I. PP woven bags: Environmental challenges brought by widespread use

PP woven bags are packaging bags woven from polypropylene (PP) flat wires. Due to their high strength, light weight, corrosion resistance, and low price, they are widely used in the packaging of food, fertilizers, cement, chemical raw materials and other products. However, with the increasing use of PP woven bags, the environmental problems caused by their disposal are becoming increasingly prominent. Traditional landfill and incineration methods not only occupy land resources, but also cause soil and water pollution, and even release harmful gases, endangering human health.

II. Pelletizing and recycling: an effective way to recycle PP woven bags

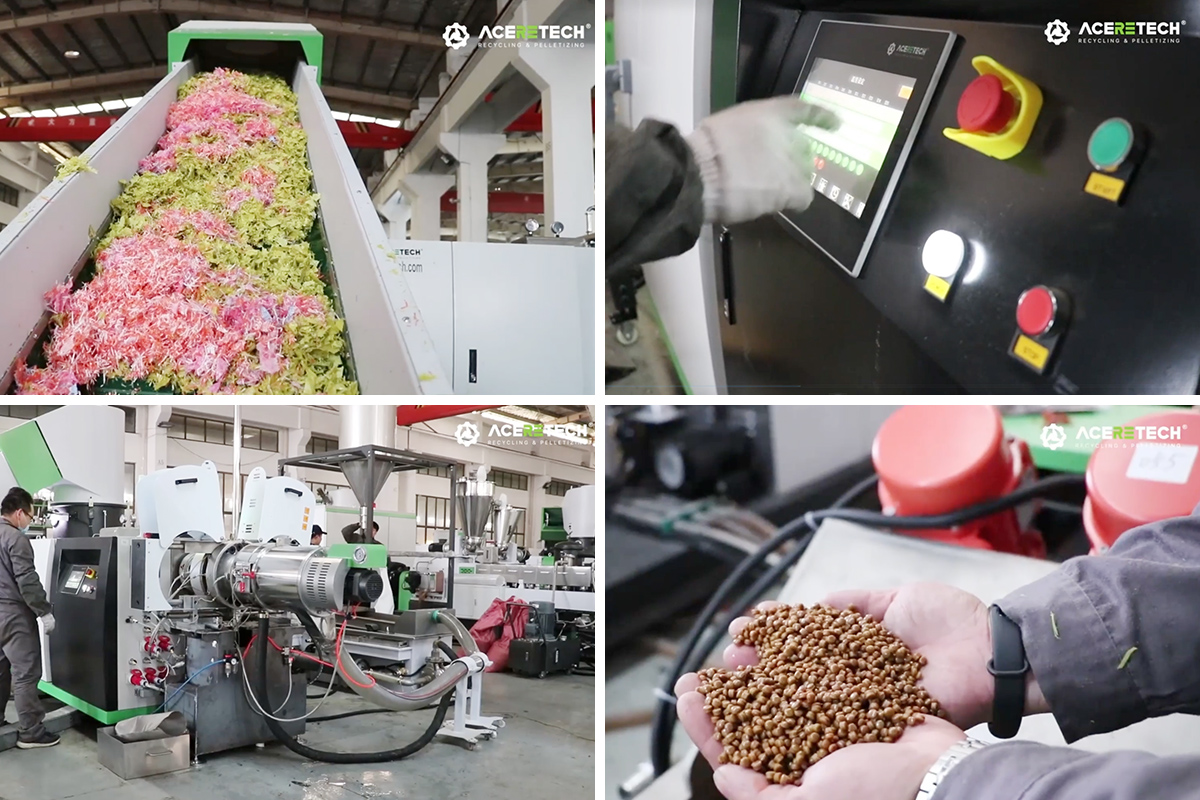

Faced with the environmental challenges brought by PP woven bags, pelletizing and recycling have become an effective way to recycle resources. By crushing, washing, melting, extruding, and pelletizing the discarded PP woven bags, they can be processed into recycled plastic particles, which can be used again to produce new plastic products, realizing the recycling of resources and reducing pollution to the environment.

Ⅲ. ACS-H plastic pelletizer produced by ACERETECH: efficient, intelligent and durable pelletizing solution

According to the European customers' demand for high-quality recycling and pelletizing of PP woven bags, ACERETECH recommended the ACS-H plastic pelletizer independently developed and produced to customers. The equipment integrates a number of advanced technologies and provides an efficient, intelligent and durable solution for the pelletizing and recycling of PP woven bags.

1. Belt conveyor, efficient and stable: ACS-H adopts belt conveyor to evenly and stably convey PP woven bags to the extruder, ensuring the continuity and stability of the production process and improving production efficiency.

2. Intelligent control system, easy to operate: The equipment is equipped with an advanced intelligent control system and a touch screen interface. The operation is simple and intuitive, which can realize automated production and reduce labor costs.

3. Dual alloy single screw extrusion, wear-resistant and corrosion-resistant: ACS-H adopts dual alloy single screw extrusion technology. The screw and barrel are made of special alloy materials with excellent wear resistance and corrosion resistance. It can effectively extend the service life of the equipment and ensure that the output does not decrease within two years.

4. Vibrating screen, uniform pellets: The equipment is equipped with a vibrating screen to screen the extruded plastic strips, remove impurities and oversized pellets, and ensure that the final product has uniform pellets and stable quality.

5. Weighing silo, precise measurement: ACS-H is equipped with a weighing silo, which can accurately measure the raw materials to ensure the stability of the production process and the consistency of product quality.

IV. The significance of plastic pelletizer:

Plastic pelletizer can not only turn waste plastics into treasures and realize the recycling of resources, but also reduce the consumption of petroleum resources and reduce carbon emissions, which has important economic and environmental benefits.

V. Conclusion:

ACERETECH ACS-H PP plastic pelletizing machine provides an ideal solution for the pelletizing and recycling of PP woven bags with its high efficiency, intelligence and durability. It is believed that with the promotion and application of this equipment, it will effectively promote the resource utilization of PP woven bags and make positive contributions to environmental protection and sustainable development.

Click the link below to view the PP woven bag workshop recycling pelletizing test machine video.