♻️ What is PET Recycling?

PET product varieties also expanded from the initial polyester staple fiber to polyester staple fiber, polyester filament, polyester bottles, polyester film, nonwoven fabrics, engineering plastics and composite multi-functional products, such as many series of hundreds of products and thousands of specifications. Due to the increasing social demand, PET polyester production has grown rapidly. Since 2003, the global production capacity of PET has been expanding at an average annual rate of about 9%, and in 2005, the production capacity has reached about 54.7 million tons with an output of 41 million tons, and by 2008, the global PET production capacity reached 67 million tons with an output of over 50 million tons.

At present, PET products are mostly disposable consumer products, and with them comes a large amount of waste PET materials. Waste PET materials are chemically inert and not easily degraded by air or microorganisms in a short period of time, occupying a lot of space and causing "white pollution". The current task of protecting the ecological environment is urgent, and the recycling of used PET materials is beneficial to environmental protection, resource conservation and sustainable development. The recycling of waste PET beverage bottles can not only reduce environmental pollution, but also turn waste into treasure and gain huge economic benefits from it. With the popularity of non-fiber PET and other packaging products, the technology of PET recycling and reprocessing has emerged in large numbers. The continuous and rapid growth of PET packaging consumption has created an urgent need to increase the recycling and utilization of PET waste, and the recycling technology of PET material has been innovated.

Article ContentsⅠ.PET recycling and reclamation methodsⅡ.The main innovation point of screw extrusion pelletizing

Ⅰ.PET recycling methods

The source of waste polyester mainly has two parts, part of the production and processing of waste, trimmings; the second part is the waste polyester packaging, such as polyester bottles, polyester film, etc.. The first waste polyester is cleaner, can be directly reused; the second waste often with pollutants, must be separated first to remove pollutants and additional materials to be recycled.

To bottle-level PET waste, for example, PET polyester bottle recycling methods are mainly physical recovery method and chemical recovery method, the following we mainly introduce the physical recovery technology and its application.

1. Physical recycling technology

Physical recycling, also known as mechanical recycling, is a relatively simple process, mainly through the method of melt granulation, and there is no obvious chemical reaction in the process. At present, the proportion of physical recycling accounts for about 80 %.

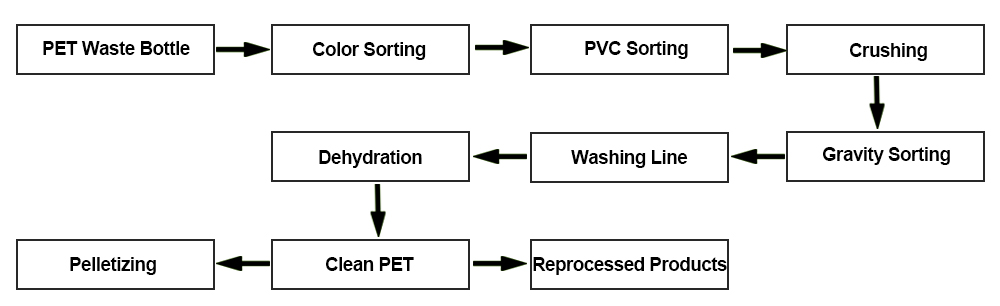

Traditional physical recycling methods are mainly of two types, one is the simple shredding of waste wire, waste blocks, removal of impurities, cleaning, regeneration through the screw extruder pelletizing.

The other is to break the old bottles into pieces, dry, crystallize, plasticize, filter, and then pelletize.

2. Application of PET plastic particles

PET pellets generated after processing are used to make PET-related products, such as chemical fiber textile materials, PET sheet materials, engineering plastic injection materials, etc. The only weak link is the technology of adhesion of PET pellets, and the ability of adhesion is directly related to the performance of recycled PET pellets. The working principle of our LSP/SSP equipment has completely broken through this technical bottleneck and opened up the space for the value of recycled PET pellets to be improved. The equipment applies a series of high and new technologies, which can fully increase the characteristic viscosity of PET during recycling and improve the quality of recycled pellets to meet the relevant standards of new PET materials. By combining the characteristics of physical and chemical methods, the molten state of the molten state by adding chain extenders to make the degraded molecules undergo chain expansion reaction and re-chain into large molecules, thus significantly improving the performance of recycled PET pellets.

Ⅱ.The main innovation point of screw extrusion pelletizing

a. The use of a reactive extruder with high aspect ratio, which can significantly increase the characteristic viscosity of polyester bottle material.

b. High vacuum reaction polycondensation reaction and melting and mixing of materials are realized simultaneously in the screw extruder, which greatly saves energy consumption.

c. Low pollution, continuous production, large processing capacity and objective economic benefits.