Waste household appliances are entering the peak period of scrapping. Plastic is an important part of waste household appliances, and its weight ratio is as high as 30-40%, which has exceeded the output of metal materials in terms of output and volume. Therefore, the recycling of waste plastics has become a concern in the household appliance recycling industry. Plastics commonly used in home appliances are mainly thermoplastic materials such as polyethylene (PE), polypropylene (PP), polystyrene (PS), ABS resin, polyvinyl chloride (PVC), etc. and some thermosetting resins such as polyurethane. Resin foam, nylon and plastics added with glass fiber, etc. Among them, the five major materials of PE, PP, PS, PVC and ABS account for more than 85% of the whole household appliance plastic products.

Plastics in waste household appliances are currently mainly recycled through recycling. There are many ways to recycle plastics, the most important ones are mechanical recycling, chemical recycling, energy recycling and composting. The mechanical recycling method is also known as the raw material recycling method. The molecular structure of waste plastics basically does not change. There are two methods: direct recycling and melting recycling. The cost of recycling plastics is relatively low. Therefore, the melt recycling granulation method has become the main method of the household appliance plastic recycling industry.

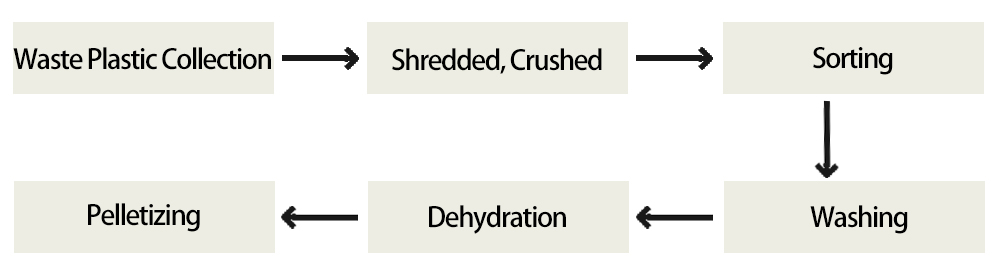

The main process of plastic granulation technology process is:

Due to the complex shapes and different sizes of waste plastics, especially some larger waste products, they must be crushed into fragments or small pieces of materials of a certain size by means of pulverization, grinding or shearing, so that they can be recycled. . Powerful shredders, plastic shredders, plastic shredders, these types of plastic shredders have their own characteristics.

The sorting technology of waste plastics is to select similar plastics from waste plastics. Separation and screening work is an important process for the recycling of waste plastics. The sorting method of plastic waste is mainly determined by its physical properties, including particle size, density, electromagnetic properties and color. Their physical properties are different, and their separation methods are also different. The sorting technology of waste plastic mixture can be divided into dry method and wet method. It is generally believed that the wet method is easier to obtain higher sorting accuracy than the dry method. Optical separation, electrical separation, wind separation, density separation, flotation, etc. have all been applied to different degrees in waste plastic separation.

Unobstructed waste plastics are contaminated with oil, garbage, sediment, etc. to varying degrees. These impurities will seriously affect the quality of recycled plastic products. Therefore, waste plastics must be cleaned. The cleaning methods of waste plastics include manual cleaning, mechanical cleaning and ultrasonic cleaning. Among them, mechanical cleaning is a more common and mature cleaning method. There are two types of mechanical cleaning: intermittent and continuous. The cleaning process of waste plastics is divided into three processes: pre-wash, main wash and rinse.

The drying technology of waste plastics is an operation to vaporize and remove volatile components such as moisture and solvents in the material. It is a very important part in the plastic processing process, because many resins are easy to absorb moisture at room temperature, making their moisture content high. Therefore, it must be dried before molding, otherwise the molded product will have quality problems such as air bubbles and strength reduction, and become unqualified products. There are many drying methods for plastics, and the appropriate drying device and drying conditions can be selected according to the characteristics of the material, the shape, the change of the material during the drying process, and the drying mechanism. At present, the main drying methods are convection drying, vacuum drying and infrared drying.

Waste plastics generally need to be granulated according to the characteristics of the resin and the requirements of molding conditions before molding. The same type of plastic may have different granulation processes, and different types of plastics may also use the same granulation process under appropriate conditions. Since the plastics in recycled household appliances are often a mixture of PS, ABS, PP, etc. The best way is to granulate by adding special compatibilizer mixed waste plastic into co-rotating twin-screw extruder. In this way, compatibilizer-modified blended recycled plastic particles can be produced, and the diameter of the particles in the granulation process can range from coarse to ultra-fine particles. The advantage of this method is that there is no need to separate the mixed waste plastics, saving manpower and energy for sorting, and the plastic products made from the obtained plastic particles not only have improved performance, but also have excellent surface gloss.

The mechanical direct utilization of waste plastics is still one of the best methods. After the waste plastics are separated, cleaned, dried, and crushed, certain additives are added, and then plastic particles are made to be processed into new plastic products. method is the most worthy of use. At present, the process of plastic granulation of waste household appliances in my country is relatively mature, but there are still many problems, which can only be solved through practice. Home appliance plastic granulation is one of the most environmentally friendly methods of home appliance plastic disposal, and it is also one of the methods to give full play to the best value of waste plastics. Therefore, waste plastic granulation will become the most important process for waste plastic treatment.

Description of waste plastic granulation process

2021/03/03