Introduction to Plastic Granulators

As market demand for granulation increases, traditional manual granulation methods have proven insufficient. This need gave rise to the plastic granulator, a widely used machine in plastic processing. It transforms plastic sheets or powders into small, uniform granules or pellets suitable for molding and other applications.

Plastic pelletizing machines are highly adaptable and capable of producing granules in various shapes and sizes to match different raw material properties and customer requirements. This versatility makes them essential for modern plastic production and recycling.

The Working Principle of a Plastic Pelletizer

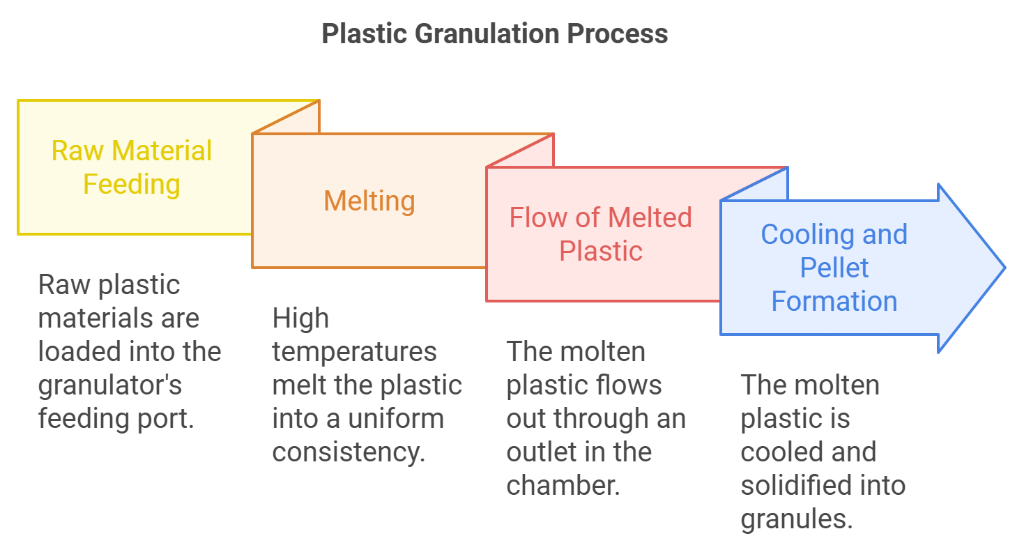

A plastic granulator transforms raw plastic into granules of precise sizes and shapes by utilizing the material's physical and chemical properties. The process involves careful control of temperature, pressure, and rotational speed, along with cooling methods like water or air. Here’s a closer look at the steps involved:

- Raw Material Feeding

The process starts by loading raw plastic materials into the granulator’s feeding port. A feeding wheel guides the material into the machine's main chamber. - Melting

Inside the chamber, high temperatures melt the plastic. The rotating screw continuously stirs the material, ensuring it melts evenly into a uniform consistency. - The Flow of Melted Plastic

Once the molten plastic reaches the required viscosity, it flows out through an outlet in the chamber. - Cooling and Pellet Formation

The molten plastic is cooled, typically with water, to solidify it into granules. The pellets are then dehydrated using vibration and stored in a silo for further use.

A Versatile Solution for Plastic Processing

Plastic Pelletizers are incredibly versatile and capable of handling a wide range of plastics, such as PP, PE, PS, ABS, PA, PVC, PC, POM, EVA, LCP, PET, PMMA, and more. This flexibility makes them ideal for recycling, processing, and granulating various plastic materials, catering to diverse industrial needs.

Plastic Granulator Composition: A Breakdown

The heart of a plastic granulator is its extruder system. This system comprises four key parts: the extrusion system itself, the transmission system, the heating and cooling system, and the control system. Let's break each one down:

1. Extrusion System: This system takes plastic and transforms it into a uniform melt. It includes the screw, barrel, hopper, die head, and mold.

- Screw: This is the workhorse. Made from high-strength, corrosion-resistant alloy steel, the screw's design directly impacts the granulator's efficiency and applications.

- Barrel: A metal seamless tube (usually alloy steel for its heat resistance, compressive strength, wear resistance, and corrosion resistance, or a composite steel pipe lined with alloy steel). Working in tandem with the screw, the barrel pulverizes, softens, melts, plasticizes, de-aers, and compacts the plastic, smoothly feeding the material to the die head. A typical barrel length is 16 times its diameter, ensuring thorough heating and plasticization.

