I. Introduction

The plastic pelletizing machine processes plastic waste through a series of steps:

A plastic pelletizing machine is a piece of equipment used to convert plastic waste into small, uniform pellets that can be used in the manufacturing of new plastic products. The machine is designed to process plastic waste by cutting it into small pieces, which are then melted and formed into the desired shape and size. Once the plastic has been melted and formed, it is solidified and cut into small pellets for use in the production of new products. Pelletizing machines are commonly used in the plastic recycling industry to help reduce waste and improve sustainability, as well as lower production costs and improve efficiency for manufacturers.

II. The role of plastic pelletizing machine

The plastic pelletizing machine processes plastic waste through a series of steps:

Shredding: The plastic waste is first fed into a shredder, which cuts the material into small pieces, typically around 2-5 cm in size. This creates a consistent feedstock for the next steps in the process.

Melting: The shredded plastic material is then melted in a melting chamber or extruder. The melting temperature and pressure vary depending on the type of plastic being processed.

Filtering: Once the plastic is melted, it goes through a filtering system that removes any contaminants, such as dirt, debris, or other impurities.

Cutting: After the plastic has been filtered, it is extruded (squeezed) through a die to form the pellets. The pellets are then cut to the desired length and cooled.

Sorting: The final step is to sort the pellets by size and quality, to ensure they meet the specifications needed for the intended application.

This process allows manufacturers to recycle plastic waste and turn it into a useful raw material for new plastic products. Moreover, this process helps reducing plastic waste in the environment and contributing to a more sustainable future.

Ⅲ. Types of plastic pelletizing machine

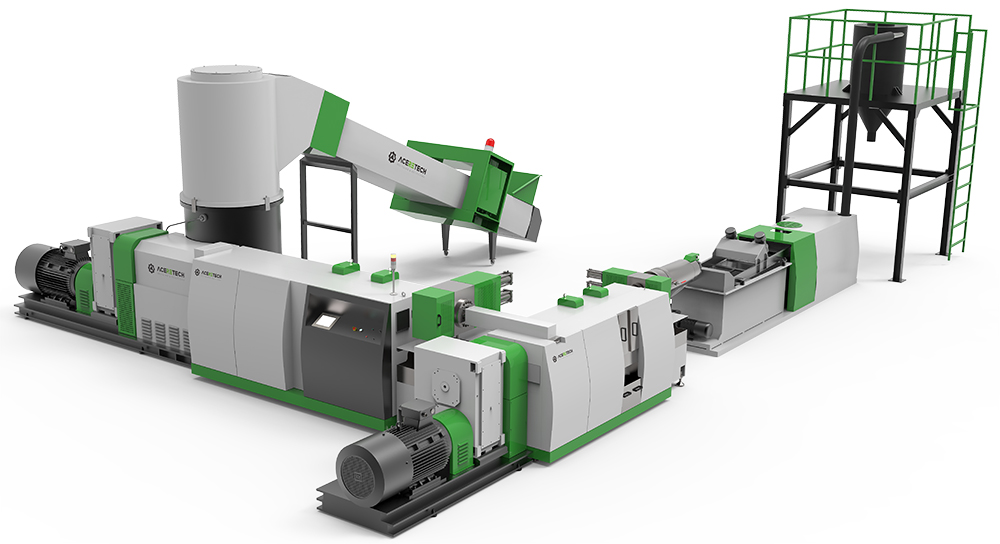

ACS Cutter Compactor Plastic Recycling Pelletizing System

The ACS-H TM series compacting and pelletizing system combines function of crushing, compacting, plasticization and pelletizing to One step. Applied in the plastics recyclng and pelletizing process. ACS-H TM system is a reliable and efficiency solution for plastics film, raffias, filaments, bags, woven bags and foaming materials re-pelletizing.Lower investment for a high performance machine. It can provide higher output but with lower energy consumption.

Application: PE,PP,PS,ABS,XPS,EPS,PVB.

