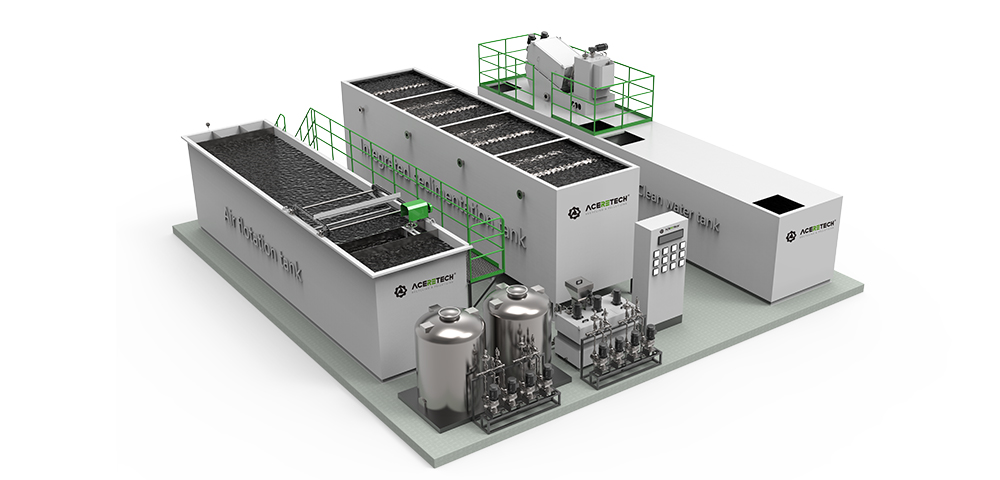

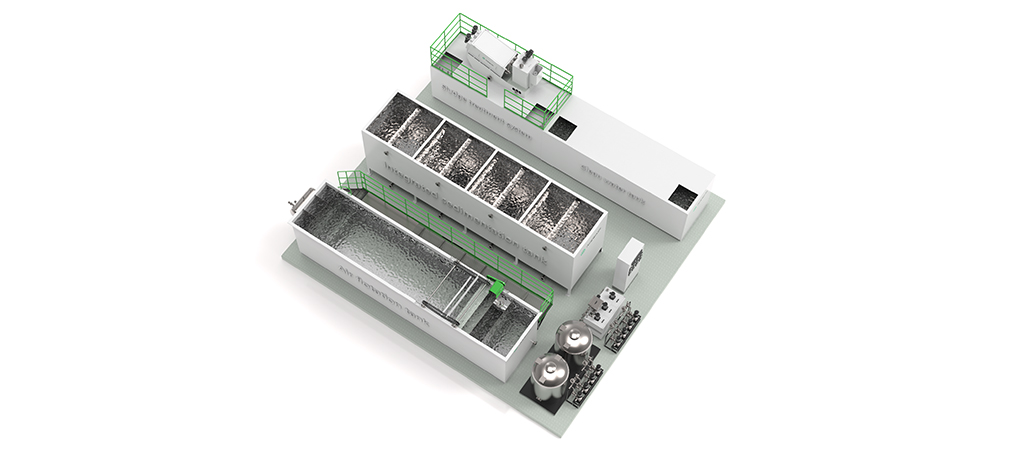

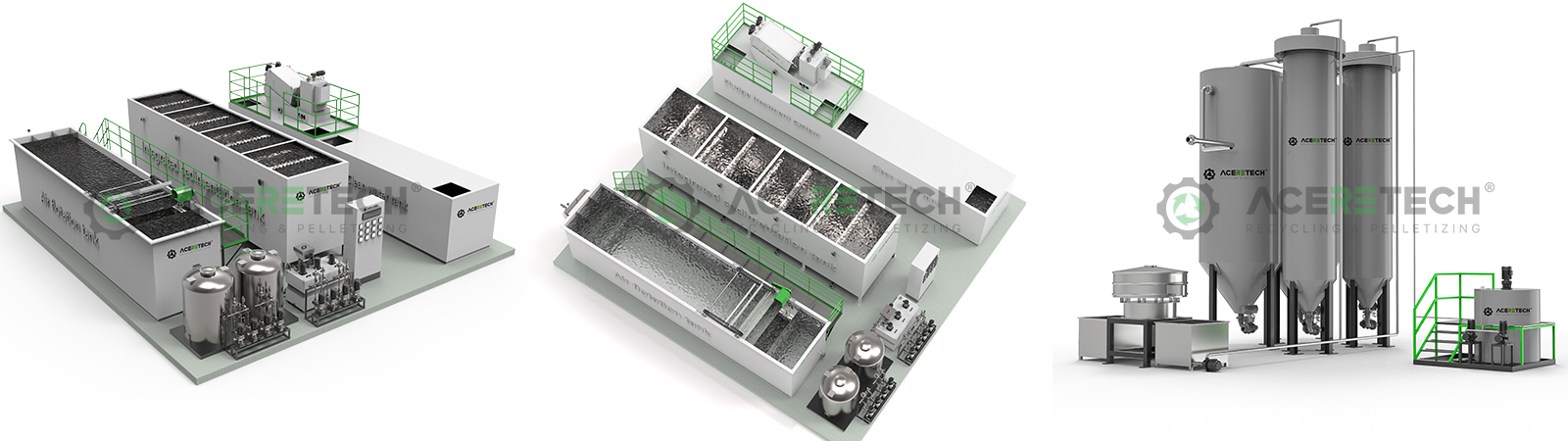

Waste Water Treatment System For Plastic Recycling Line

Waste Water Treatment System For Plastic Recycling Line

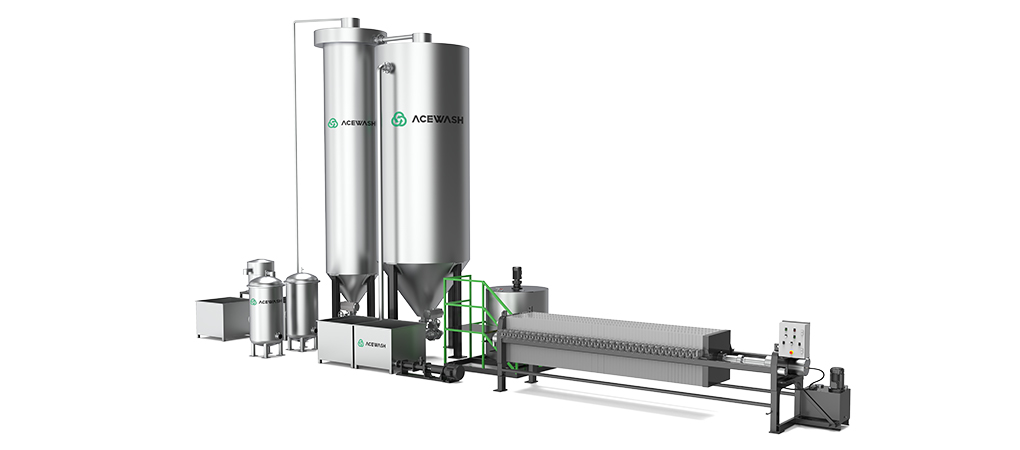

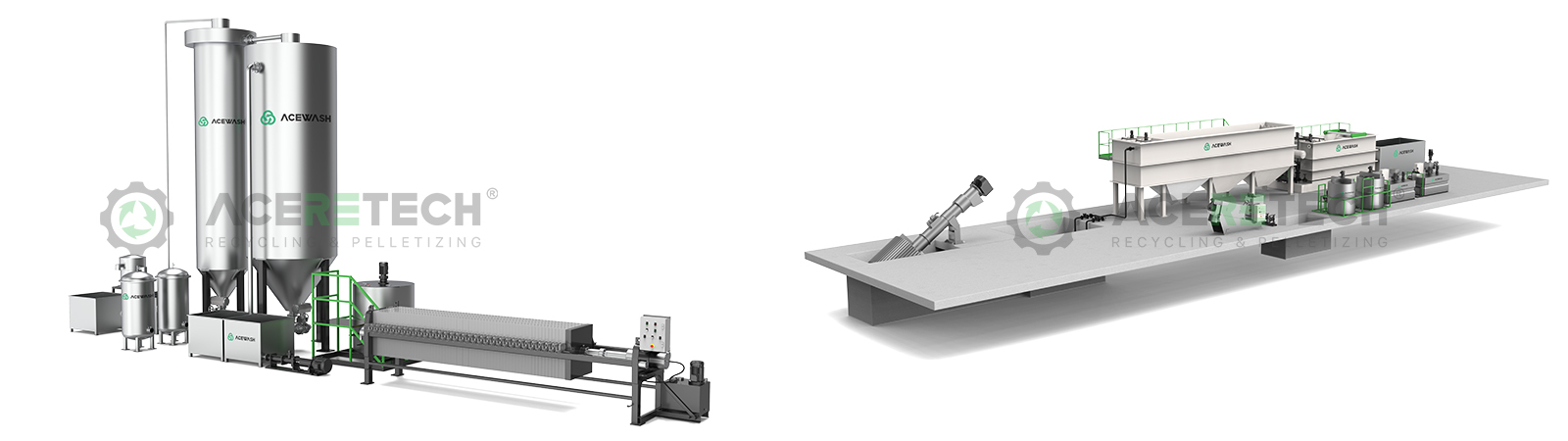

* Efficient

Our systems are able to process large volumes of wastewater quickly,and saving time.High level of automation, automatic proportioning of chemical agent concentration,constant temperature heating of the system.

* Economical

By recycling waste water, cleaning cost is reduced and economic benefits are improved.Without adding any chemical reagents,the recovery of chemical reagents can be realized,reduce the use of chemicals.

* Environmental friendly

Reduce waste water discharge, protect the environment and achieve sustainable development.Wastewater reuse,reducing water consumption and wastewater treatment costs.

On-line recovery technology of brine and alkaline water

Through the online recovery technology of water treatment,80% of the brine and hot alkaline water can be recovered for reuse.

Collection

We collect wastewater at source to ensure full recycling.

Pre-treatment

Remove impurities and pollutants in wastewater through a fine filtration system.

Disinfection

Kill bacteria and viruses in wastewater by using physicochemical methods.

Treatment

Physical and chemical methods are used to remove suspended solids in water.

Recycling

The treated water is regenerated and purified to meet recycling standard and reused for plasticwashing line.