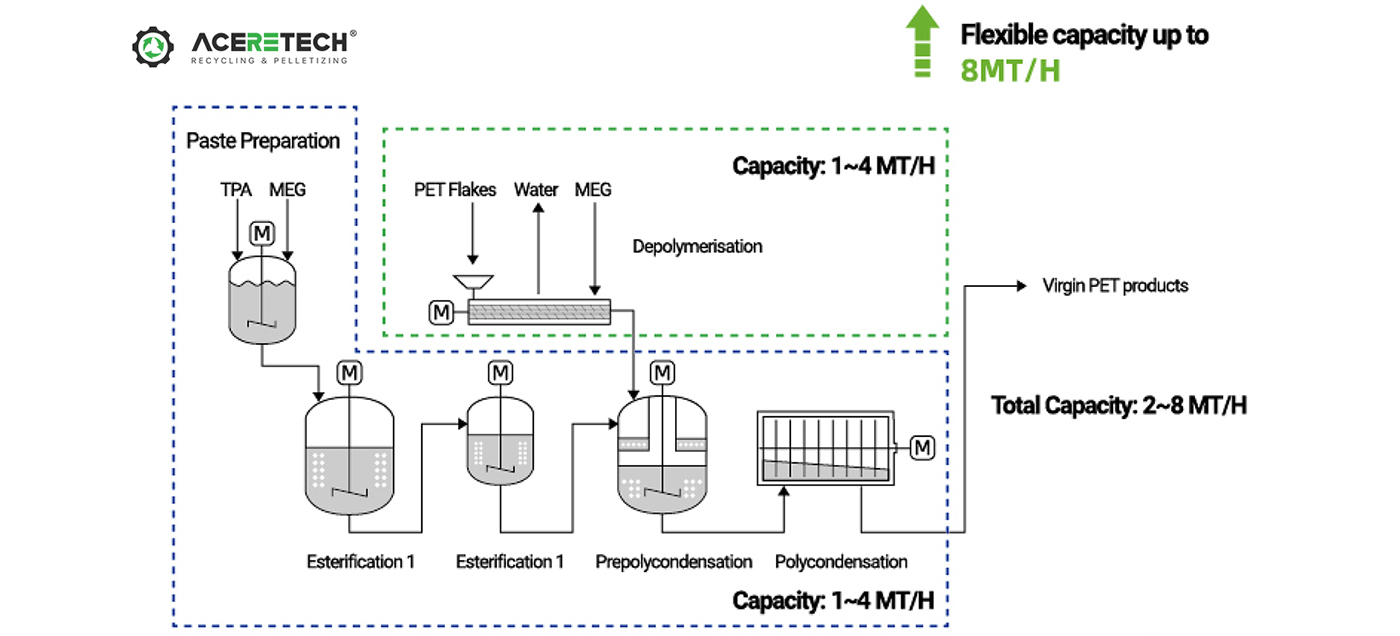

The chemical recycling process is based on PET bottle flakes,which are filtered and adapted in their intrinsic viscosity before being introduced as a melt side-stream back into the prepolymer of the prepolycondensation process.

Chemical Recycling Process

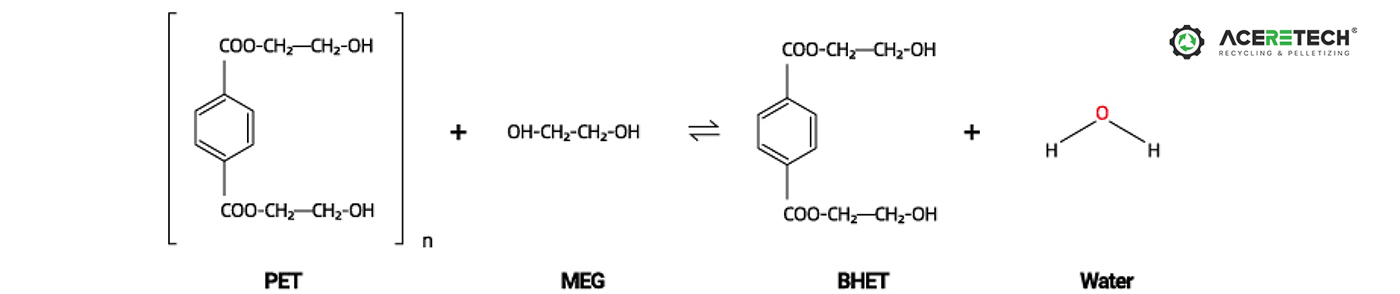

Depolymerisation reaction

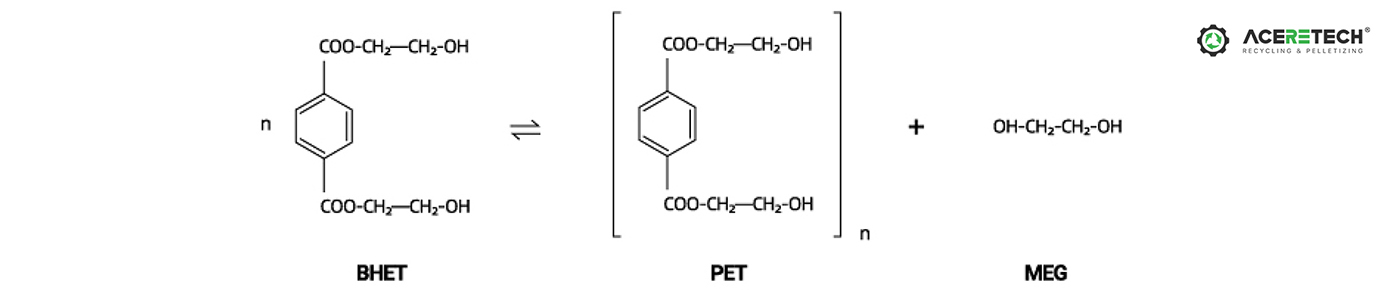

Polycondensation reaction

Flexible production capacity can use up to 50% PET bottles and 50% virgin PET, and also can complete the production of Virgin PET products.

One-Step Solution for R-PET Recycling Applications

The safPET recycling system can be integrated with PET product production lines, such as bottle preform injection molding machines, spinning lines, and packaging tape production lines, to achieve one step online recycling and production of products.This reduces the material handling process, lowers the energy consumption of the entire production line, and thereby improves production efficiency. maximizing the circular regeneration of PET bottles.