In the plastic packaging industry, PE film is a widely used material, and its recycling and reuse is of great significance for environmental protection and resource circulation. ACERETECH, as a professional plastic recycling equipment manufacturer, has launched a set of efficient PE film recycling and washing lines, which aims to completely remove ink, adhesives, dust and other impurities on the film and realize the clean recycling of PE film.

Introduction to PE film

PE film, also known as polyethylene film, is widely used in food packaging, commodity packaging, agricultural covering and other fields because of its good chemical stability, low temperature resistance and processing performance. However, the used PE film is often stained with pollutants such as ink and adhesives, and needs to be treated by professional cleaning equipment before it can be put back into the production cycle.

Features of ACERETECH PE film recycling and washing line

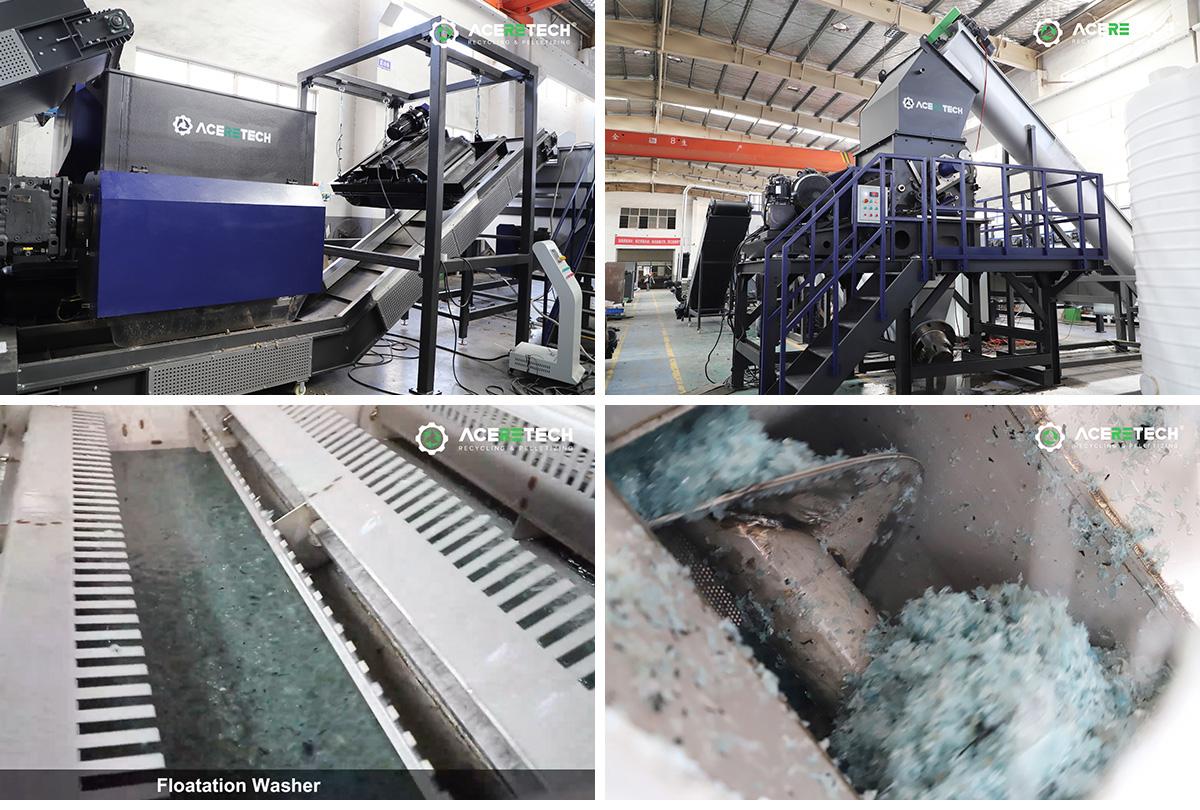

HS shredder: HS shredder shreds the PE film initially for subsequent cleaning.

Belt conveyor with metal detection: The shredded film passes through the belt conveyor with metal detection to automatically remove metal impurities and ensure the cleaning quality.

Equipped with two floatation washers: The film is washed in two floatation washers to initially remove surface pollutants.

Screw loader: The screw conveyor evenly delivers the cleaned film to the next link.

Equipped with two high speed friction washing: Two high speed friction washing equipment are used for high-speed friction washing to effectively remove stubborn stains.

Equipped with two squeezers: The cleaned film passes through two squeezers to remove excess water.

20cm³ silo: The squeezed PE film is stored in a 20cm³ silo for subsequent processing.

Fully automatic intelligent washing: The entire washing line adopts a fully automatic intelligent control system to reduce manual intervention and improve washing efficiency.

Washing effect

ACERETECH's PE film recycling and washing line can effectively remove ink, adhesives, dust and other impurities on the film, ensure the quality of recycled PE film, and meet the needs of the high-end market.

Customized service

ACERETECH provides customized cleaning line solutions based on different PE film types and customer needs. Our professional team will design the most suitable cleaning process according to the specific situation of the customer.

Certification and standards

ACERETECH's plastic recycling equipment has obtained many international certifications such as CE, FDA, ISO, CSA, etc., ensuring the safety and reliability of the equipment.

Conclusion

ACERETECH's PE film recycling and washing line, with its high efficiency and stable performance, provides strong support for the recycling and reuse of PE film. We are committed to helping customers achieve green production through technological innovation and service upgrades, and jointly promote the sustainable development of the plastic recycling industry.

Get a Quote Now!

Click the link below to view the factory test video