article paragraph

Ⅰ Introduction of plastic shredder

Ⅱ Scope of application

Ⅲ Performance characteristics of plastic shredder

Introduction of Plastic Shredder

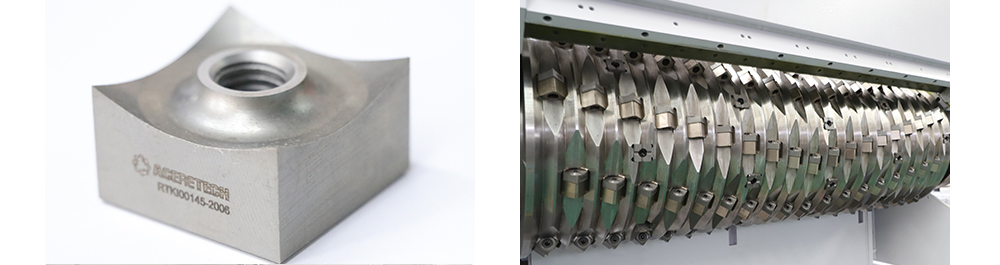

Plastic shredder is a kind of solid waste volume reduction machinery environmental protection shredder equipment, which is used to shred waste plastic products and materials, which is conducive to plastic recycling and recycling of plastic particles. The plastic uniaxial shredder uses the interaction between the moving knife and the fixed knife, and controls the discharge particle size through the screen, and shreds, shears and squeezes the material to process the material to a smaller size. It is often used for fine shredding of various solid wastes, and can process materials to smaller sizes at one time. Bottles, oil bottles, gasoline bottles, plastic barrels, plastic trays, plastic baskets, plastic pipes and other plastic products, involving a wide range of fields, easy to operate, low noise and other advantages. The discharge particle size of the plastic shredder is generally 10-50 mm. The plastic shredder mainly includes a main machine, a production line, a magnetic separation equipment, a conveyor, and a motor. Eslite supplies powerful plastic single-shaft shredders, small plastic shredders, and plastic pipe shredders. We have specialized machine design engineers, according to the needs of users, material characteristics, and hourly output requirements, the shredder The overall design and planning of the cutter head diameter, the number of cutter teeth, the model of the motor and the reducer.

Scope of application

Widely used in waste plastics, waste rubber, wood, paint buckets, waste home appliance shells (plastic shells, metal shells), large tires, large nylon materials, plastic head materials, large fishnets, large pipes, fibers, paper, industrial waste, Electronic waste, construction waste and other bulky waste.

Performance characteristics of plastic shredder

1. Thick and heavy moving knives have high crushing efficiency. The knives are all cast with alloy steel, which is sturdy and has a long service life.

2. The frame plate is thick, can resist high torque and is very strong.

3. Adopt microcomputer (PLC) automatic control, set start, stop, reverse and overload automatic reverse control functions.

4. The equipment has the characteristics of low speed, high torque, low noise, and dust that can meet environmental protection standards.

5. Easy to adjust, low maintenance cost, economical and durable.

6. The thickness of the tool and the number of claws can be changed according to different materials, the fixed knife can be disassembled independently, and the wear resistance is strong

7. Soft milling shredding, low noise, low energy consumption, uniform shredding and pulling degree.

8. The hydraulic pushing device adopts Taiwan brand. All contact control electrical appliances adopt German Schneider.

9. The main shaft has high strength, strong anti-fatigue and impact resistance, high load resistance, long life, dust-proof, waterproof and anti-fouling, which ensures the continuous and stable operation of the machine.