The Industrial Process: How Hard Plastics Are Prepared for Recycling

It takes more than simply throwing things in a blue bin to recycle hard plastics. Preparation is key to ensuring that your rigid plastic waste is recycled instead of ending in landfills. The important actions you should take before recycling hard plastics are outlined in this guide, which is based on industry best practices and advice from plastic recycling specialists.

♻️Understanding Hard Plastics

Hard plastics, also known as rigid plastics, include items like:

- Food containers and bottles

- Plastic furniture

- Toys and storage bins

- Automotive parts

- Electronics housings

Unlike flexible plastic films, these items maintain their shape and require different handling in the recycling process.

♻️Steps of Rigid Plastic Recycling

Here's how facilities like Aceretech process rigid plastics through their advanced washing systems:

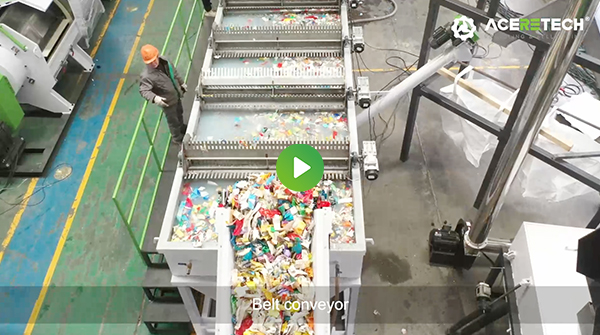

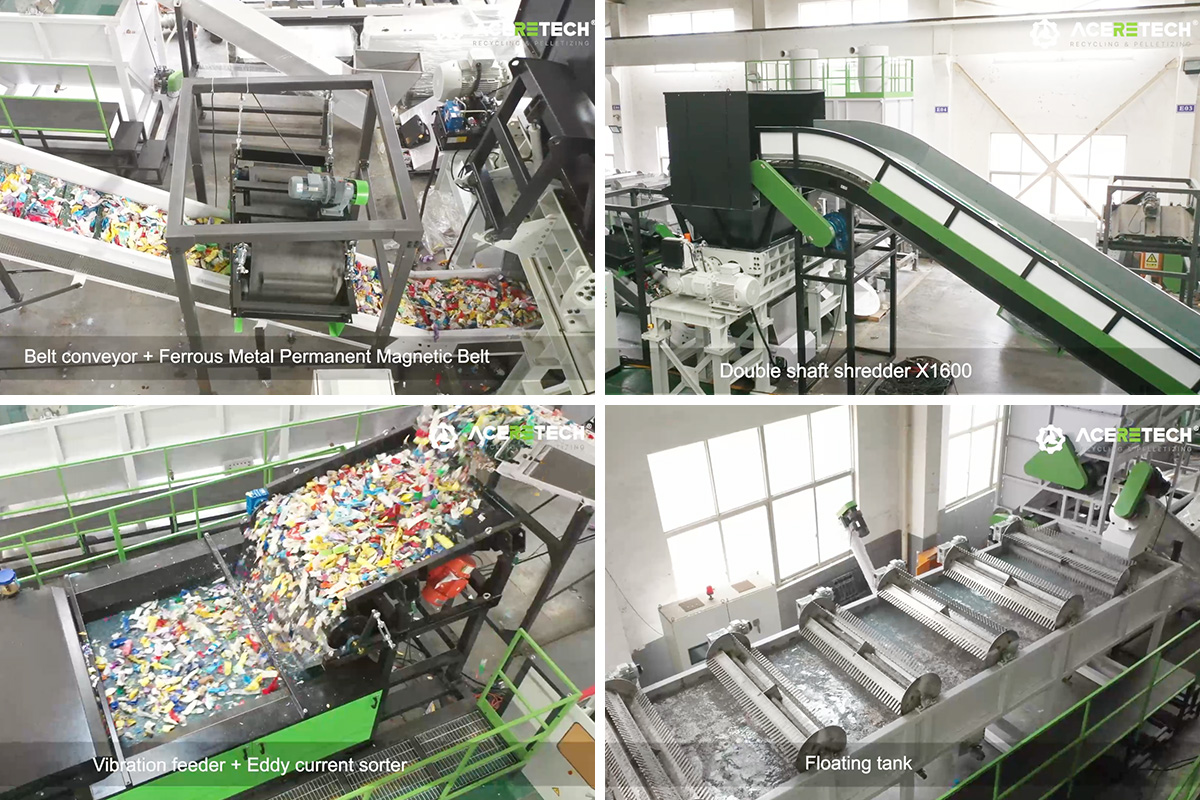

Step 1: Metal Detection and Initial Sorting

Industrial Process:

- A belt conveyor with metal detection automatically removes metal impurities.

- Optical sorters identify and separate different plastic types.

What This Means for You:

✓ Remove metal components (screws, bottle caps, etc.) before recycling

✓ Keep different plastic types separate when possible

Step 2: Size Reduction Process

Industrial Process:

- Double shaft shredder breaks large rigid plastics into smaller pieces.

- GH crusher further reduces the material to uniform fragments.

What This Means for You:

✓ Flatten large containers to help with initial processing.

✓ Remove non-plastic attachments that could damage equipment.

Step 3: Deep Cleaning System

Industrial Process:

- Floating tanks provide preliminary and secondary rinsing.

- European high-speed friction washers thoroughly remove stains and adhesives.

- The centrifugal dehydrator removes moisture after washing.

What This Means for You:

✓ Rinse containers at home to remove food residues

✓ Remove labels when possible (though modern systems can handle some)

Step 4: Final Purification

Industrial Process:

- Vibration feeder ensures even material distribution

- Eddy current sorter removes non-magnetic metals

- Multiple filtration stages eliminate remaining impurities

What This Means for You:

✓ Separate materials properly to avoid contamination

✓ Never recycle hazardous material containers

Step 5: Preparation for Reuse

Industrial Process:

- A packaging system with a dust collector prepares clean material

- Processed plastic flakes are ready for pelletizing and manufacturing

What This Means for You:

✓ Ensure your recyclables are dry before collection

✓ Follow local guidelines for proper disposal

♻️Why This Industrial Process Matters

Understanding these industrial steps helps explain why proper consumer preparation is crucial:

- Metal removal prevents damage to expensive sorting equipment

- Pre-cleaning reduces water and energy use in industrial washing

- Proper sorting maintains material quality for higher-value recycling

- Contamination control ensures the final product meets manufacturer standards

Properly preparing hard plastics for recycling maximizes their reuse potential and reduces landfill waste. These actions—determining the type of plastic, eliminating impurities, cleaning thoroughly, and confirming local regulations—will help create a more efficient recycling system.

Team Aceretech can provide you with more information about waste plastic recycling machines & related procedures.