- Hopper: The hopper feeds the plastic into the system. It features a cutting device to regulate material flow, a sight hole for visual monitoring, and a calibration metering device for precise control.

- Die Head and Mold: The die head (an alloy steel inner sleeve and a carbon steel outer sleeve) houses the mold. Its job is to convert the rotating melt into a linear flow, smoothly feeding it into the mold and applying the necessary molding pressure. The plastic, already plasticized and compacted in the barrel, passes through a porous filter plate and into the die's molding cavity. A shunt plate (sleeve) often helps optimize flow and eliminate dead zones where plastic might accumulate. A pressure-equalizing ring minimizes pressure fluctuations during extrusion. The die head also includes adjustment mechanisms to ensure the mold core and sleeve are concentric. Die heads are categorized as oblique (120 degrees) or right-angle (90 degrees) based on the angle between the material flow and the screw's centerline. Heating and temperature-sensing elements are integrated into the die head. The mold itself is secured within the die head and features a core seat, core, and core seat with a central hole for the core wire (if applicable).

2. Transmission System: This system drives the screw, providing the necessary torque and speed. It typically consists of a motor, a reducer, and bearings.

3. Heating and Cooling System: Precise temperature control is crucial for successful extrusion.

- Heating: Most extruders use electric heating (resistance or induction). This externally heats the barrel, bringing the plastic to the required processing temperature.

- Cooling: Cooling removes excess heat generated by the screw's shear friction, preventing plastic decomposition, scorching, or processing difficulties. Small to medium extruders often use air cooling, while larger ones typically employ water cooling or a combination of both. Screw cooling (usually central water cooling) increases solid material conveyance, stabilizes output, and improves product quality. Hopper cooling prevents sticking and blockages.

4. Control System: This system manages the entire process. It includes heating, cooling, and process parameter measurement systems, comprising electrical components, instruments, and actuators (control panel and console). Key functions include:

- Controlling the main and auxiliary machine motors, ensuring appropriate speed and power.

- Monitoring and adjusting temperature, pressure, and flow within the extruder.

- Providing either manual or automatic control of the entire unit.

The electrical control system is broadly divided into transmission and temperature control, managing aspects like temperature, pressure, screw rotation, screw and barrel cooling, product cooling, outer diameter, traction speed, wire arrangement, and maintaining constant tension on the take-up reel. Specific control aspects include:

- Extruder Temperature Control: Maintaining the correct temperature throughout the extruder, considering both external heating and the heat generated by the screw itself. Accurate thermocouple placement and temperature control instrumentation are essential.

- Extruder Pressure Control: Monitoring die pressure (often indirectly via screw load measurement) to detect and address pressure fluctuations that can affect extrusion quality.

- Screw Speed Control: Precise screw speed control is vital for consistent output and product quality. A wide speed regulation range and high-speed stability are desirable.

- Outer Diameter Control: Maintaining consistent outer diameter requires controlling wire core dimensions, extrusion temperature, screw speed, and traction line speed. Online outer diameter detection and feedback control are crucial for high-speed extrusion lines.

- Overall Machine Automation: This encompasses features like start-up temperature interlocks, pressure protection, synchronized extrusion and traction, synchronized take-up and traction, online outer diameter control, and single-machine and complete-machine component tracking.

This detailed breakdown provides a comprehensive understanding of the plastic granulator's composition and functionality.

Choose Aceretech Machinery to Create a Sustainable Future Together

Aceretech Machinery stands at the forefront of the plastic recycling industry, providing advanced plastic recycling machines and granulators that significantly enhance production efficiency. Our state-of-the-art machines are engineered to convert various plastic waste into high-quality granules, meeting the diverse needs of our customers. With a focus on innovation and reliability, Aceretech ensures that each granulator is tailored to optimize performance, reduce energy consumption, and deliver consistent results. This commitment to excellence positions us as a trusted partner in the plastic processing sector.

Our plastic granulators are designed with versatility in mind, capable of handling a wide range of materials, including PP, PE, PS, and more. By integrating cutting-edge technology into our equipment, Aceretech Machinery not only improves the granulation process but also contributes to sustainable practices in plastic recycling. We invite you to explore our comprehensive solutions that empower your operations and support environmental responsibility. Contact us today to discover how we can elevate your production capabilities!

Request a Quote