1. LLDPE stretch film: the "invisible hero" in the packaging field

LLDPE (linear low-density polyethylene) stretch film is a plastic film with high transparency, high tensile strength and high puncture resistance. It is widely used in logistics, warehousing, transportation and other fields. It is used to wrap and package goods to play the role of fixing, dustproof and moisture-proof. However, with the increasing use of LLDPE stretch film, the disposal of its waste has also become an environmental problem that needs to be solved urgently.

2. ACERETECH customized solution: efficient recycling, turning waste into treasure

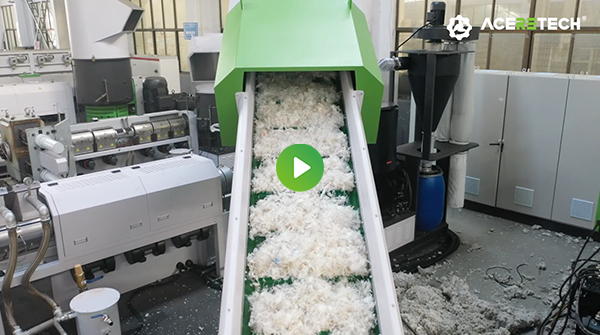

As a professional plastic recycling equipment manufacturer, ACERETECH is well aware of customer needs and is committed to providing customers with customized plastic recycling solutions. For the recycling and processing of LLDPE stretch film, ACERETECH has customized the following efficient recycling and granulation solutions according to the specific needs of customers:

3. Main equipment and process flow

Belt conveyor with metal detection: Used to evenly transport LLDPE stretch film to the production line, detect and remove metal impurities in it, and protect subsequent equipment.

Dust removal device: Used to remove dust and impurities on the surface of LLDPE stretch film to ensure product quality.

Compacting silo with light tube: Used to compact the loose LLDPE stretch film to improve feeding efficiency, and equipped with a light tube to facilitate observation of the material situation.

Brand motor and gearbox: Use motors and gearboxes of internationally renowned brands to ensure stable and reliable operation of the equipment and strong power.

Two-stage single screw extruder: Use a two-stage single screw extruder. After two extrusions, the plastic melt is more uniform and the product quality is more stable.

Intelligent touch screen control system: Use an intelligent touch screen control system to realize automatic control of the production process, easy operation, and one-button start and stop.

Non-stop piston filter: Use a non-stop piston filter to effectively remove impurities in the melt, ensure the purity of the particles, and realize non-stop screen change to improve production efficiency.

Water ring pelletizer: Use a water ring pelletizer to ensure uniform particle shape and smooth surface.

Vibrating dewatering screen: used to remove moisture from the surface of particles.

Air conveying silo: used to store finished particles and realize automatic weighing and packaging.

4. Summary

ACERETECH LLDPE stretch film recycling and granulation solution is an ideal choice for LLDPE stretch film recycling and reuse. This solution has the advantages of high efficiency, environmental protection, and high degree of automation. It can help customers achieve efficient recycling and resource utilization of LLDPE stretch film and contribute to the development of circular economy.

Click the link below to view the factory test video.

LLDPE Stretch Film Recycling and Granulation

2025/03/27

in Applications