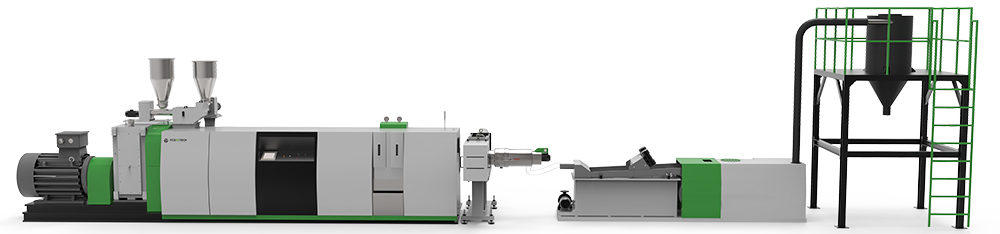

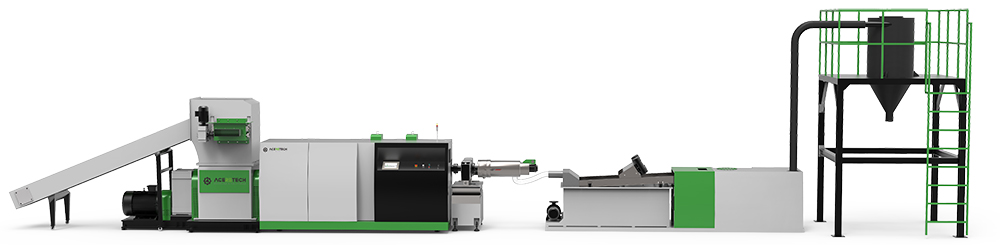

ACSS double stage cutter compactor recycling pelletizing line

The ACSS-H TM series compacting and pelletizing system combines function of crushing, compacting, plasticization and pelletizing to One step. Applied in the plastics recyclng and pelletizing process. ACSS-H TM system is a reliable and efficiency solution for plastics film, raffias, filaments, bags, woven bags and foaming materials re-pelletizing.

The final product produced by the ACSS system is in pellet form and can be placed directly into the production line for blown film, tube extrusion and injection molding.

It consists of two sets of Single-Screw Extruders , suitable for printing ink heavy, high moisture content, poor fluidity and temperature sensitive, high impurity content materials which requires the double filtration system, multiple exhaust and other higher requirements, and a longer process.

Application: PE,PP,PS,ABS,XPS,EPS,PVB.

ASE Single screw extruder recycling machine

The ASE series single screw extrusion and pelletizing system is a specialized and reliable system, suitable to the recycling and re-pelletizing job of rigid plastic scrap. It combines function of plasticization and pelletizing to one step and is ideal for crushed regrinds or flakes of PE/PP/ABS/PS/HIPS/PC etc.

Final productions produced by ASE single screw extrusion line are in the form of pellets/ granules, can directly put into the production line for film blowing, pipe extrusion cand plastics injection, etc.

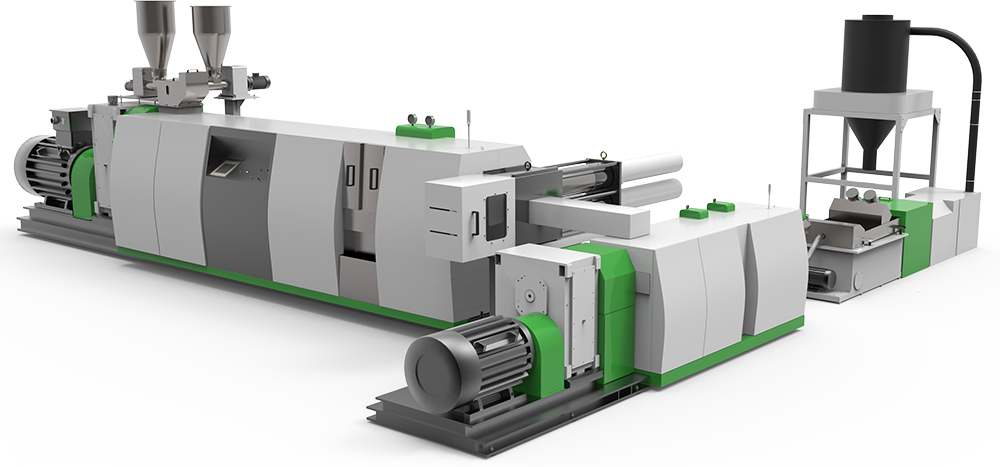

ADS Double Stage Cutter Compactor Recycling Pelletizing Line

The ADS series single screw extrusion and pelletizing system is a specialized and reliable system, suitable to the recycling and re-pelletizing job of rigid plastic scrap. The characteristic of the single-screw two-stage granulator is that it is suitable for materials with more impurities, higher moisture content and large output. At the same time with a forced feeder. It combines function of plasticization and pelletizing to one step and is ideal for crushed regrinds or flakes of PE/PP/ABS/PS/HIPS/PC etc.

Final productions produced by ADS single screw extrusion line are in the form of pellets/ granules, can directly put into the production line for film blowing, pipe extrusion cand plastics injection,etc.

