With the rapid development of the plastic packaging industry, LDPE film, as a common packaging material, has become increasingly important for recycling. According to the needs of Turkish customers, ACERETECH customized a small LDPE film washing line with an output of 1000kg/h, aiming to improve the efficiency of film recycling and promote resource recycling.

LDPE film introduction

LDPE film, that is, low-density polyethylene film, is widely used in food packaging, shopping bags, agricultural mulch and other fields because of its good flexibility, cold resistance and chemical stability. However, if the used LDPE film is not recycled, it will cause serious pollution to the environment. Therefore, the recycling and cleaning of LDPE film has become an important part of the environmental protection industry.

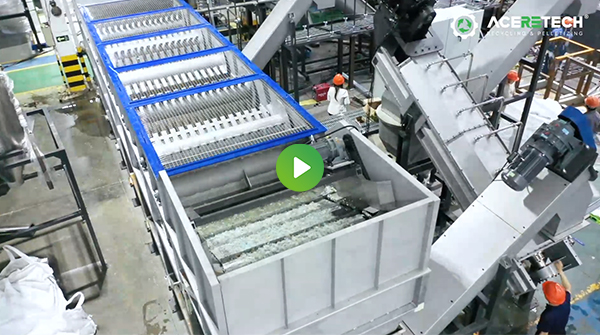

Features of ACERETECH small LDPE film washing line

High-speed friction washing: The high-speed friction washing technology can effectively remove impurities and pollutants on the film and ensure the cleaning effect.

European design and electrical appliances: The washing line adopts European design standards and is equipped with European electrical appliances to ensure the high quality and operation stability of the equipment.

Screw loader: The screw loader system is efficient and reliable, ensuring the continuous operation capacity of the washing line.

Floating tank: The carefully designed floating tank can thoroughly wash the film and ensure the quality of the recycled plastic.

Centrifugal dehydrator: The efficient centrifugal dehydrator can quickly remove moisture from the film and improve the washing efficiency.

High washing efficiency: The washing line can produce up to 1000kg per hour, meeting the production needs of small and medium-sized recycling companies.

Operation stability: The equipment design takes into account the needs of long-term continuous operation, with a low failure rate, ensuring the continuity of production.

Low energy consumption: While ensuring efficient cleaning, the washing line has low energy consumption and reduces production costs.

Localized service

ACERETECH is committed to providing customers with a full range of services, including localized installation, maintenance, and commissioning services. Our team of engineers can provide on-site installation guidance to ensure that the equipment is put into operation quickly and efficiently. At the same time, we provide online guidance services, so that customers can enjoy professional technical support no matter where they are.

Conclusion

The launch of ACERETECH's small LDPE film washing line not only provides an efficient solution for the recycling of LDPE film, but also contributes to the development of the plastic recycling industry. We believe that through continuous technological innovation and service optimization, ACERETECH will help more companies achieve green production and jointly build a sustainable future.

Click the link below to view the factory test video.

LDPE Film Recycling and Washing Line

2025/02/17

in Applications