1. Introduction to PP woven bags

PP woven bags, that is, polypropylene woven bags, are a kind of packaging material widely used in chemical, building materials, grain, feed and other industries. It has the characteristics of lightness, toughness, moisture resistance, anti-aging, and high temperature resistance, and is deeply loved by users. However, with the rapid development of my country's economy, the use of PP woven bags has increased year by year, and the problem of handling discarded woven bags has become increasingly prominent. In order to solve this problem, more and more companies have begun to pay attention to the recycling and reuse of PP woven bags.

2. Crushing PP woven bag pelletizing demand

In response to the customer's demand for recycling PP woven bags, crushing PP woven bag pelletizing has become an effective solution. Through crushing, compaction, pelletizing and other processes, discarded PP woven bags are remade into plastic particles to achieve resource reuse. This not only helps to reduce the production costs of enterprises, but also reduces environmental pressure, and has good economic and social benefits.

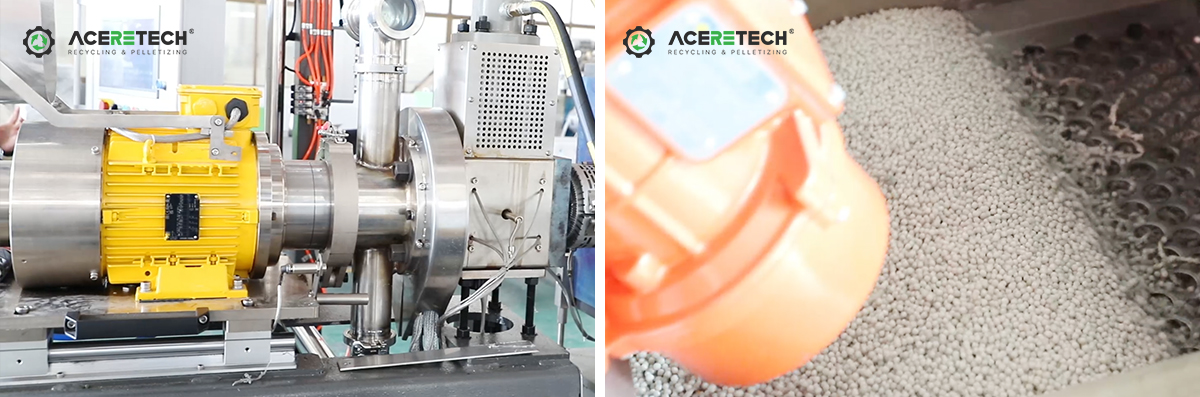

3. ACERETECH recommends - ACS-PRO plastic film three-in-one high-efficiency compaction pelletizer

In order to meet the needs of customers for crushing PP woven bags and granulating, ACERETECH recommends an efficient and stable pelletizing equipment - ACS-PRO plastic film three-in-one high-efficiency compaction pelletizer. The following is the configuration and features of the three-in-one high-efficiency compaction pelletizer recommended by ACERETECH for customers:

Configuration

(1) Pelletizing barrel: 500L, made of high-quality stainless steel, corrosion-resistant and wear-resistant, ensuring a stable and reliable production process.

(2) Screw diameter: 100mm, made of high-strength and high-quality nitrided steel, with good wear resistance and long service life.

(3) Pelletizing method: underwater cutting, fast pelletizing speed, uniform pellet shape, which is conducive to improving product quality.

Features

(1) High efficiency and energy saving: The ACS-PRO pelletizer adopts advanced three-in-one compaction technology, which integrates the three processes of crushing, compaction and pelletizing into one, with high production efficiency and energy saving and consumption reduction.

(2) Easy operation: The equipment adopts an automated control system, which is easy to operate and reduces labor costs.

(3) Strong adaptability: The ACS-PRO pelletizer is suitable for the recycling and pelletizing of various waste plastic films, woven bags and other wastes, and has a wide range of applications.

(4) Environmental protection compliance: During the production process, the equipment strictly implements national environmental protection standards to ensure that emissions meet the standards.

4. Summary

The crushed PP woven bag pelletizing project has good market prospects and development potential. The ACS-PRO plastic film three-in-one high-efficiency compaction pelletizer launched by ACERETECH has become an ideal choice for crushing PP woven bag pelletizing with its advantages of high efficiency, stability and environmental protection. I believe that in the near future, ACERETECH will make greater contributions to the development of the global plastic recycling industry.

Click the link below to view the test video

Crushing PP Woven Bags Three-In-One Efficient Compaction Pelletizer

2025/01/21

in Applications