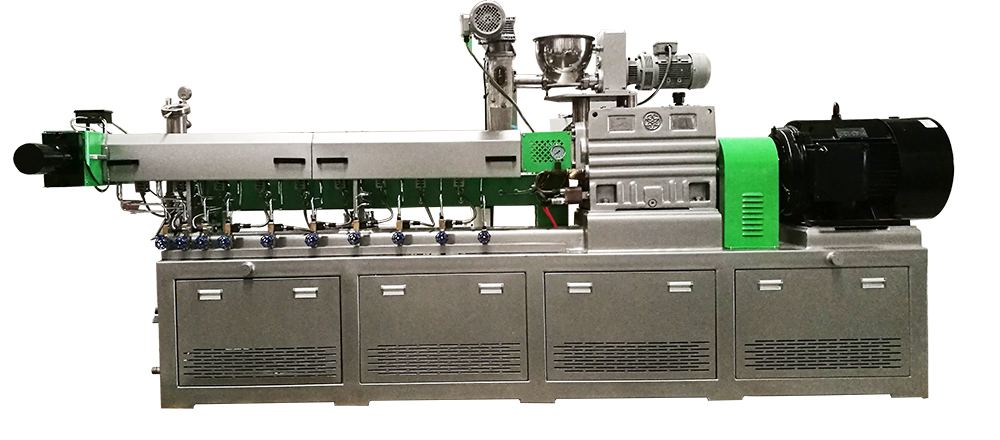

ATE Parallel Twin-Screw Extruder

ATE series parallel twin screw extruder is driven by motor, torque distribution gearbox, processing part, temperature control device, mold part and downstream grain cutting system.

ATE twin screw extruder adopts the principle of modular design and standardized production of components, so as to present stable and reliable performance.

With the principle of modularization, ATE series extruding machines can provide highly customizable solutions according to customers' process and special requirements. Based on different output torque levels, there are two types of ATE extruders: basic type and efficiency type.

ATE co-rotating twin screw extrusion machinery combines a variety of cutting systems, such as water strands cutting system, die surface cutting system and underwater cutting system.

Relay control and PLC control are both used in ATE electrical control system. All key electrical components are European branded to ensure significant stable performance of the control system.

ASP Single Screw Extrusion Line for Shredding and Pelletizing for In-plant Recycling

The ASPTM series shredding and pelletizing system combines function of shredding, crushing, enforcing feeding, plasticization and pelletizing in one program.

Applied in the plastics recycling and pelletizing process, ASPTM system is a integrated and cost-saving solution for every kind of plastic scrap, such as film, raffia, trim, purge, hollow part, bottle and foaming material in plant recycling.

There are different types of plastic pellets available, some of which are:

Strand pelletizing: This is a popular method where plastic strands are produced by extruding melted plastic through a die. The strands are then cooled and cut into pellets.

Underwater pelletizing: This method involves cutting the extruded plastic product into pellets underwater, where it is cooled by water before being dried.

Die face pelletizing: This is a method where melted plastic is extruded through a die and is then cut into pellets by a rotating blade as it exits the die.

These are just a few examples of the types of plastic pelletizing machines available. The choice of machine will depend on various factors such as the type of plastic to be processed, the required throughput, and the desired pellet size and shape.

Ⅳ. The benefits of using a plastic pelletizing machine

Plastic granulators offer many benefits for plastic recycling and processing, some of which are:

Increase in efficiency: Plastic granulators can process large quantities of plastic scrap at a time, which results in faster and more efficient processing.

Consistent output: Using a plastic granulator ensures consistent output of uniform sized plastic pellets, which can be re-used in manufacturing.

Reduction of waste: A plastic granulator reduces plastic waste by converting scrap plastic into high-quality pellets, which can be re-used in manufacturing.

Customization options: Plastic granulators offer different cutter designs and screen options, which allows for customization of output size, shape, and consistency.

Cost-effective: Using a plastic granulator reduces the cost of producing new plastic products, as recycled plastic pellets are cheaper than virgin plastic pellets.

Environmentally friendly: Recycling plastic and reducing waste can have a positive impact on the environment, and plastic granulators play a key role in this process.

Ⅴ. Summarize

The importance of plastic pelletizers to the future of the plastics industry and the environment

Plastic pelletizers are vital to the future of the plastics industry and the environment for several reasons:

Reduction of waste: Pelletizers help to reduce plastic waste by processing scrap or waste plastic into high-quality pellets that can be reused for manufacturing new products.

Sustainability: By reusing plastic waste, pelletizers enable the plastics industry to become more sustainable, reducing the need for virgin plastic production. This helps to conserve natural resources and reduce carbon emissions associated with plastic production.

Cost-effective: Using recycled plastic pellets is often less expensive than producing virgin plastic pellets, which reduces the costs associated with plastic production.

Customization: Pelletizers offer customization options in terms of pellet size, shape, and consistency, which enables manufacturers to produce plastic products with specific requirements.

Innovation: The plastics industry depends on innovation to meet the evolving needs of consumers and markets. Pelletizers enable the production of new and innovative plastic products by providing a reliable source of plastic feedstock.

In conclusion, plastic pelletizers are essential to the future of the plastics industry and the environment due to their ability to reduce waste, promote sustainability, reduce costs, provide customization options and facilitate innovation.